Patents

Literature

42results about How to "Leak quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of mineral graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe

The invention relates to a preparation method of a mineral graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe. The pipe is prepared from the following raw materials: 100 parts of ultra-high molecular weight polyethylene, 2-5 parts of nano-graphene sheets, 5-10 parts of a coupling agent, 0.1-1 part of a foaming agent, 0.1-1 part of a compatibilizer, 1-2 parts of a lubricating agent, 6-10 parts of a halogen-free flame retardant, 3-6 parts of an antistatic agent, 2-4 parts of a flow modifier, 1-3 parts of a nucleating agent, and the like; the graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe is prepared by the processes of extruding, sizing, and the like. According to the preparation method, nano-graphene, the antistatic agent and the flame retardant are dispersed into ultra-high molecular weight polyethylene resin medium gaps by means of the coupling agent, the compatibilizer, the flow modifier, the lubricating agent, the nucleating agent, and the like; the nano-graphene sheets have significant synergistic flame retardation after being compounded with the flame retardant, and can reduce the resistivity of the pipe after being compounded with the antistatic agent. The prepared pipe has the characteristics of being light in weight, high in strength, flame-retardant, antistatic, and the like, thus being used in the operating environments such as coal mines, downhole and mines in which a great deal of gas exists.

Owner:JIUJIANG UNIVERSITY

Preparation method of composite antistatic agent for fiber fabric

The invention discloses a preparation method of a composite antistatic agent for a fiber fabric. The composite antistatic agent for the fiber fabric in the preparation method comprises the following components: a butanol phosphate ester antistatic agent, a terminal hydroxyl hyperbranched antistatic agent, a terminal carboxyl hyperbranched antistatic agent and a terminal quaternary ammonium salt hyperbranched antistatic agent; and the preparation method comprises the following steps: firstly, respectively preparing the butanol phosphate ester antistatic agent, the terminal hydroxyl hyperbranched antistatic agent, the terminal carboxyl hyperbranched antistatic agent and the terminal quaternary ammonium salt hyperbranched antistatic agent; and mixing the four antistatic agents to prepare the composite antistatic agent for the fiber fabric. The preparation method is simple and feasible; and the prepared antistatic agent has a good antistatic effect, good heat resistance and good acid and alkali resistance.

Owner:SUZHOU CHENHENG WEAVING

Healthy polyolefine foam material and preparation method thereof

The invention relates to a healthy polyolefine foam material and a preparation method thereof. The healthy polyolefine foam material is prepared from the following original auxiliary materials subjected to mixing, smelting, extrusion, preheating and foaming in parts by weight: 70-100 parts of polyolefine resin, 20-50 parts of anion functional master batch, 15-30 parts of hydrophilic functional master batch, 1-5 parts of a foaming agent, 1-5 parts of a cross-linking agent and 0-5 parts of color master batch. According to the healthy polyolefine foam material provided by the invention, the anion mineral materials and hydrophilic fullerene compounds are added into the formula, so that the foam material has the advantages of air purifying, surface oil contamination resistance, electrostatic prevention and the like; the anion concentration of ambient environment can be effectively increased in virtue of the pyroelectricity and piezoelectricity of the anion mineral material; besides, the hydrophilic groups of the hydrophilic fullerene compounds can form hydrogen bonds with water, so that the contact of pollutants and the polyolefine surface is prevented, accumulated static charges can be leaked quickly, and the antistatic purpose can be further achieved.

Owner:TAISHAN SPORTS IND GRP +1

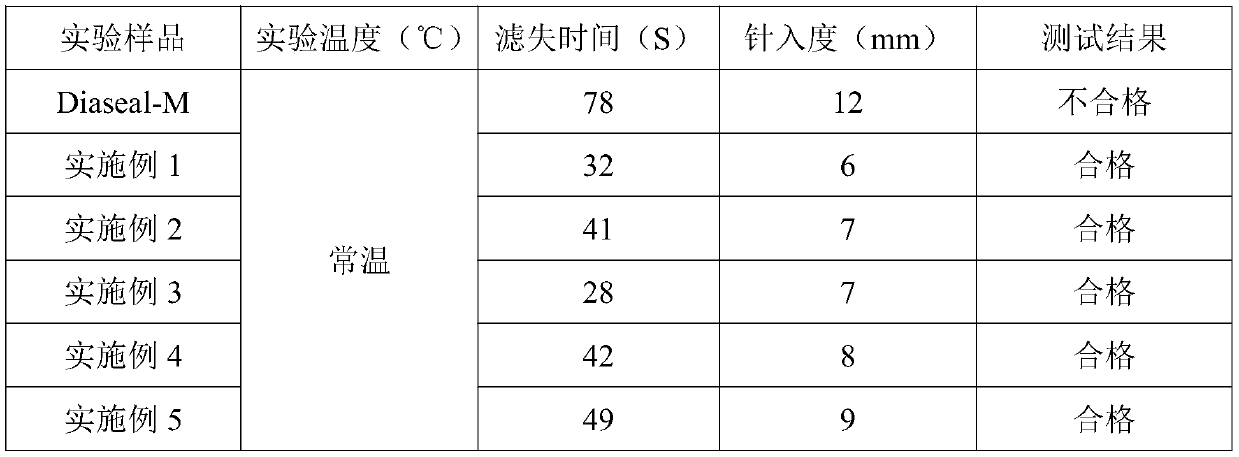

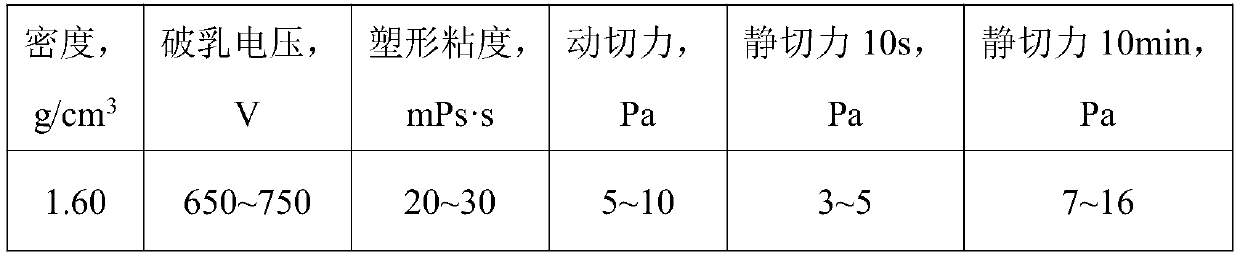

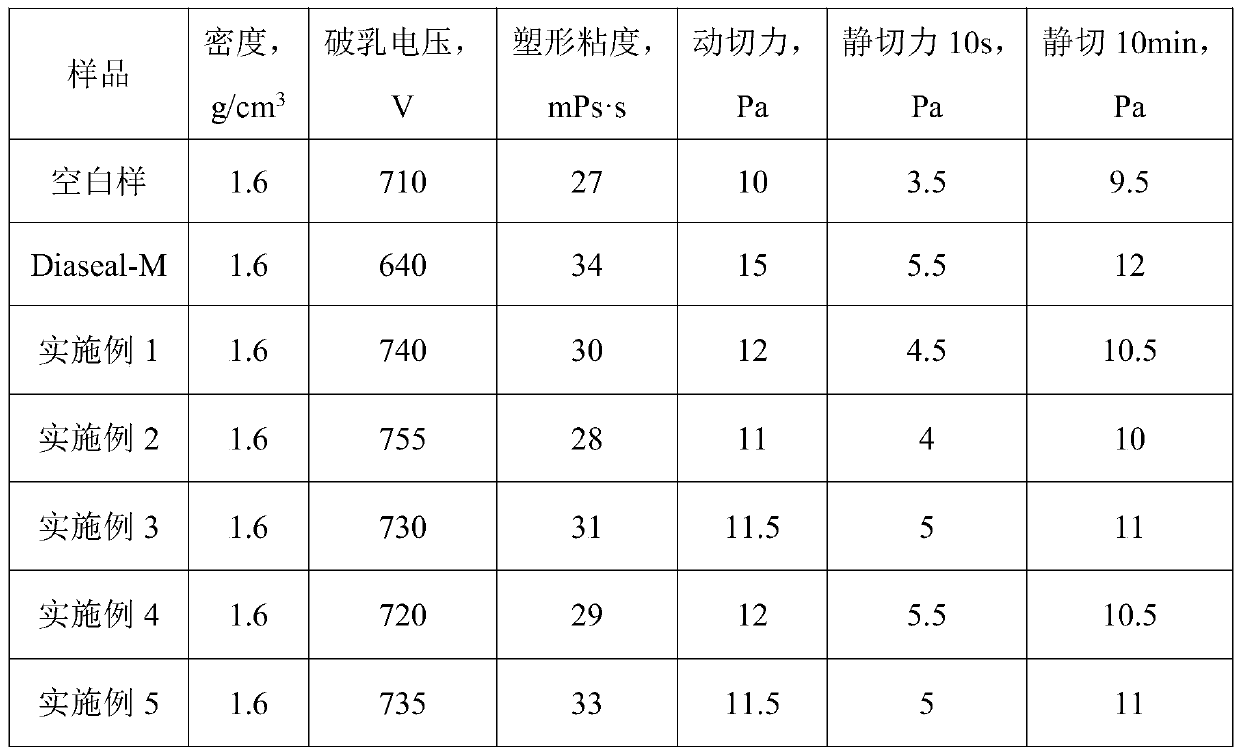

High-filtration-loss plugging agent specially used for oil-based drilling fluid

ActiveCN110819322AImprove pressure bearing capacityEffective filtrationDrilling compositionFiltrationPolyamide fibers

The invention discloses a high-filtration-loss plugging agent specially used for oil-based drilling fluid. The high-filtration-loss plugging agent is prepared from, by weight, 5-10 parts of fiber, 40-70 parts of a porous inert material, 10-25 parts of a percolating material and 5-10 parts of a filter aid; the porous inert material is a mixture of ceramic powder with the particle size of 180 meshesand ceramic powder with the particle size of 250 meshes, and the weight ratio of the 180-mesh ceramic powder to the 250-mesh ceramic powder is (4-6): (3-5); the percolating material is a mixture of zeolite powder with the particle size of 100 meshes and zeolite powder with the particle size of 150 meshes, and the weight ratio of the 100-mesh zeolite powder to the 150-mesh zeolite powder is (2-4):(4-7); the fiber is polyamide fiber, the length-diameter ratio is 5-50: 1, and the diameter is 0.5-15 microns; the filter aid is lime powder with the particle size of 200 meshes. The above componentsare uniformly mixed to obtain the high-filtration-loss plugging agent specially used for oil-based drilling fluid. The plugging agent disclosed by the invention is prepared by mixing various materials such as the fiber, the porous inert material, the percolating material and the filter aid, and is wide in application range, simple in plugging construction, high in safety and quick in effect.

Owner:ASTAR PETROTECH

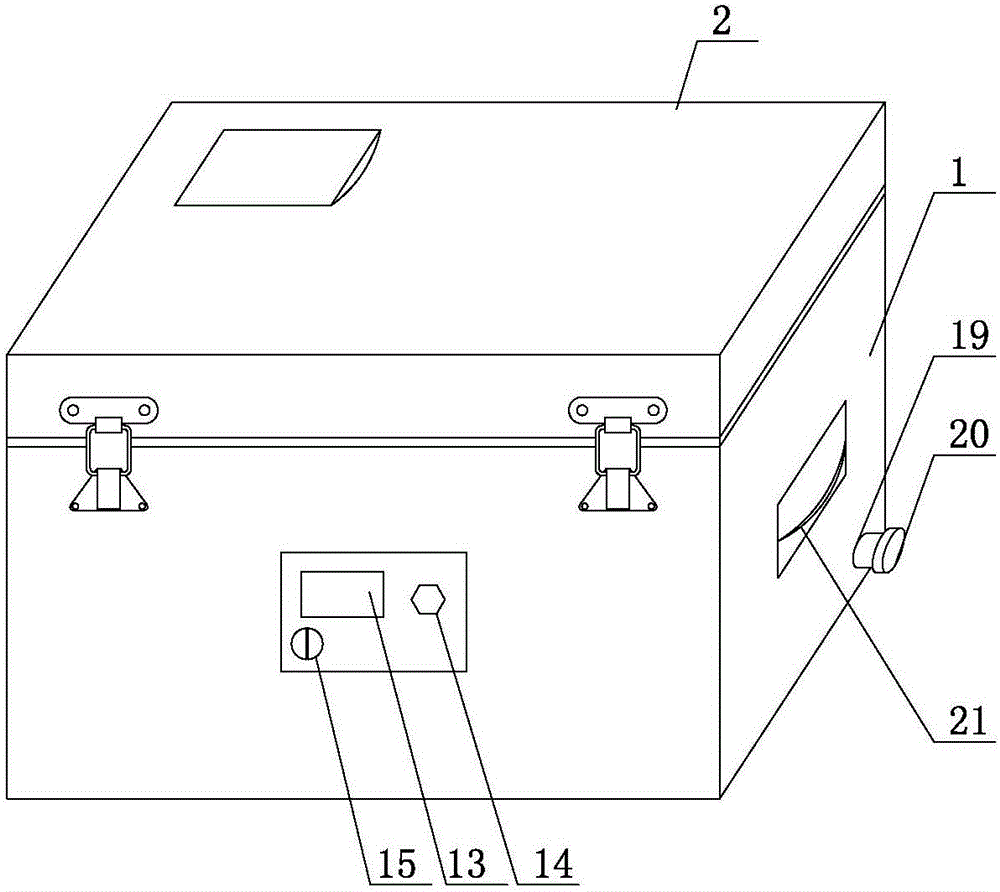

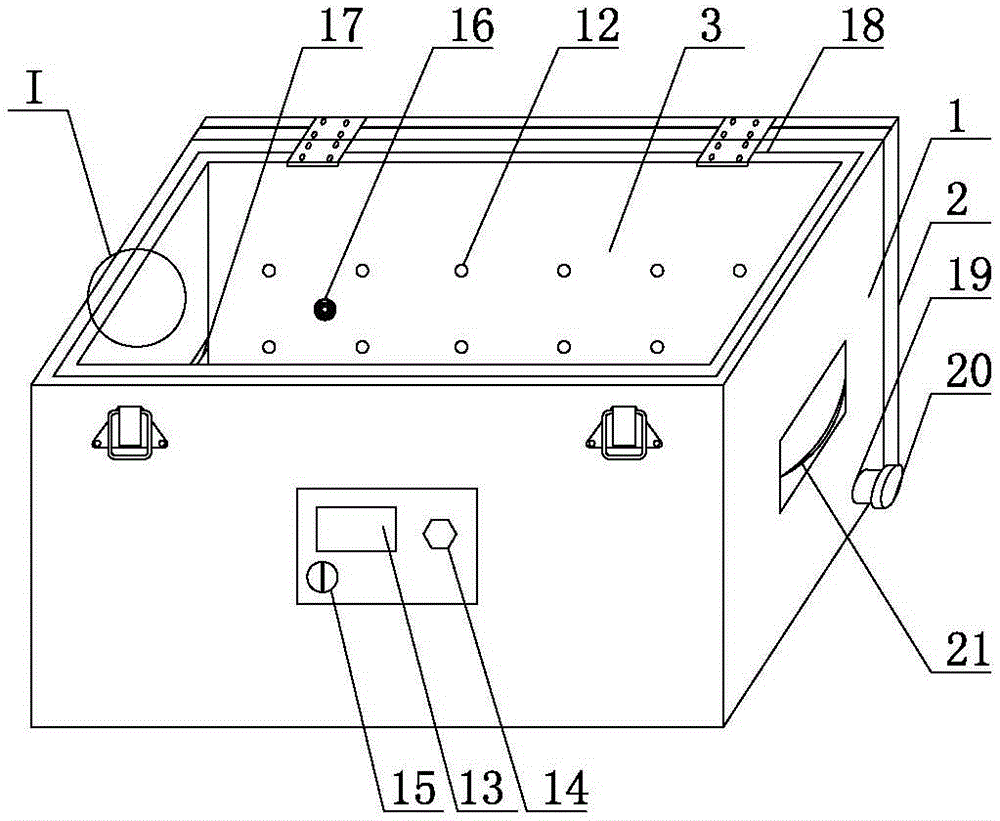

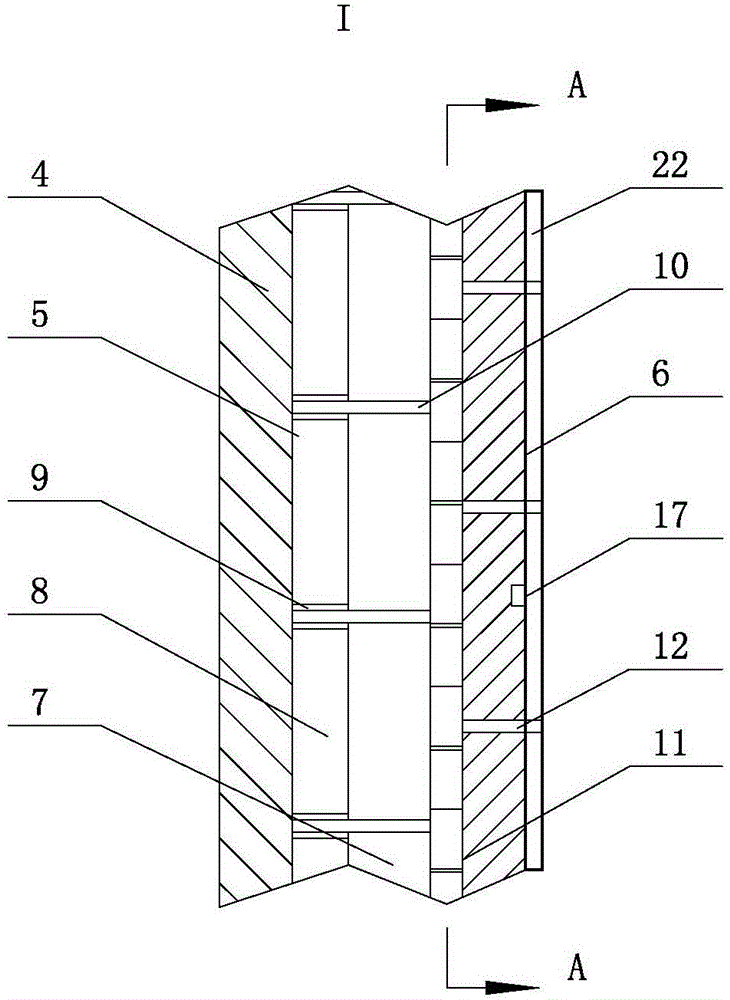

Intelligent temperature control early warning food security insulation box

ActiveCN104787484AHigh strengthReduce weightDomestic cooling apparatusLighting and heating apparatusTemperature controlThermal insulation

The invention discloses an intelligent temperature control early warning food security insulation box. The intelligent temperature control early warning food security insulation box comprises a box body, an upper cover and an insulation inner cavity formed by the box body and the upper cover; the box body and the upper cover are each sequentially provided with a shell, a vacuum thermal insulation layer and a cavity wall from exterior to interior; the inner side of the upper cover is provided with a pressing sheet, and the pressing sheet is connected with the upper cover through a spring; the longitudinal direction and the transverse direction of the inner wall of the box body are each provided with an elastic fixing belt, and therefore objects can be fixed in a cross traction mode after the object is well put into the box body. The intelligent temperature control early warning food security insulation box is used for solving the defects in the prior art, a detachable support air channel is arranged in the shell of the box body, the maintenance is facilitated, the air flow in the thermal insulation inner cavity is enhanced, and the thermal insulation effect of the objects is improved.

Owner:CHINA RAILWAYS CORPORATION

Graphene island fiber and manufacturing method thereof

ActiveCN109706546AStimulate vitalityTo promote metabolismElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsCvd grapheneSurface resistivity

The invention relates to a graphene island fiber and a manufacturing method thereof. The manufacturing method comprises the following steps of preparing graphene master batch from a functional graphene material through esterification polymerization, and then blending and melting the graphene master batch and PET to obtain a graphene island composition; melting and blending the graphene island composition and a soluble polyester marine composition to obtain graphene island protofilaments, and conducting working processes of bundling, drafting, tension heat setting, curling, oiling, relaxation heat setting, cutting and the like to obtain the graphene island fiber. The graphene island fiber can reduce the surface resistivity of a material, quickly release generated electrostatic charge, endowthe surface of the material with certain lubricity at the same time and further reduce the friction coefficient so as to inhibit and reduce the generation of electrostatic charge. The biocompatibility is high, and the graphene island fiber is a non-toxic, environment-friendly and efficient functional textile and has the far infrared function, antibacterial function, bacteriostatic function and antistatic function of graphene fibers.

Owner:SHANGHAI DEFULUN CHEM FIBER

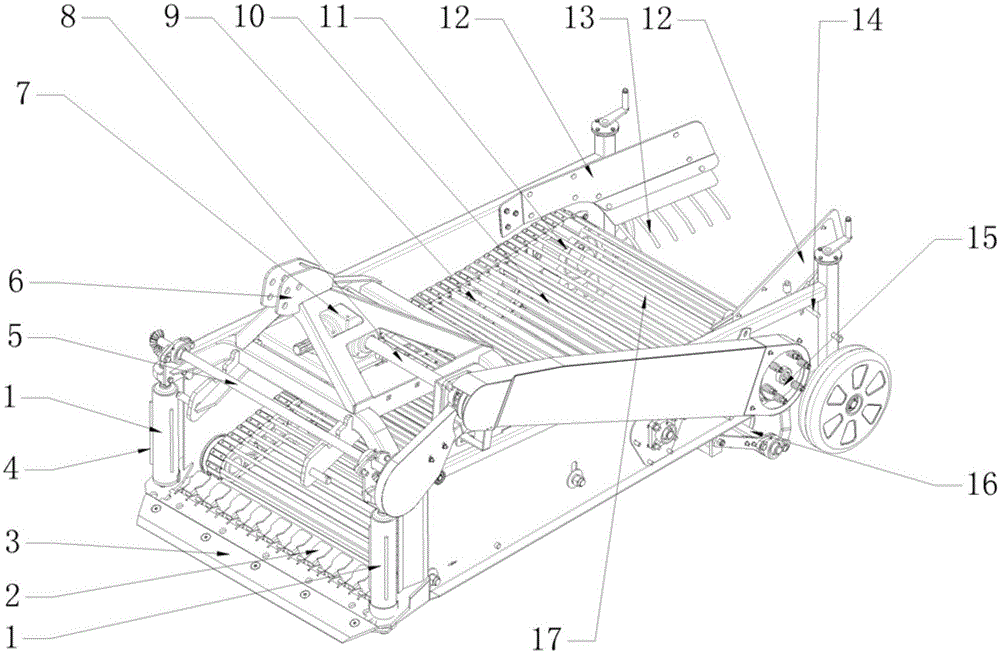

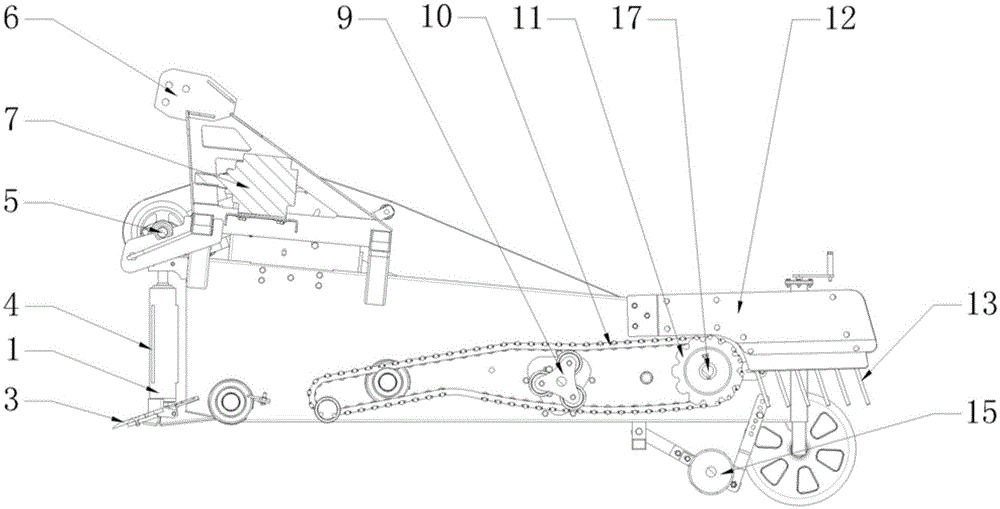

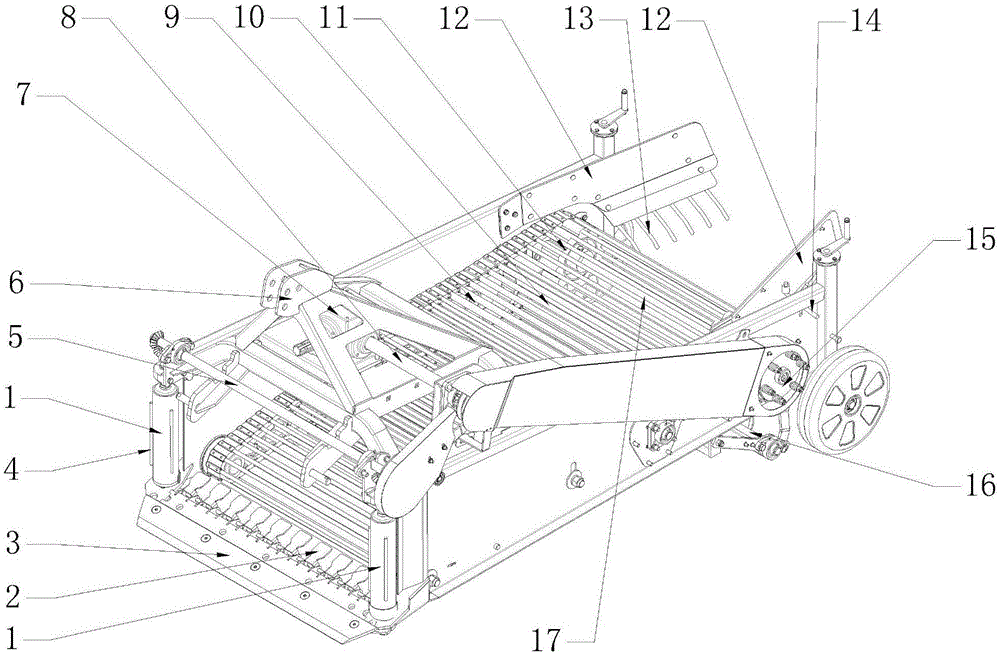

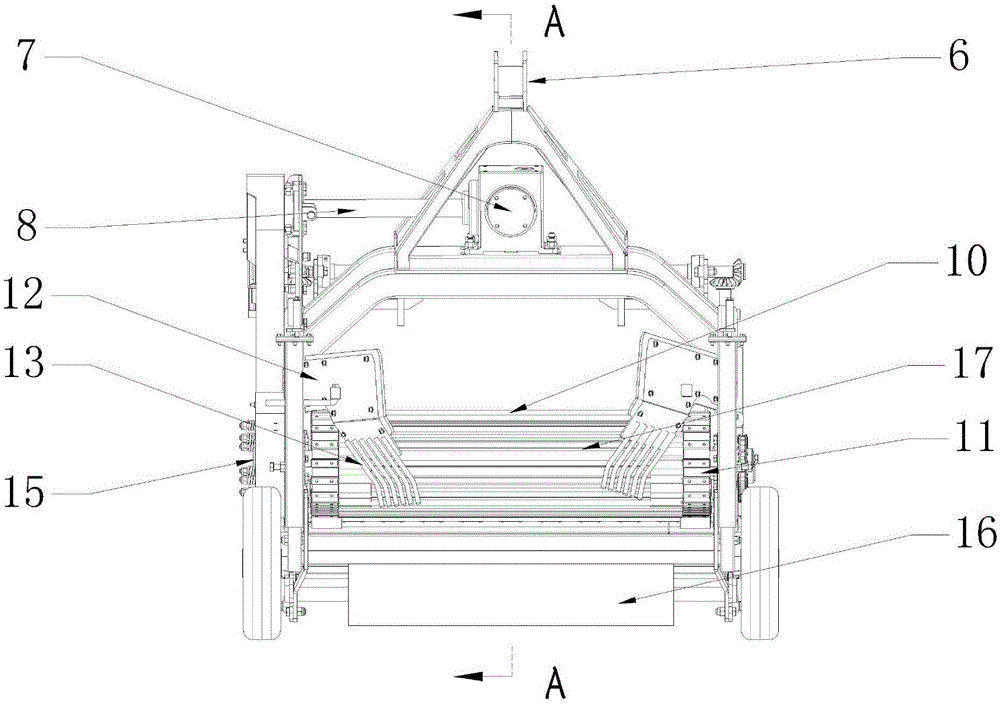

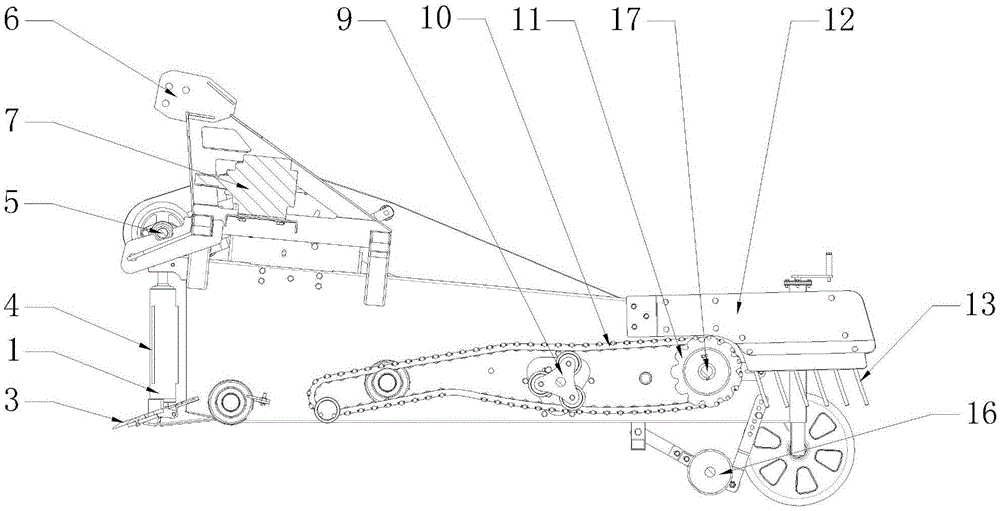

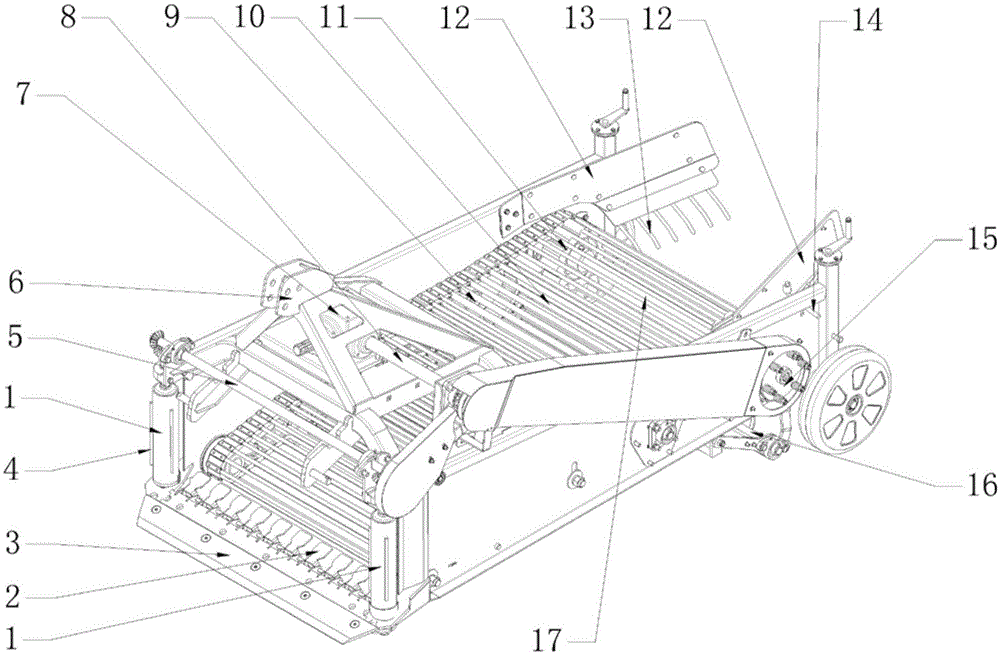

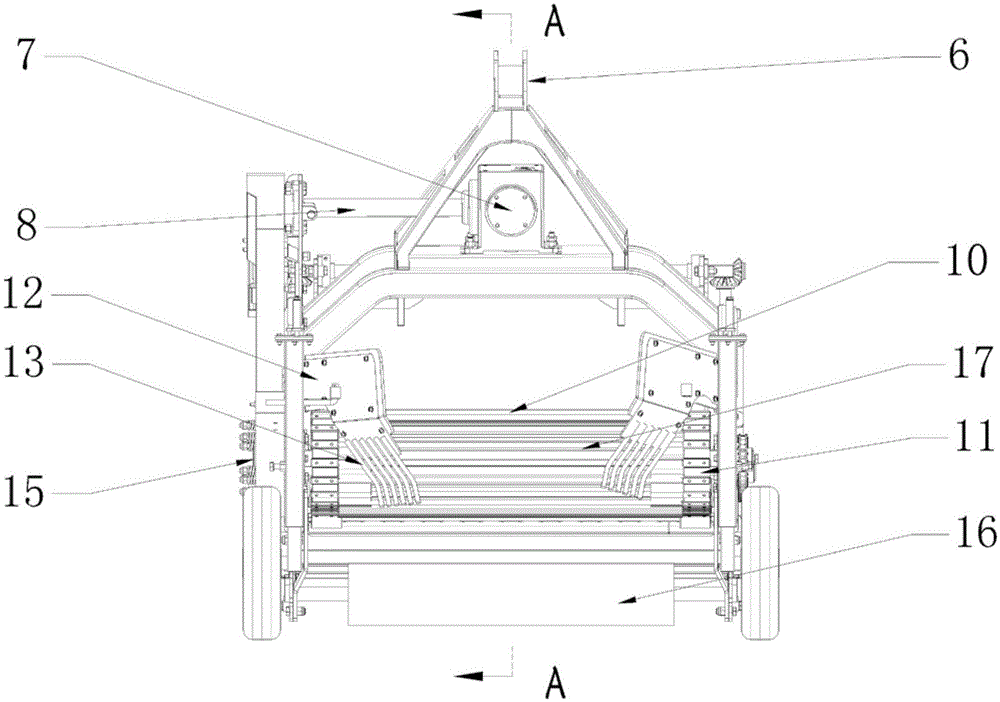

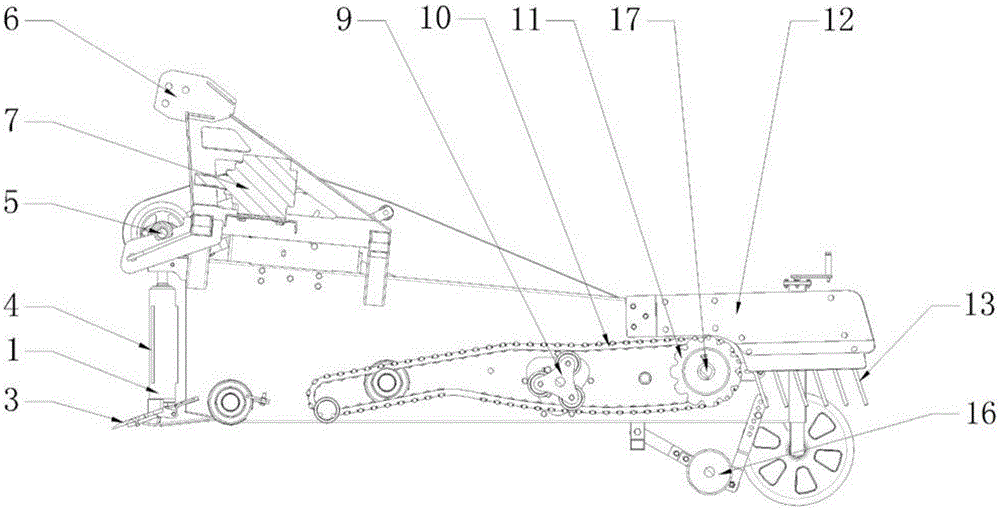

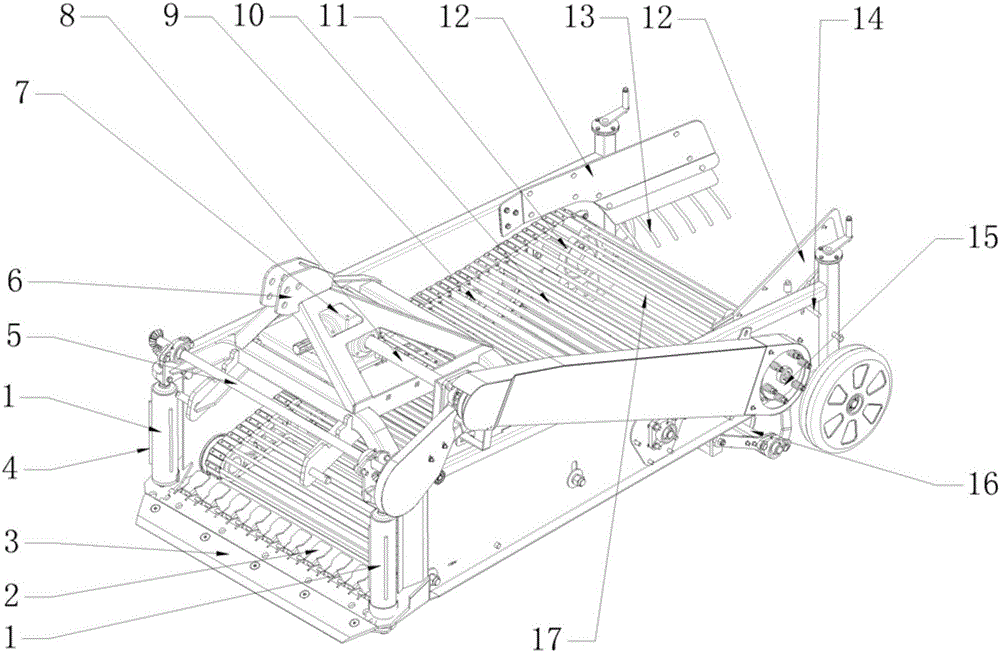

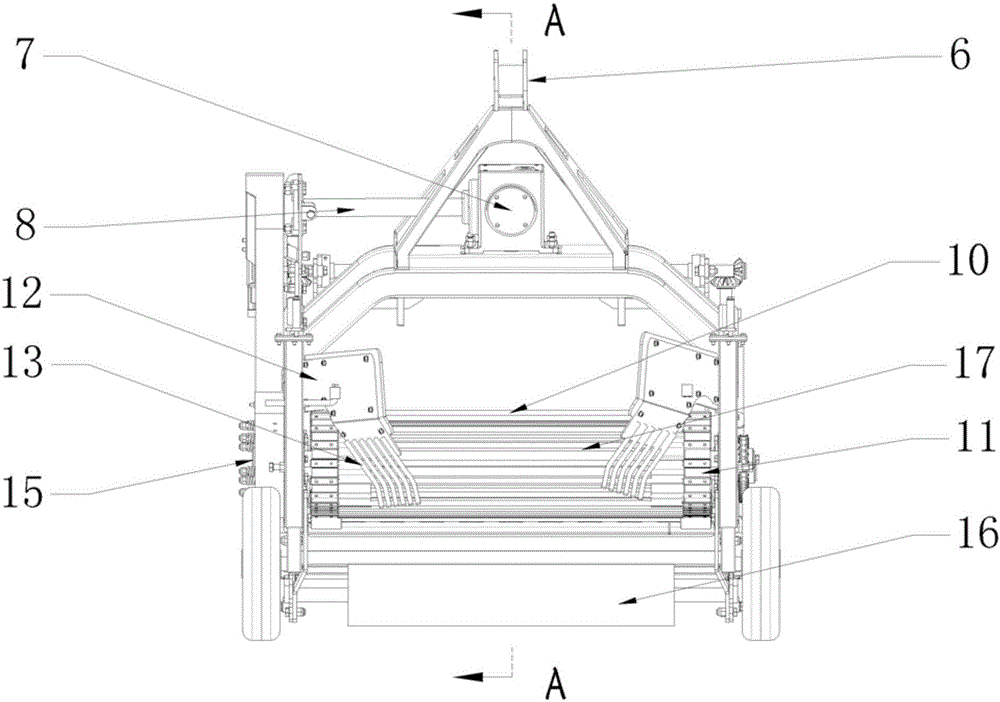

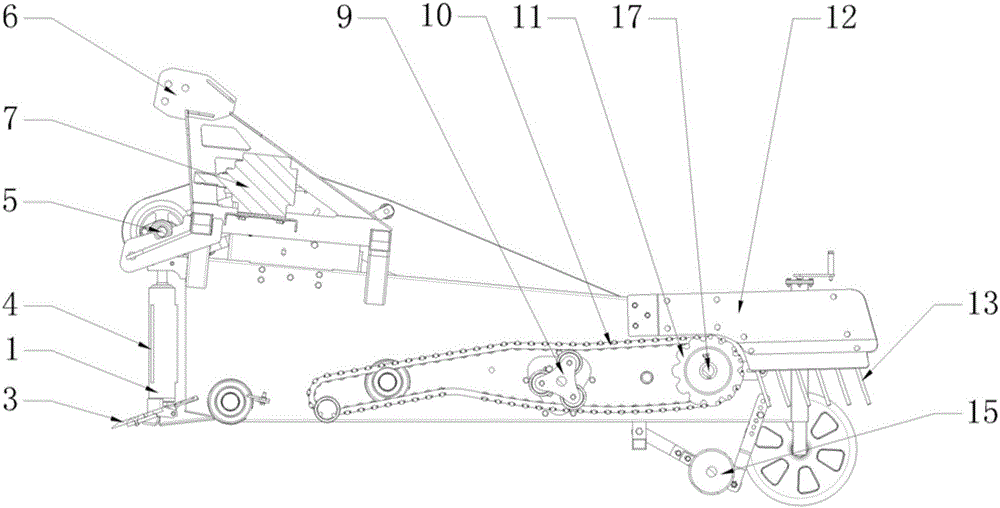

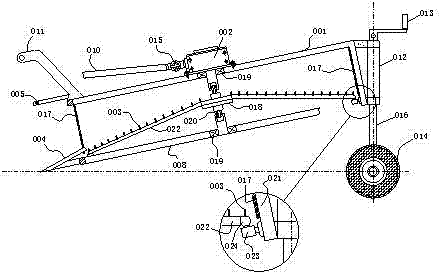

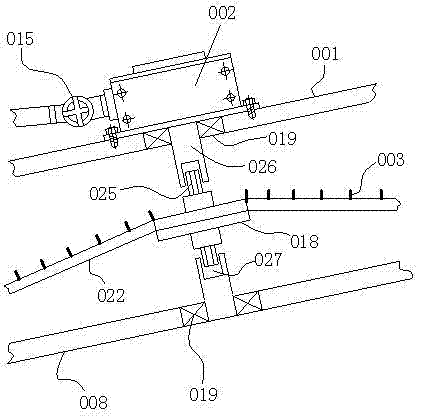

Harvester for rhizomatic crops

The invention relates to a harvester for rhizomatic crops. The harvester comprises a rack, a scraper knife located at the front end of the rack, and a vibration screen located on the rear middle portion of the rack. Vertical rotating rolls are arranged at the two sides of the front end of the rack respectively, clearances are reserved between the rotating rolls and the rack, and the two rotating rolls are connected with a power shaft. At least one pair of annular secondary-primary sealing pieces is arranged in each rotating roll and located in the clearance between each bearing pedestal and a corresponding bearing pedestal shaft, the outer portions of the secondary-primary sealing pieces are in interference fit with the bearing pedestals, and the bearing pedestal shafts are arranged in center holes of the secondary-primary sealing pieces. A rear ridge pressing roll is arranged below the rear portion of the rack, and is hinged to the rack. The harvester is suitable for multiple soil types such as sandy soil, sandy loam and intermediate-viscidity soil; a tri-wheel vibration system is adopted, so that the separation effect of the crops and the soil is good, the harvesting rate is higher than 99%, and the breakage rate is lower than 1%. Due to the design of the rear ridge pressing roll and a collecting baffle, damage to the crops is reduced, the crops are centralized after falling to the ground, and harvesting is easy. Grass blocking is avoided, soil leakage is fast, and the service life is long.

Owner:刘文勋

Rhizomatic crop harvester

The invention relates to a rhizomatic crop harvester. The rhizomatic crop harvester comprises a rack, a scraper knife located at the front end of the rack and a vibrating screen located on the rear middle portion of the rack; the two sides of the front end of the rack are each provided with a vertical rotating roller, gaps are reserved between the rotating rollers and rack, and the rotating rollers are connected with power shafts; at least one pair of annular child and mother sealing parts are arranged in the rotating rollers and located in gaps between bearing pedestals and bearing pedestal shafts, the exteriors of the child and mother sealing parts are in interference fit with the bearing pedestals, and the bearing pedestal shafts are arranged in central holes of the child and mother sealing parts; a rear ridge roller is arranged under the rear portion of the rack and hinged to the rack. The harvester is suitable for various soil types such as sandy soil, sandy loam soil and medium-viscosity soil; a three-wheel vibrating system is adopted, so that the crop and soil separation effect is good, the harvesting rate is higher than 99 percent, and the breakage rate is lower than 1 percent; the rear ridge roller and a collection baffle are designed, so that crop damage is reduced, crops are concentrated after falling to the ground and easy to harvest; grass cannot block the harvester, soil leakage is fast, and the service life is long.

Owner:刘文勋

Crop harvester

A crop harvester comprises a machine frame, a shovel blade located at the front end of the machine frame, and a vibrating screen located on the rear middle portion of the machine frame, wherein vertical rotary rollers are arranged at the two sides of the front end of the machine frame respectively, gaps are reserved between the rotary rollers and the machine frame, and the two rotary rollers are connected with a power shaft; at least one pair of annular male and female sealing parts is arranged in each rotary roller and located in a gap between a bearing seat and a bearing seat shaft, the outer sides of the male and female sealing parts are in interference fit with the bearing seat, and the bearing seat shaft is arranged in center holes of the male and female sealing parts; a rear ridge roller is arranged below the rear portion of the machine frame and hinged to the machine frame. The harvester is suitable for various soil types including sandy soil, sandy loam and medium clay soil; by the adoption of a three-wheel vibration system, crop and soil separating effect is good, yield rate is higher than 99%, and damage rate is lower than 1%; through the design of the rear ridge roller and a collection baffle, damage to crops is reduced, and crops are gathered after falling onto the ground and are easy to harvest; weed blocking is avoided, soil leakage is quick, and service life is long.

Owner:刘文勋

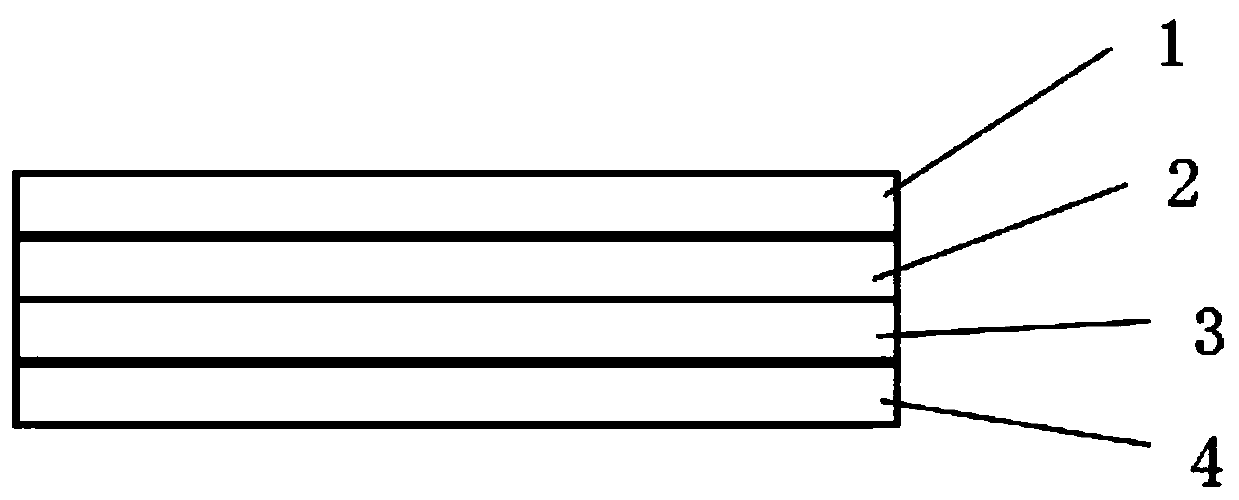

Antistatic organic-silicon synthetic leather and preparation method thereof

InactiveCN109826021AImprove scratch resistanceReduce adsorptionTextiles and paperSurface layerWear resistant

The invention relates to an antistatic organic-silicon synthetic leather. The synthetic leather comprises a surface layer, a face layer, a bottom layer and a base material layer from top to bottom insequence, the surface layer is acrylamide hydrogel, and the face layer comprises, by weight, 15-65 parts of vinyl silicon resin, 10-25 parts of methyl vinyl silicone oil, 5-20 parts of a cross-linkingagent, 0.1-1.2 parts of a platinum catalyst, 0.01-0.4 part of an inhibitor, 5-25 parts of filler and 0-5 parts of color paste. The bottom layer comprises, by weight, 30-70 parts of base glue, 5-20 parts of vinyl silicon resin, 0.1-1.2 parts of a platinum catalyst, 0.01-0.4 part of an inhibitor, 5-15 parts of a cross-linking agent, 5-25 parts of filler and 0-5 parts of color paste. The prepared organic-silicon synthetic leather has the advantages of good antistatic, wear-resistant, scraping-resistant, scratch-resistant, soft and smooth performance, and dust suction can be reduced.

Owner:苏州煜之辉智能科技有限公司

Preparation method of carbon nanotube reinforced light-weight wood-plastic composite material

The invention relates to a preparation method of a carbon nanotube reinforced light-weight wood-plastic composite material. The composite material is composed of the following raw materials in percentage by mass: 30-70% of plastic matrix, 30-70% of plant powder, 0.5-3% of carbon nanotube, 3-8% of coupling agent, 0.1-1% of foaming agent, 0.1-1% of compatibilizer, 1-3% of lubricant, 2-4% of toughener and 0.01-0.1% of peroxide and other functional aids. By using the coupling agent, dispersing agent, lubricant and other aids, the small amount of carbon nanotubes are dispersed in both a matrix phase and a wood powder-plastic interface phase as well as in medium gaps; and the right amount of foaming agent is added to realize micro foaming treatment so as to reduce the density of the composite material, thereby enduing the wood-plastic composite material with the favorable characteristics of light weight and high strength. The prepared wood-plastic composite material has the advantages of no toxicity, water resistance, safety, low price and the like, has the favorable characteristics of light weight, high strength, electrostatic prevention and the like, and widens the wood-plastic composite material service environment and application range, thereby having wide economic prospects and social benefits.

Owner:JIUJIANG UNIVERSITY

Processing method of spunlace non-woven fabric

The invention provides a processing method of spunlace non-woven fabric. The spunlace non-woven fabric comprises the following components in parts by weight of 20-30 parts of polyester, 20-30 parts of wood pulp fibers, 5-10 parts of antistatic fibers, 10-20 parts of viscose fibers and 10-20 parts of alginate fibers. A fiber web is soaked in a water solution with hydrogen peroxide content of 30%, washing and dewatering are conducted after soaking, and the antibacterial effect of the non-woven fabric can be effectively improved; meanwhile, a certain bleaching effect can be achieved, the wood pulp fibers of coniferous wood fibers are added, the overall texture of the non-woven fabric can be effectively improved, and the use hand feeling is improved; and the alginate fibers are added, so that the water absorption performance of the non-woven fabric can be effectively improved, and the use is convenient.

Owner:应城市天润产业用布有限责任公司

Preparation technology of hydrophilic stain-resisting textile fabric

InactiveCN109914099APromote absorptionLeak quicklyFibre typesTextile treatment machine arrangementsFiberPolyester

The invention discloses a preparation technology of a hydrophilic stain-resisting textile fabric. The hydrophilic stain-resisting textile fabric is formed by compositing two textile fabrics made frompolyester fiber materials. The technology comprises the steps that the polyester fiber textile fabrics are subjected to rubbing, cooking, grinding and a series of pretreatment, the whole fabric is soft and fluffy and easy to process, various auxiliaries can be absorbed in the follow-up steps, hydrophilic modification is performed on the fabric, hydrophilic groups are introduced into the polyesterfiber structure in a grafting copolymerization mode, and therefore the whole wet permeability is improved; then, stain-resisting modification is performed, silver ions are fixed to nodes of polyesterfiber, the long-acting antibacterial effect is achieved, finally, anti-static modification is performed, the prepared mixing solution is sprayed to the side face A of the polyester fiber textile fabric to form a single-molecule conductive film, static charges on the polyester fiber are rapidly leaked to achieve the antistatic effect, and according to the cooperation and promoting effect of the steps, the hydrophilic stain resistance is achieved sufficiently.

Owner:宁波博洋家纺集团有限公司

Rhizomatic crop harvester

The invention relates to a rhizomatic crop harvester. The rhizomatic crop harvester comprises a rack, a scraper knife located at the front end of the rack and a vibrating screen located on the rear middle portion of the rack; the two sides of the front end of the rack are each provided with a vertical rotating roller, and gaps are reserved between the rotating rollers and rack; at least one pair of annular child and mother sealing parts are arranged in the rotating rollers and located in gaps between bearing pedestals and bearing pedestal shafts, the exteriors of the child and mother sealing parts are in interference fit with the bearing pedestals, and the bearing pedestal shafts are arranged in central holes of the child and mother sealing parts; the scraper knife is in the shape of a trapezoid, a knife edge and a knife back serve as the two bottom edges of the trapezoid, and the knife back is longer than the knife edge; an outer transmission wheel of the vibrating screen is fixed on a side plate of the rack through a flange, and a sliding groove structure for fixing the flange is arranged on the side plate of the rack and comprises a transmission shaft position regulation groove and bolt position regulation grooves. The harvester is suitable for various soil types, the crop and soil separation effect is good, the harvesting rate is higher than 99 percent, and the breakage rate is lower than 1 percent; crops are concentrated after falling to the ground and easy to harvest, grass cannot block the harvester, and the service life is long.

Owner:刘文勋

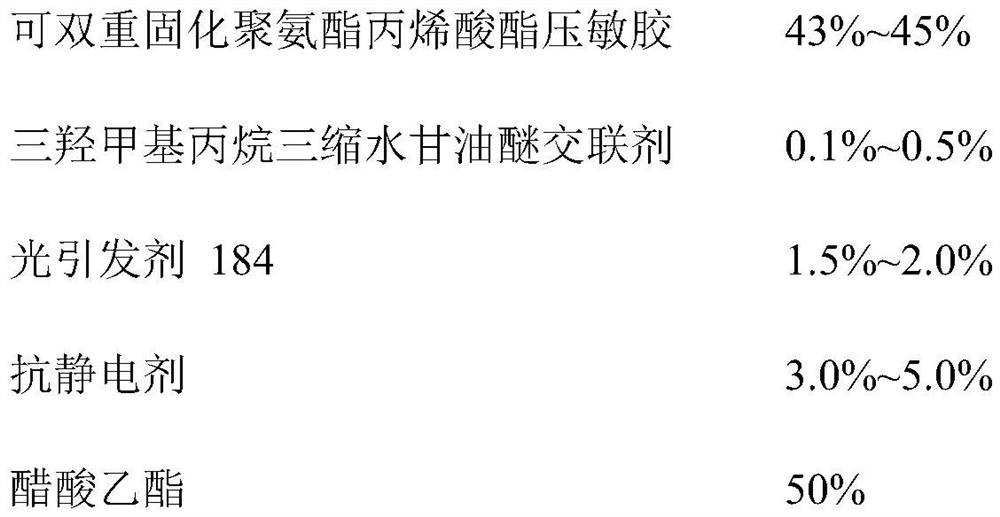

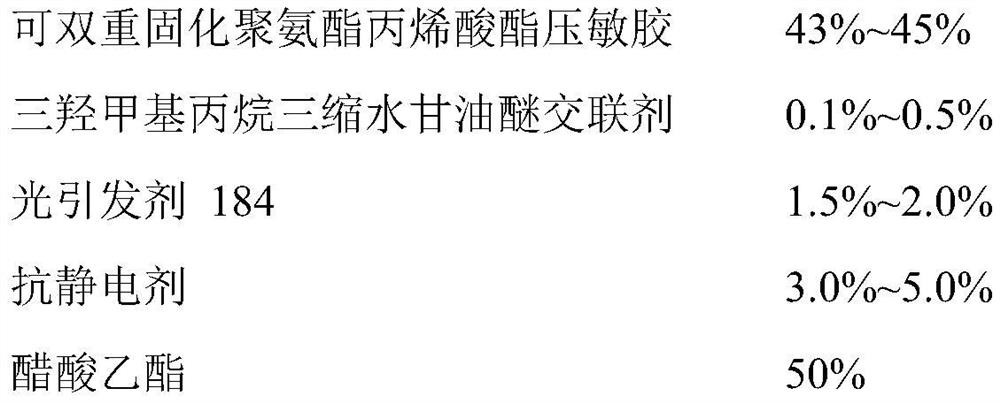

UV viscosity-reducing adhesive with antistatic effect and preparation method of viscosity-reducing adhesive

PendingCN113861928AGood viscosity and interfacial adhesionImprove cohesive strength and interfacial bonding strengthPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesAdhesiveDibenzoyl Peroxide

The invention discloses a UV viscosity-reducing adhesive with an antistatic effect and a preparation method of the viscosity-reducing adhesive. The UV viscosity-reducing adhesive is prepared from the following materials in percentage by mass: 43 to 45 percent of dual-curable polyurethane acrylate pressure-sensitive adhesive, 0.1 to 0.5 percent of trimethylolpropane triglycidyl ether cross-linking agent, 1.5 to 2.0 percent of photoinitiator 184, 3.0 to 5.0 percent of antistatic agent and 50 percent of ethyl acetate. The dual-curable polyurethane acrylate pressure-sensitive adhesive is prepared by adopting a free radical polymerization process to carry out random copolymerization and then carrying out addition polymerization: 16 to 20 parts of n-butyl acrylate, 21 to 25 parts of 2-ethylhexyl acrylate, 8 to 10 parts of hydroxyethyl acrylate, 4 to 5 parts of acrylic acid, 3 to 4 parts of benzoyl peroxide, 33 to 36 parts of pentaerythritol triacrylate, 7 to 9 parts of isophorone diisocyanate, and 100 parts of acetic ether. The UV viscosity-reducing film has relatively high peel strength after being thermally cured, and the peel strength is greatly reduced after being irradiated by UV light; and the introduction effect of the antistatic agent is good. The adhesive-reducing film is not easy to form residual adhesive on the surface of the protected material.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

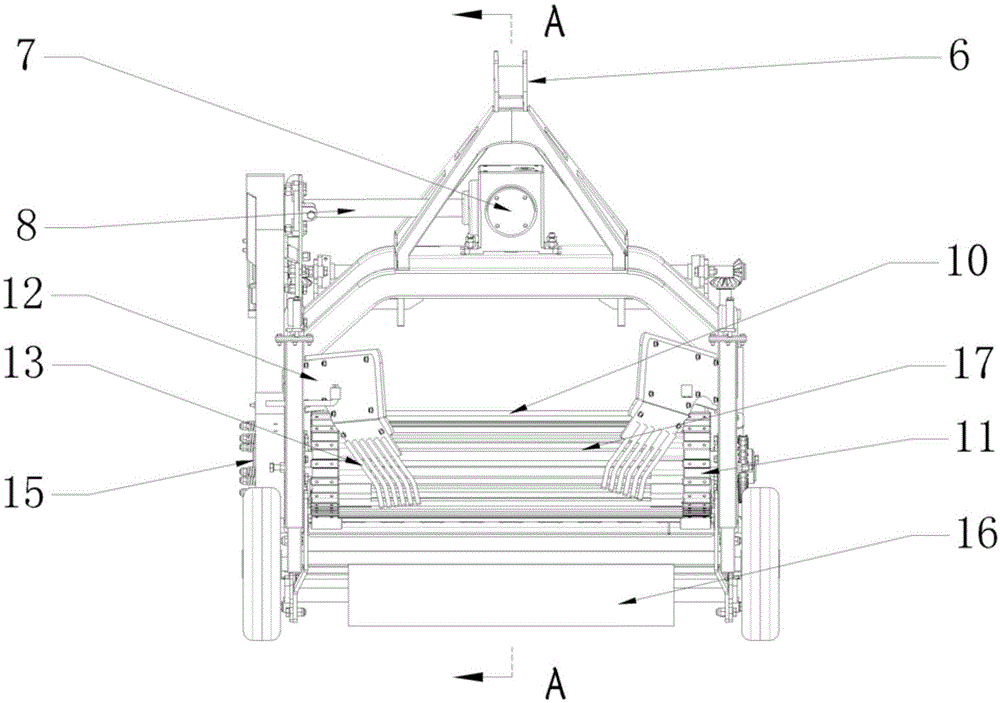

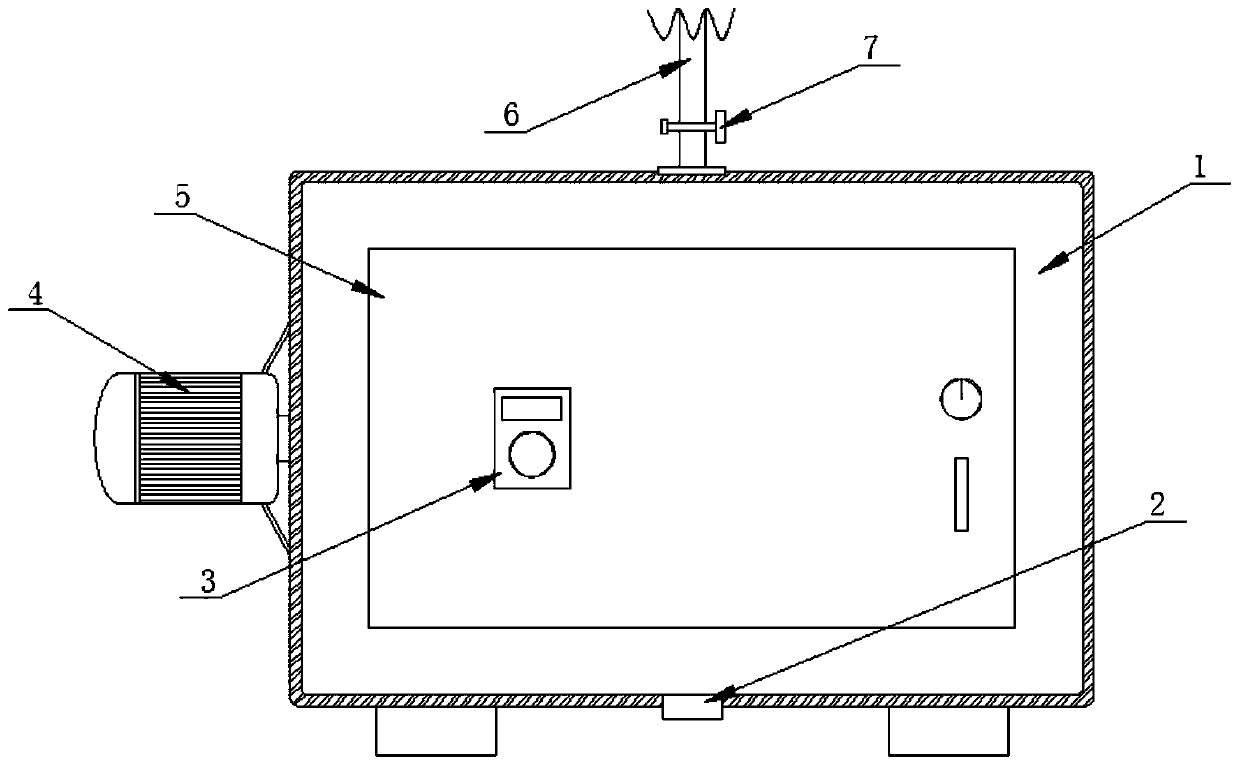

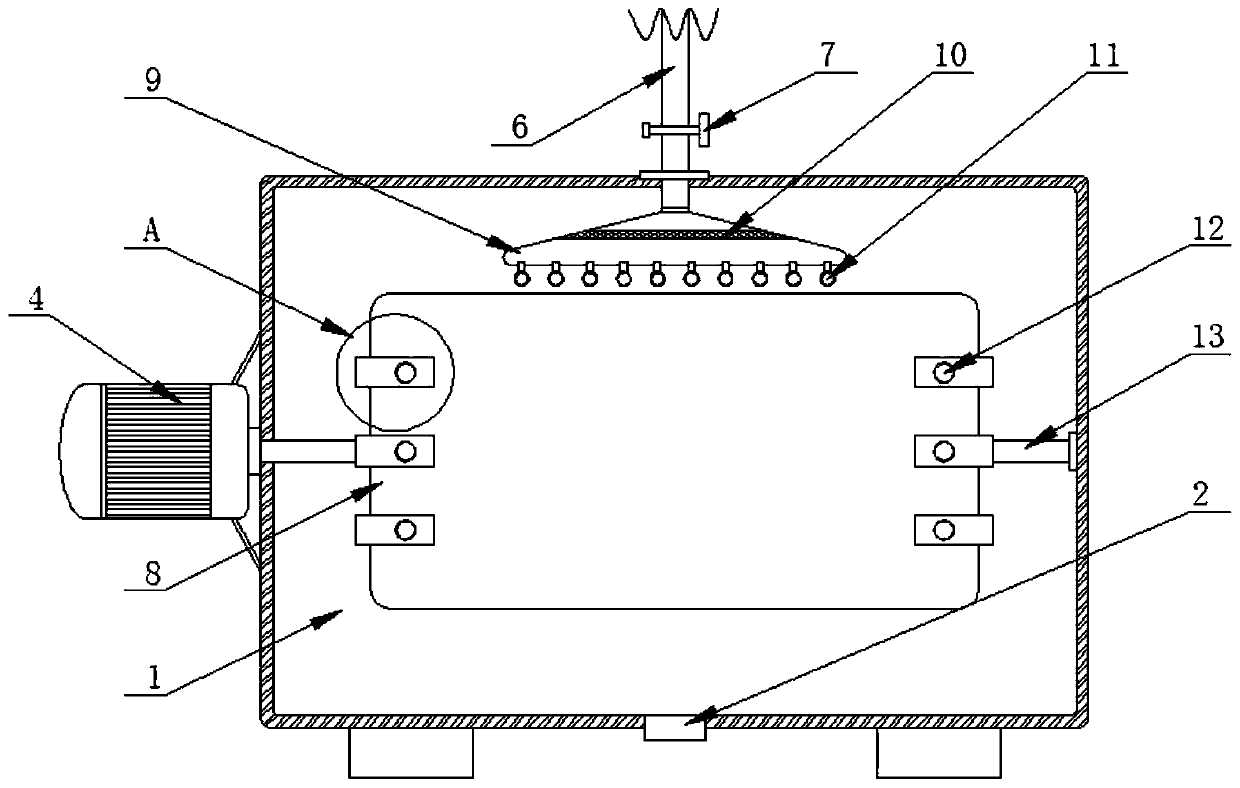

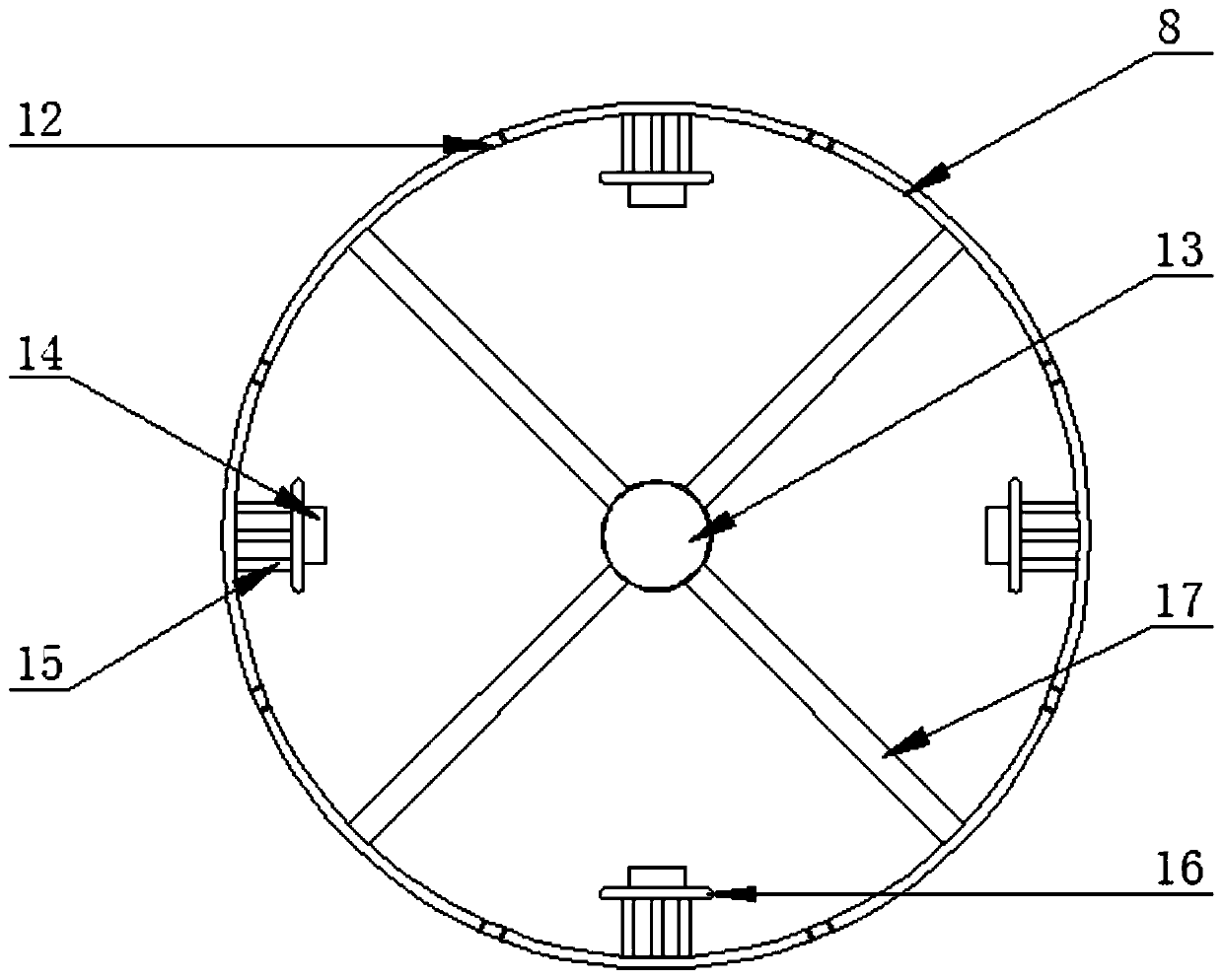

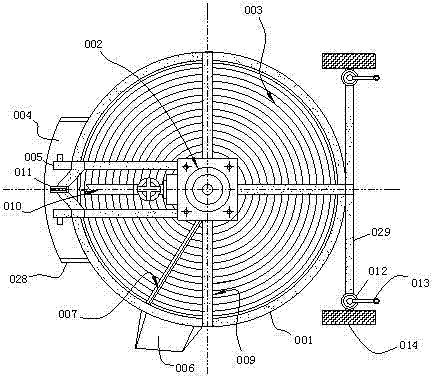

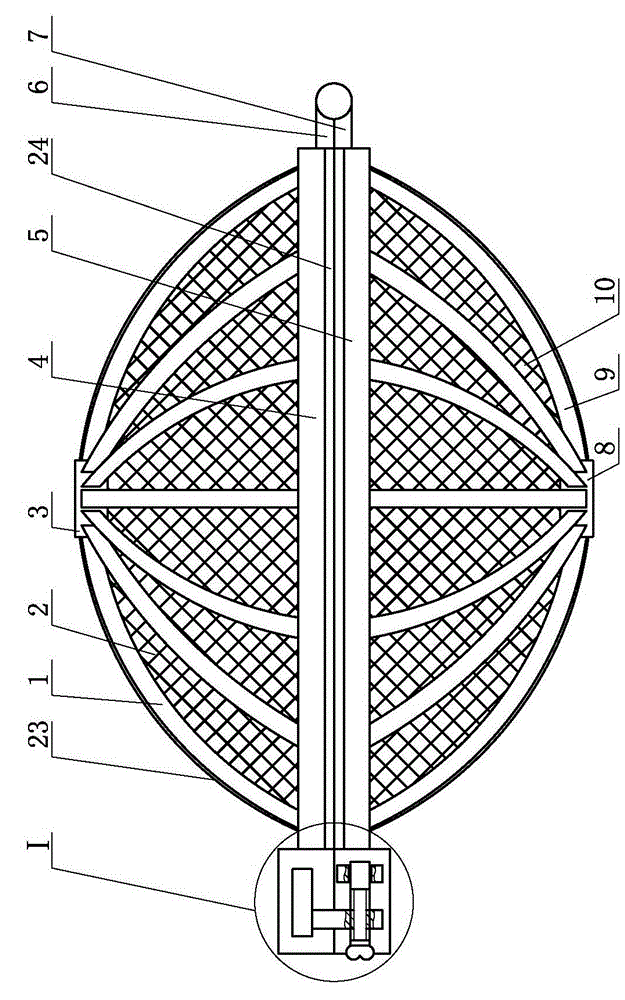

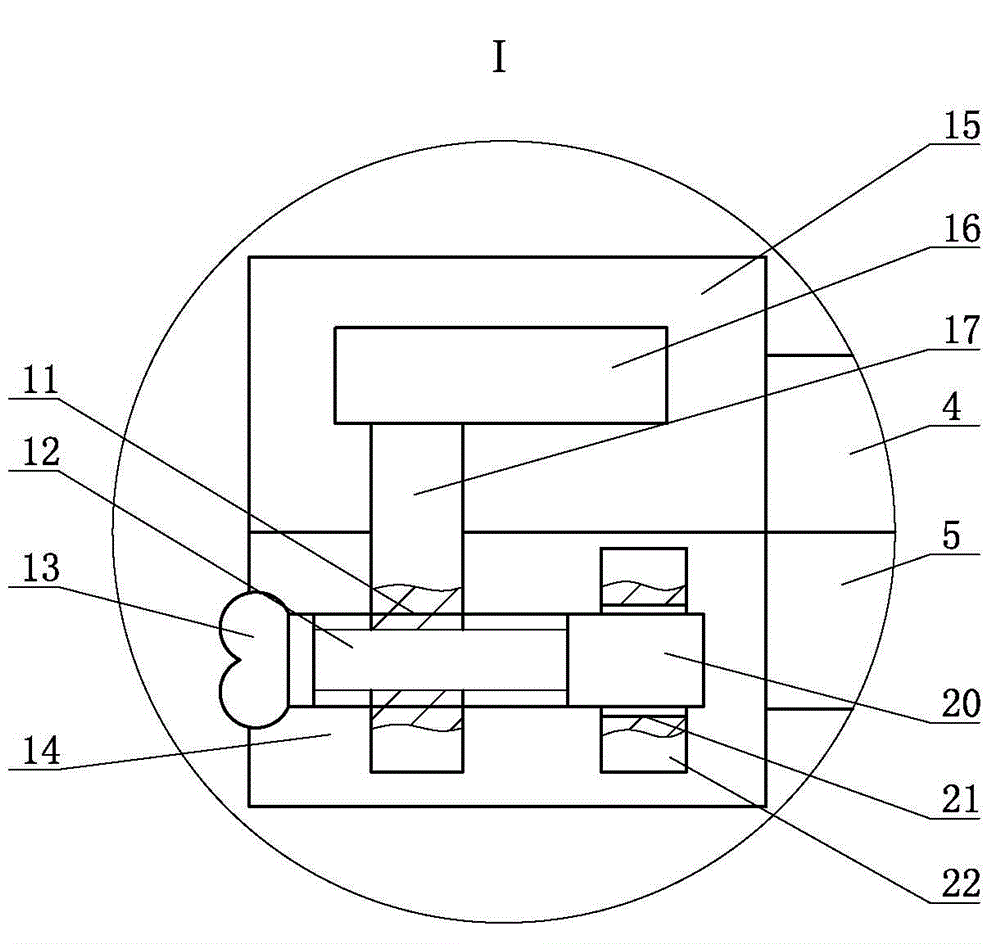

Rotary disc type tubers harvester

The invention relates to the agricultural machinery and in particular relates to a further improved multipurpose harvesting machine for tubers of crop rootstalks including potatoes, yams and the like, specifically to a rotary disc type tubers harvester. The harvester provided by the invention takes a rotary disc separating device as a body and is characterized by that: the rotary disc separating device is installed between an upper circular bracket and a lower circular bracket, an input opening and a digger shovel are distributed in front of the rotary disc separating device, the upper end ofthe input opening is connected with a suspension bracket and a dragging bracket, and the rotary disc separating device is equipped with a convex cone-shaped rotary disc mechanism or a concave cone-shaped rotary disc mechanism. The harvester provided by the invention can rapidly and completely separate soil and sieve tubers and is not easy to cause mechanical damages, prolongs the service life of the machine, is not easy to cause clay, reduces abrasion on the tubers, and has a safe use; meanwhile, the harvester has a flexible movement, can be suitable for the work of different soils, reduces construction cost, and has a light weight and the like.

Owner:戴文育

Antibacterial and antistatic fiber coating and preparation method thereof

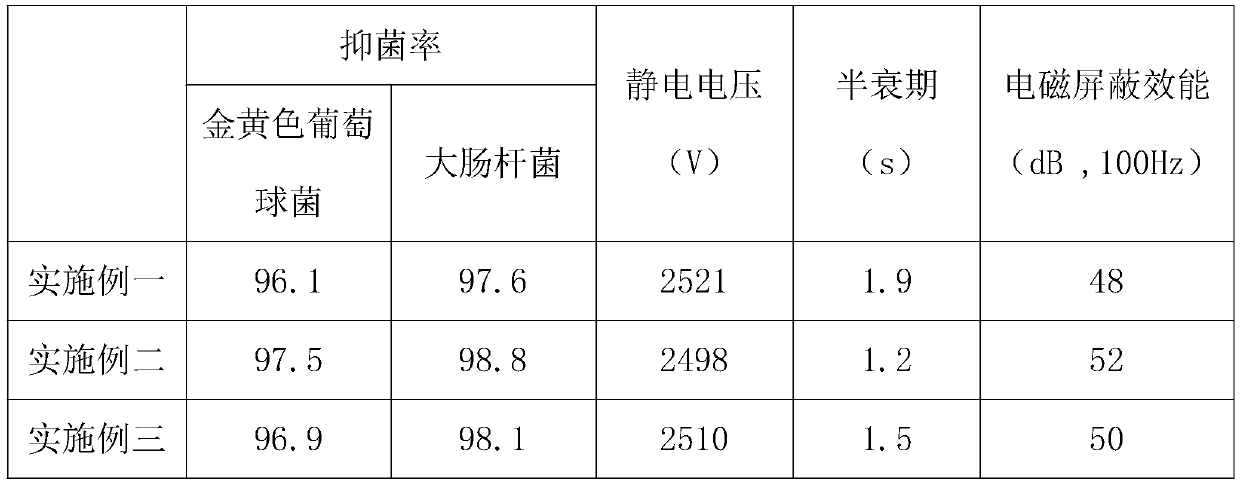

ActiveCN113699787ANucleophilicSmall sizeBiochemical fibre treatmentPolymer sciencePotassium borohydride

The invention discloses an antibacterial and antistatic fiber coating and a preparation method thereof. The preparation method comprises the following steps of firstly reacting carboxymethyl chitosan with 3-chloro-2-hydroxypropyltrimethyl ammonium chloride to prepare carboxymethyl chitosan; then reacting the carboxymethyl chitosan with potassium borohydride, adding lactose to prepare modified carboxymethyl chitosan quaternary ammonium salt, and reacting triethylene tetramine with graphene oxide to prepare modified graphene oxide; then carrying out ultrasonic treatment and mixing on the modified carboxymethyl chitosan quaternary ammonium salt and the modified graphene; and finally reacting a mixture with a resin mixed solution, and performing cooling and drying to obtain the antibacterial and antistatic fiber coating. The antibacterial and antistatic fiber coating prepared by the method has excellent antibacterial property and antistatic capability.

Owner:深圳市汇泰锦纺织有限公司

Charged foreign matter clearing unmanned aerial vehicle protection cover

The invention provides a charged foreign matter clearing unmanned aerial vehicle protection cover, which comprises a first connecting plate and a second connecting plate, wherein the end part of the first connecting plate and the end part of the second connecting plate are mutually hinged; one end of the first connecting plate is provided with a second fixing ring; the upper part of the second fixing ring is provided with an upper protection net; the upper protection net comprises a plurality of first arc-shaped rods, a copper wire layer and a first fixing ring. The first arc-shaped rods and the second arc-shaped rods are respectively made of carbon fiber, so that the first arc-shaped rods and the second arc-shaped rods can ensure the sufficient intensity of the charged foreign matter clearing unmanned aerial vehicle protection cover, and meanwhile, the weight of the charged foreign matter clearing unmanned aerial vehicle protection cover is reduced to the maximum degree. The first arc-shaped rods and the second arc-shaped rods can surround a rotor of a charged foreign matter clearing unmanned aerial vehicle for preventing foreign matters from falling on a vehicle body of the unmanned aerial vehicle and from being wound and collided with the rotor, and the influence on the normal work of the unmanned aerial vehicle is avoided.

Owner:STATE GRID CORP OF CHINA +1

A kind of healthy polyolefin foam material and preparation method thereof

The invention relates to a healthy polyolefin foam material and a preparation method thereof, which is prepared by mixing, melting and extruding, preheating and foaming the following raw and auxiliary materials in mass ratio: 70-100 parts of polyolefin resin, negative ion functional master 20-50 parts of raw material, 15-30 parts of hydrophilic functional masterbatch, 1-5 parts of foaming agent, 1-5 parts of cross-linking agent, and 0-5 parts of color masterbatch. The health-type polyolefin foam material of the present invention adds negative ion mineral materials and hydrophilic fullerene compounds into the formula, and has the advantages of air purification, surface anti-greasy, anti-static effects and the like. Utilizing the pyroelectricity and piezoelectricity of negative ion mineral materials can effectively increase the concentration of negative ions in the surrounding environment. At the same time, the hydrophilic group of the hydrophilic fullerene compound can form a hydrogen bond with water, which cuts off the connection between the pollutant and the polyolefin surface, and can also quickly leak the accumulated static charge to achieve the purpose of antistatic.

Owner:TAISHAN SPORTS IND GRP +1

External wall elastic emulsion with antistatic effect and method for preparing external wall elastic emulsion

InactiveCN108148478AThe number of hydroxyl groups increasedImprove hydrophilicityAntifouling/underwater paintsPaints with biocidesIsooctyl acrylateFunctional monomer

The invention discloses external wall elastic emulsion with an antistatic effect and a method for preparing the external wall elastic emulsion. The external wall elastic emulsion comprises, by weight,90-120 parts of deionized water, 10-30 parts of iso-octyl acrylate, 60-80 parts of butyl acrylate, 20-35 parts of styrene, 5-15 parts of methyl methacrylate, 0.1-2 parts of acrylic acid, 0.1-1.5 parts of methacrylic acid, 0.1-1 part of acrylamide, 0-0.5 part of methacrylamide, 0-0.5 part of hydroxyethyl acrylate, 3-10 parts of acrylonitrile, 0.5-3 parts of acid anhydride functional monomers, 0.5-4 parts of diethanolamine, 0.1-3 parts of modified organophosphate high polymers, 1-8 parts of emulsifiers, 0.1-5 parts of initiators and 0.3-4.5 parts of ammonia water. The external wall elastic emulsion and the method have the advantages that the antistatic effect can be realized by the external wall elastic emulsion, the external wall elastic emulsion is excellent in stain resistance, and the excellent normal-temperature and low-temperature elasticity of the external wall elastic emulsion can be kept.

Owner:上海巴德富实业有限公司

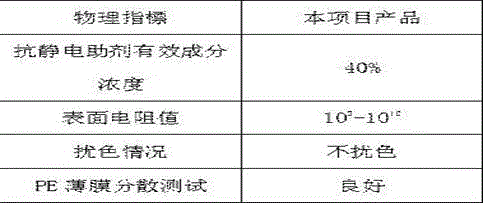

Antistatic master batch and preparation method thereof

The invention provides an antistatic master batch. The antistatic master batch comprises, by mass, 42% of polyethylene, 15% of calcium carbonate, 40% of an antistatic auxiliary agent, 2% of an anti-oxidant and 1% of a slipping agent. The invention also provides a preparation method for the antistatic master batch. The preparation method can prevent a produced polyethylene film product from the problem of static residues, enables the antistatic master batch to maintain a good dispersion and mixing degree, and allows the surface of the product to be stable, durable, antifrictional and solvent-resistant.

Owner:苏州清丰兴业塑胶有限公司

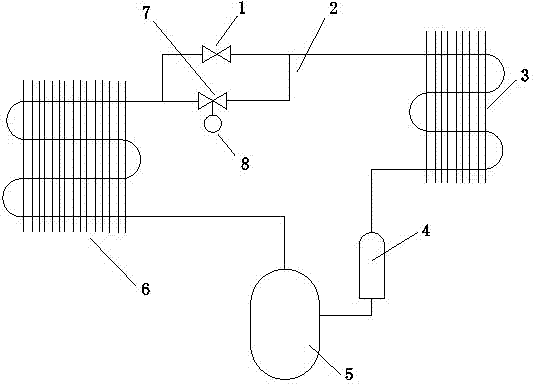

Air conditioning system with pressure relief function

InactiveCN103712382AAvoid pressure differenceImprove heat transfer effectFluid circulation arrangementRefrigeration safety arrangementRefrigerantEngineering

The invention discloses an air conditioning system with a pressure relief function. The air conditioning system comprises a compressor, a condenser, an expansion valve, an evaporator and a gas-liquid separator. A pressure relief branch is arranged between an inlet pipe of the condenser and an inlet pipe of the evaporator, an electromagnetic valve is serially connected in the pressure relief branch, and turning on and turning off of the electromagnetic valve are staggered and synchronized with turning on and turning off of the compressor. Since the pressure relief branch is arranged between the inlet pipe of the condenser and the inlet pipe of the evaporator, a high-pressure refrigerant in the condenser can be quickly released into low-pressure refrigerant of the evaporator, pressure balance of a refrigerating system is quickly established, and pressure difference is prevented from existing in the system when the compressor is started again; meanwhile, diameter of the pressure relief branch is large, so that oil return of the refrigerating system is well guaranteed, and heat exchange effect of the system is improved; moreover, a pressure sensor is further arranged at the position of the electromagnetic valve, pressure relief information can be fed back to an air conditioning control system by the pressure sensor, and accordingly convenience is brought to the control system to adjust states of an air conditioner.

Owner:ZHONGSHAN LANSHUI ENERGY TECH DEV

Double-layered garbage pyrolysis tunnel kiln

PendingCN107202491AReduce wasteUnique structureFurnace typesIncinerator apparatusTunnel kilnThermodynamics

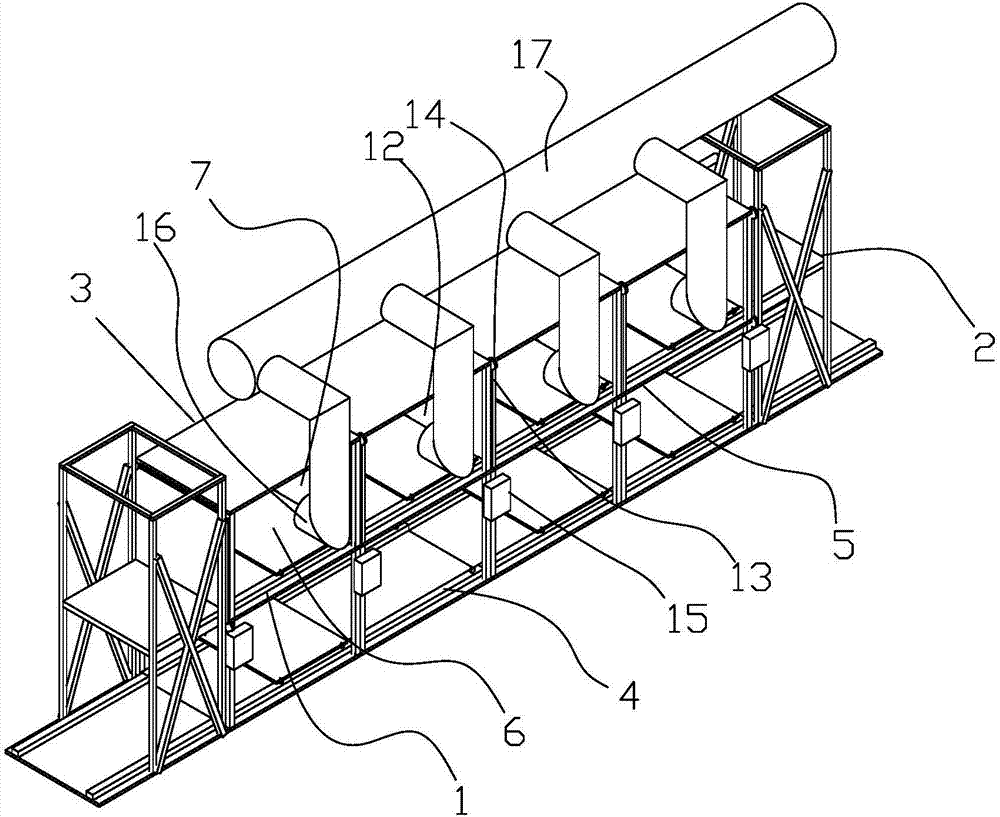

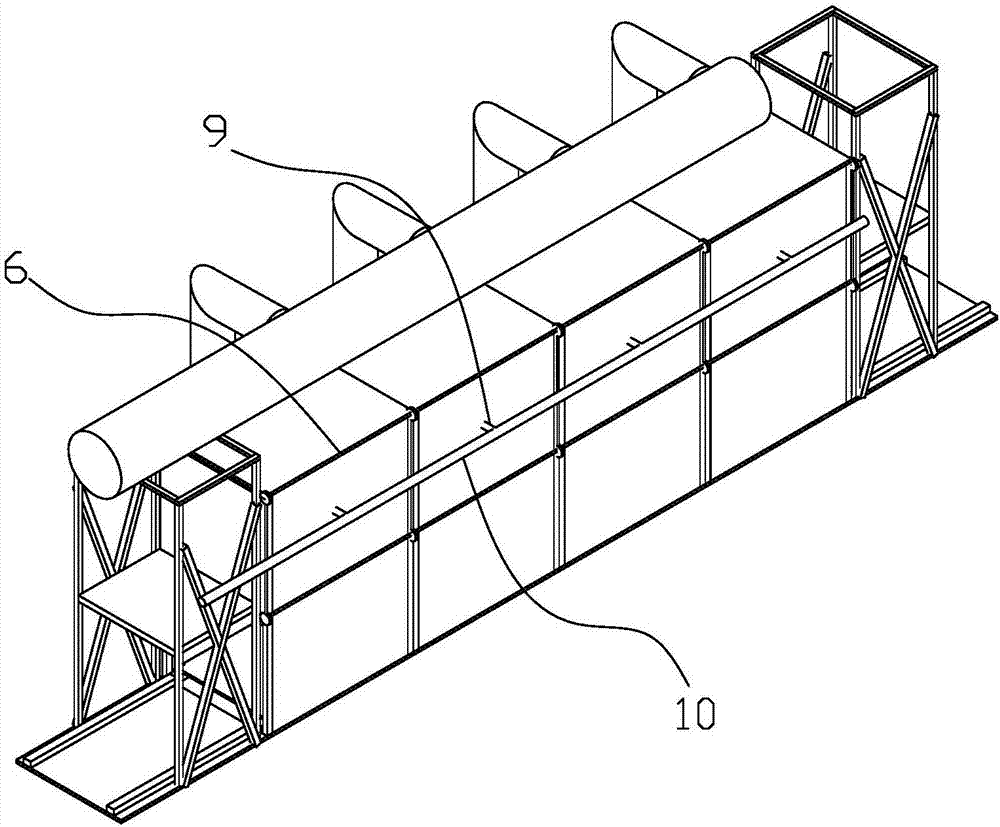

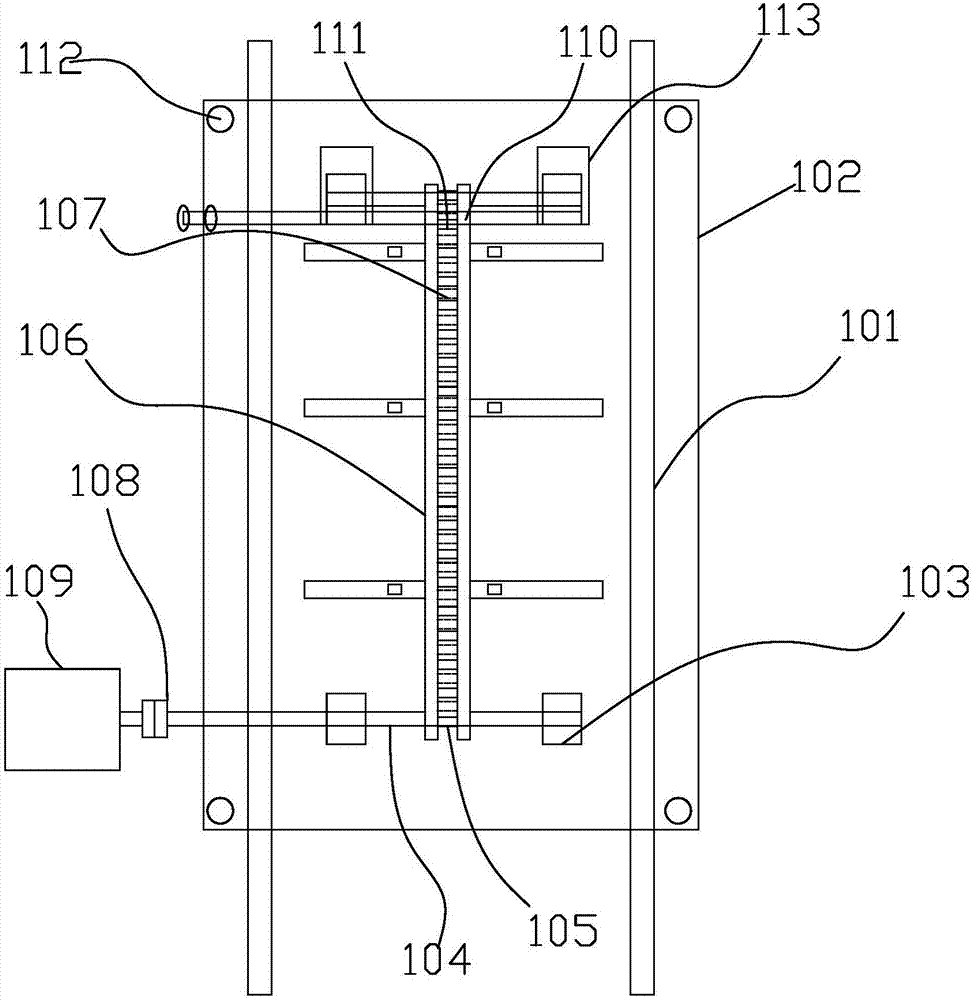

The invention discloses a double-layered garbage pyrolysis tunnel kiln. The double-layered garbage pyrolysis tunnel kiln comprises a double-layered type garbage pyrolysis tunnel kiln body (5), wherein lifting mechanisms (2) are respectively arranged at two ends of the double-layered type garbage pyrolysis tunnel kiln body (5); the double-layered type garbage pyrolysis tunnel kiln body (5) comprises an upper layer of combustion kiln body (3) and a lower layer of cooling carriage return kiln body (4); the upper layer of combustion kiln body (3) comprises a plurality of combustion kiln monomers (6) which are connected and communicated in sequence; a barrier gate (7) is arranged between one of the combustion kiln monomers and the other one of the combustion kiln monomers; the lower layer of cooling carriage return kiln body (4) comprises a plurality of cooling kiln monomers (8) which are connected and communicated in sequence; and transport vehicle transmission mechanisms (1) are both arranged in each combustion kiln monomer (6) and each cooling kiln monomer (8). The double-layered garbage pyrolysis tunnel kiln has the characteristics of high production efficiency, time saving, labor saving and energy conservation.

Owner:李观德

Method for preparing graphene short plush

PendingCN112708998ADyeing and finishing process changeHigh antibacterial rateElectroconductive/antistatic filament manufactureFibre typesTextile printerPolyester

The invention discloses a preparation method of graphene short plush, and relates to the technical field of production of preparation methods of graphene short plush. The method comprises the steps of weaving, pre-shaping, napping, printing and dyeing pretreatment, heat shaping printing or dyeing, softening finishing, ironing and shearing and finished product shaping, and is characterized in that a warp knitting machine is adopted for weaving, and DTY is obtained as surface yarns by adding 1-15% of graphene master batch into polyester chips and carrying out melt spinning, wherein medium yarns and bottom yarns are FDY obtained by adding 1-15% of graphene master batch into polyester chips and performing melt spinning. By adopting the production process provided by the invention, natural antibacterial, anti-mite, anti-static, far-infrared and ultraviolet functions and the like can be achieved. Therefore, the environment-friendly graphene short plush is developed.

Owner:张敏洁

High-speed antistatic spinning rubber roller

InactiveCN111057459AGuaranteed high speed operationHigh hardnessPolyurea/polyurethane coatingsElectrically-conductive paintsPolymer scienceSpinning

The invention discloses a high-speed antistatic spinning rubber roller. The roller is characterized in that the roller comprises a roller core and a polyurethane rubber coating layer wrapping the roller core, and the polyurethane rubber coating layer is a coating layer which is prepared from an antistatic polyurethane coating synthesized from polymer polyether polyol (POP), 4,4-diphenylmethane diisocyanate and a conductive substance and has good hardness, elasticity, antistatic property, wear resistance and heat resistance. According to the spinning rubber roller, through experimental detection, compared with an existing rubber roller, the spinning rubber roller has the advantages that the hardness, elasticity, antistatic property, wear resistance and heat resistance of the spinning rubberroller are remarkably improved, the service life of the spinning rubber roller can be remarkably prolonged, and the spinning quality and efficiency of spinning machinery can be remarkably improved.

Owner:JIANGSU YIREN CHEM FIBER TEXTILE CO LTD

Antistatic polyester fabric and processing process thereof

The invention relates to antistatic polyester fabric. The antistatic polyester fabric consists of ground cloth filaments and plush. The fabric is characterized in that the ground cloth filaments are woven from nylon carbon filaments and polyester filaments, wherein the nylon carbon filaments are 20-30 D and the polyester filaments are 70-80 D. The advantages of the antistatic polyester fabric arethat conductive filaments formed by combining the nylon carbon filaments and the common polyester filaments are added into the structure of the polyester fabric by weaving so as to improve the antistatic property of the polyester fabric and enables the polyester fabric to quickly leak electrostatic charge of the fabric.

Owner:QINGDAO JISHENG TEXTILE CO LTD

Anti-static fabric for pregnant women and preparation method thereof

InactiveCN111376556ASoft and comfortableGood hygroscopicityCarbon fibresBiochemical fibre treatmentPolyesterPolymer science

The invention relates to the technical field of fabrics, and provides an anti-static fabric for pregnant women and a preparation method thereof. The problems that in the prior art, fabric is poor in antistatic property, and static electricity is easy to accumulate to cause harm can be solved. The anti-static fabric comprises a base fabric layer, wherein a surface layer is arranged on the base fabric layer; wherein an anti-radiation layer is arranged between the base fabric layer and the surface layer; wherein the base fabric layer is formed by interweaving first warp yarns and first weft yarns; the surface layer is formed by interweaving second warp yarns and second weft yarns; the first warp yarns are copper ammonia / cotton blended yarns; the first weft yarns are polylactic acid / cotton blended yarns; wherein the first warp yarns are chitin / polyester blended yarns, the second weft yarns are modal / bamboo charcoal fibers, the anti-radiation layer raw materials are uniformly mixed and thencoated on the base fabric layer, then the surface layer is bonded on the anti-radiation layer through an adhesive, and finally the fabric is soaked in an anti-static finishing liquid and dried to obtain the anti-static fabric for pregnant women.

Owner:诸暨市孕创互联服饰有限公司

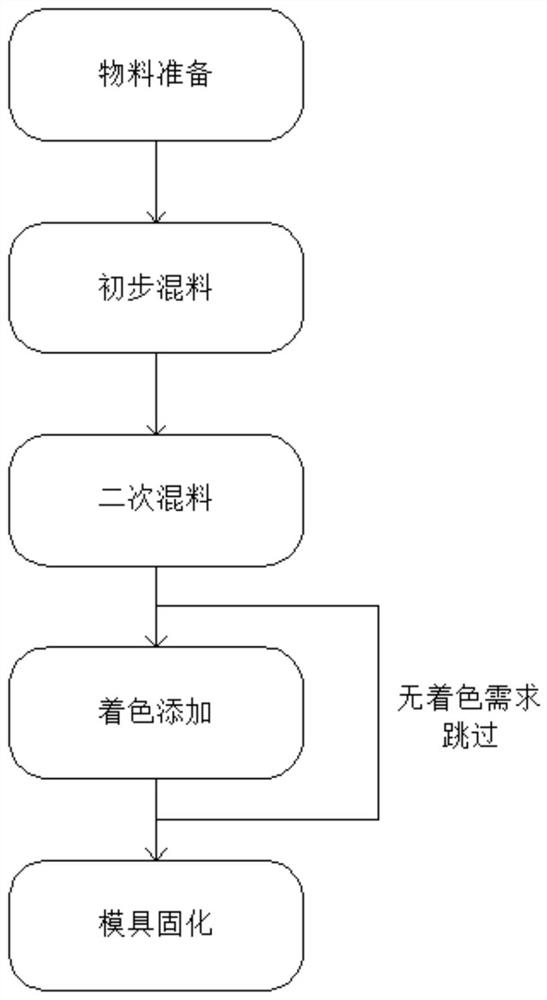

Formula and preparation method of infant grade silica gel

PendingCN114015239AImprove antibacterial propertiesImprove antistatic performanceFood gradeCross linker

The invention provides a formula and a preparation method of infant grade silica gel. The infant grade silica gel comprises the following raw materials in parts by weight: 70-90 parts of a component A raw material, 70-90 parts of a component B raw material, 0.05-0.1 part of a vulcanizing agent, 5-10 parts of a cross-linking agent, 5-10 parts of white carbon black, 3-5 parts of a food grade coloring agent, 5-9 parts of an antibacterial additive, 5-10 parts of silica powder and 3-5 parts of an antistatic agent. The liquid silica gel is prepared by adopting the two-component silica gel as a raw material, the process is simple, operation is rapid, the antibacterial additive is introduced to improve the antibacterial performance of the silica gel, then the silica powder is introduced to form a conductive layer on the surface of the liquid silica gel, so that the surface resistivity is reduced, and then the silica powder is matched with the antistatic agent to improve the anti-static performance of theliquid silica gel, so that the silica gel is adapted to infants; in addition, in the preparation process of the silica gel, a gradual heating mode is adopted to ensure the uniformity of vulcanization.

Owner:SHENZHEN YUAN FENG XING YE TECH CO LTD

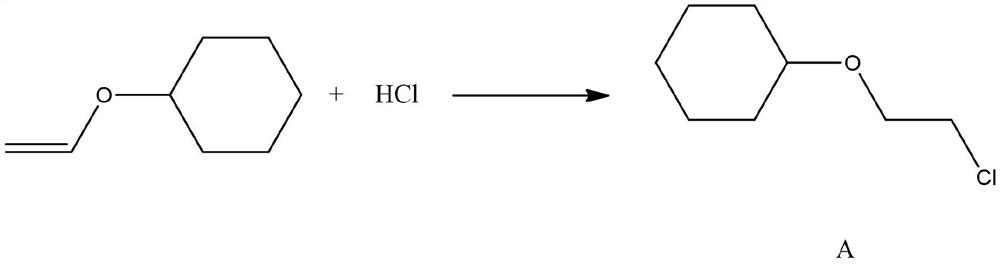

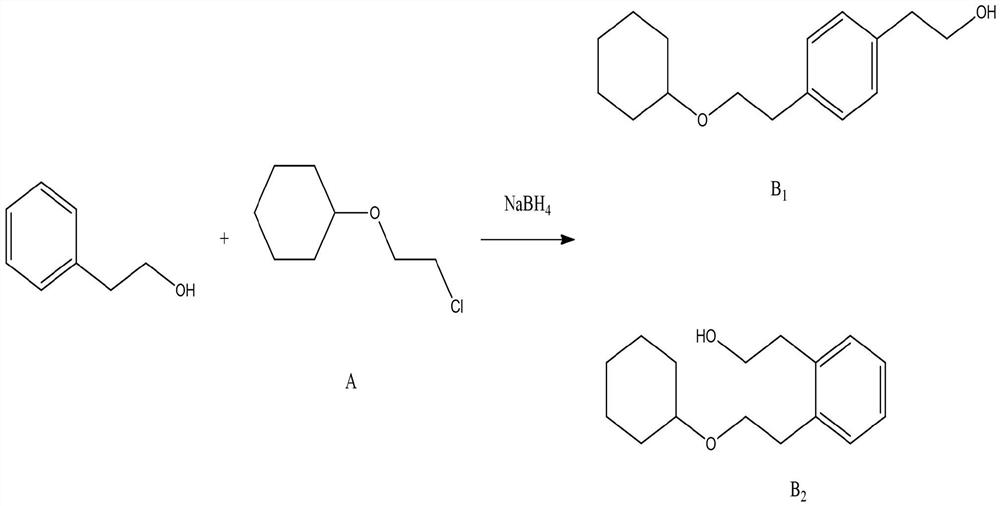

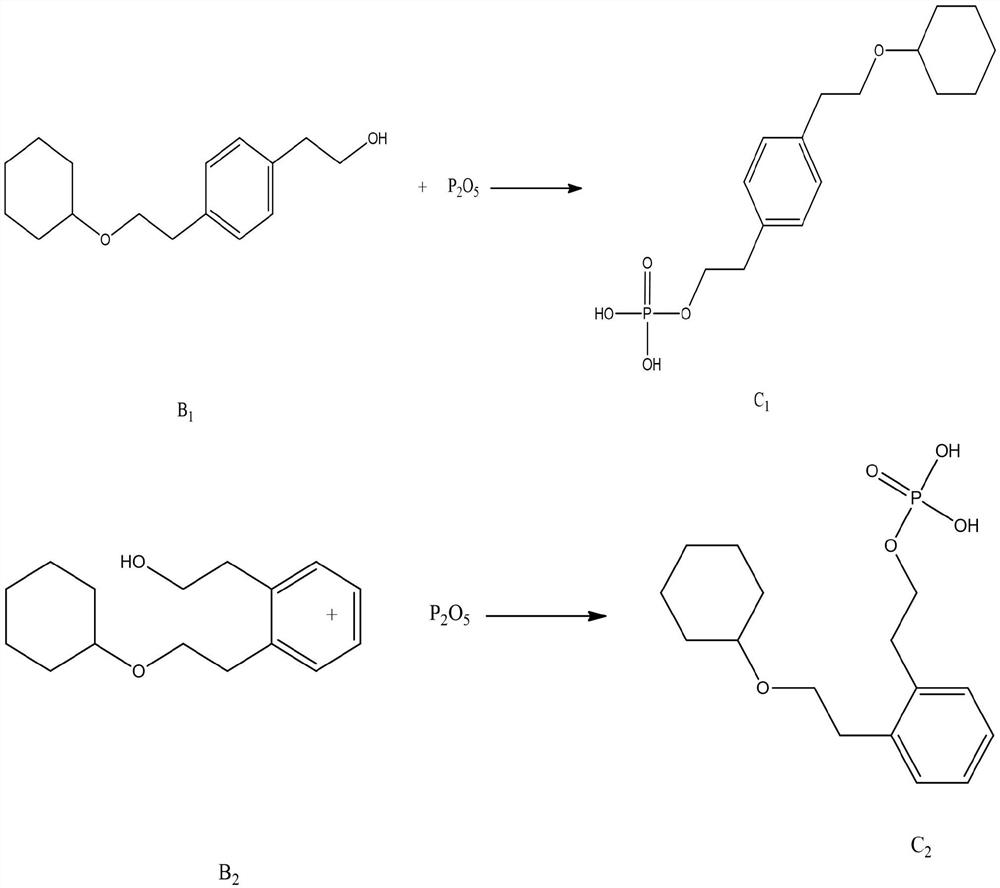

Production process of anti-static suit fabric

PendingCN113265738ASolve the problem of thick, no three-dimensional effect, and affect the aesthetic feelingReduce hydrophilicityFibre treatmentMulti-ply fabricsPhosphoric Acid EstersYarn

The invention discloses a production process of an anti-static suit fabric. The production process comprises the following steps that an outer-layer fabric is treated by using an alkali-oxygen cold pad-batch process; then the outer-layer fabric is pre-shaped, and dyeing pretreatment is carried out on the outer-layer fabric; then padding the dried fabric is sequentially padded in a fatty acid methyl ester ethoxylate sodium sulfonate solution, a reactive dye solution and an anti-static treatment solution, and color fixation, water washing, soaping, drying and soaping are carried out; and the outer-layer fabric and the inner-layer fabric are bound and fixed by adopting binding warp yarns. The problems that the suit is thick and heavy, has no stereoscopic impression and affects the aesthetic feeling are solved; by adding the anti-static liquid, phosphate ester salt groups in the anti-static liquid and hydrogen bonds of water molecules in the air act on the fiber surface to form a conductive layer, so that the surface resistivity is reduced, and the generated static charges are quickly leaked, so that the anti-static property of the suit fabric is improved.

Owner:安徽弋尚纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com