Application of hyperbranched polymer in antistatic agent on flame retardant conveyor belt

A technology of hyperbranched polymers and antistatic agents, applied in polyester coatings, coatings, etc., to achieve the effects of low viscosity, simple synthesis process, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

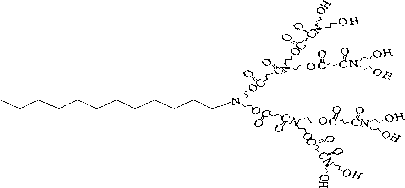

Method used

Image

Examples

Embodiment 1

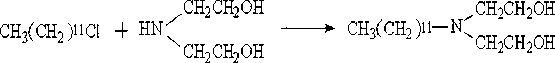

[0049] (1) Weigh 12.799g of dodecane chloride and put it into a three-necked flask with a magnetic stirrer and a reflux condenser, add 7.749g of ethanol, stir and heat up to 70 degrees Celsius; add 6.571g of diethanolamine dropwise into the three-necked flask, Stir for 0.5 hour, then add 2.501 g of NaOH, heat up until reflux occurs, and keep the reaction for 4 hours. Purify the crude product and distill it under reduced pressure to obtain N,N-dihydroxyethyl dodecylamine;

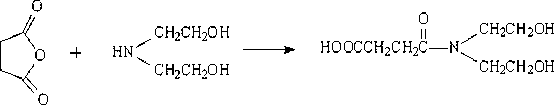

[0050] (2) Weigh 10.007g of succinic anhydride and 10.514g of diethanolamine, first dissolve diethanolamine in 30 mL DMAc, and pour it into a three-neck flask with a magnetic stirrer after dissolving; then add succinic anhydride with 40 mL of DMAc After dissolving, pour it into a constant pressure dropping funnel, then slowly add it dropwise into a three-neck flask, stir while adding dropwise, add dropwise for about one hour, and react at room temperature for 3 hours to obtain AB 2 type monomer;

[0051] (...

Embodiment 2

[0055] (1) Weigh 12.799 g of chlorododecane into a three-necked flask equipped with a magnetic stirrer and a reflux condenser, add 7.749 g of ethanol, stir and heat up to 70 degrees Celsius; add 6.571 g of diethanolamine dropwise into the three-necked flask, Stir for 0.5 hour, then add 2.501 g of NaOH, heat up until reflux occurs, and keep the reaction for 4 hours. Purify the crude product and distill it under reduced pressure to obtain N,N-Dihydroxyethyl dodecylamine.

[0056] (2) Weigh 10.007 g of succinic anhydride and 10.514 g of diethanolamine, first dissolve diethanolamine in 30 mL DMAc, and pour the solution into a three-neck flask with a magnetic stirrer; then add succinic anhydride with 40 mL DMAc After dissolving, pour it into a constant pressure dropping funnel, then slowly add it dropwise into a three-neck flask, stir while adding dropwise, add dropwise for about one hour, and react at room temperature for 3 hours to obtain AB 2 type monomer.

[0057] (3) Weigh 4...

Embodiment 3

[0061] (1) Weigh 12.799 g of chlorododecane into a three-necked flask equipped with a magnetic stirrer and a reflux condenser, add 7.749 g of ethanol, stir and heat up to 70 degrees Celsius; add 6.571 g of diethanolamine dropwise into the three-necked flask, Stir for 0.5 hour, then add 2.501 g of NaOH, heat up until reflux occurs, and keep the reaction for 4 hours. Purify the crude product and distill it under reduced pressure to obtain N,N-Dihydroxyethyl dodecylamine.

[0062] (2) Weigh 10.007 g of succinic anhydride and 10.514 g of diethanolamine, first dissolve diethanolamine in 30 mL DMAc, and pour the solution into a three-neck flask with a magnetic stirrer; then add succinic anhydride with 40 mL DMAc After dissolving, pour it into a constant pressure dropping funnel, then slowly add it dropwise into a three-neck flask, stir while adding dropwise, add dropwise for about one hour, and react at room temperature for 3 hours to obtain AB 2 type monomer.

[0063] (3) Weigh 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com