Production process of anti-static suit fabric

A production process, anti-static technology, applied in clothing, clothing, protective clothing, etc., can solve the problem that static electricity cannot play a protective role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Present embodiment is a kind of antistatic suit fabric, and the preparation process of antistatic suit fabric is as follows:

[0035] S1: Select the outer fabric, process the outer fabric with alkali-oxygen cold pad-batch process, then pre-set the outer fabric, pre-dye the outer fabric, and then pad the dried fabric with fatty acid formazan Ester ethoxylate sodium sulfonate solution, reactive dye solution, anti-static treatment solution, color fixation, water washing, soaping, drying, the liquid carrying rate after padding is 80%, and then soaping;

[0036] Wherein the preparation method of antistatic liquid is as follows:

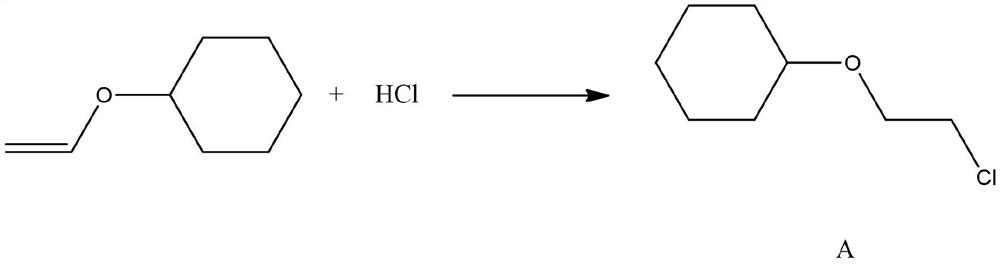

[0037] S21: adding vinyl cyclohexyl ether into a closed Erlenmeyer flask containing hydrogen chloride and capping the bottle stopper, and after reacting for 2 hours, intermediate A was obtained;

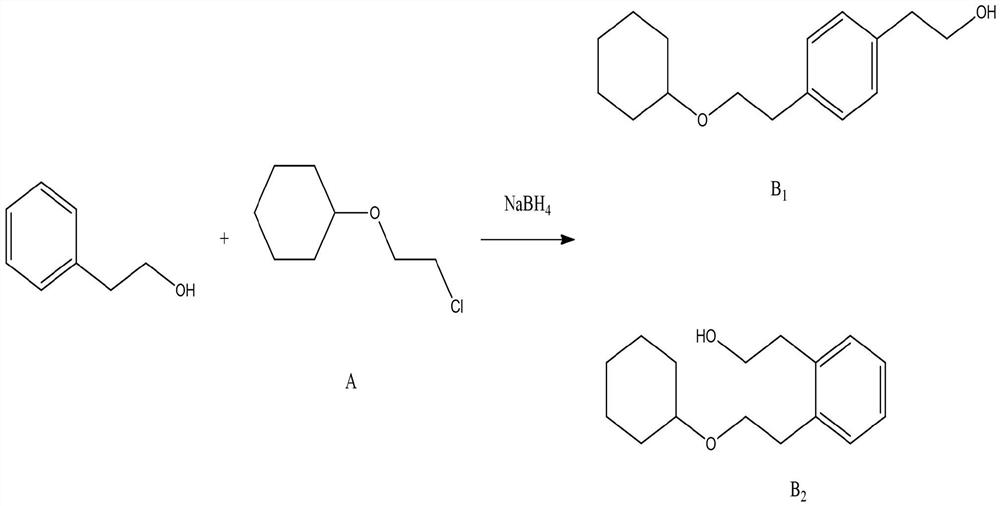

[0038] S22: Add phenylethanol to intermediate A, add NaBH 4 As a catalyst, after reacting for 6h, intermediate B was obtained;

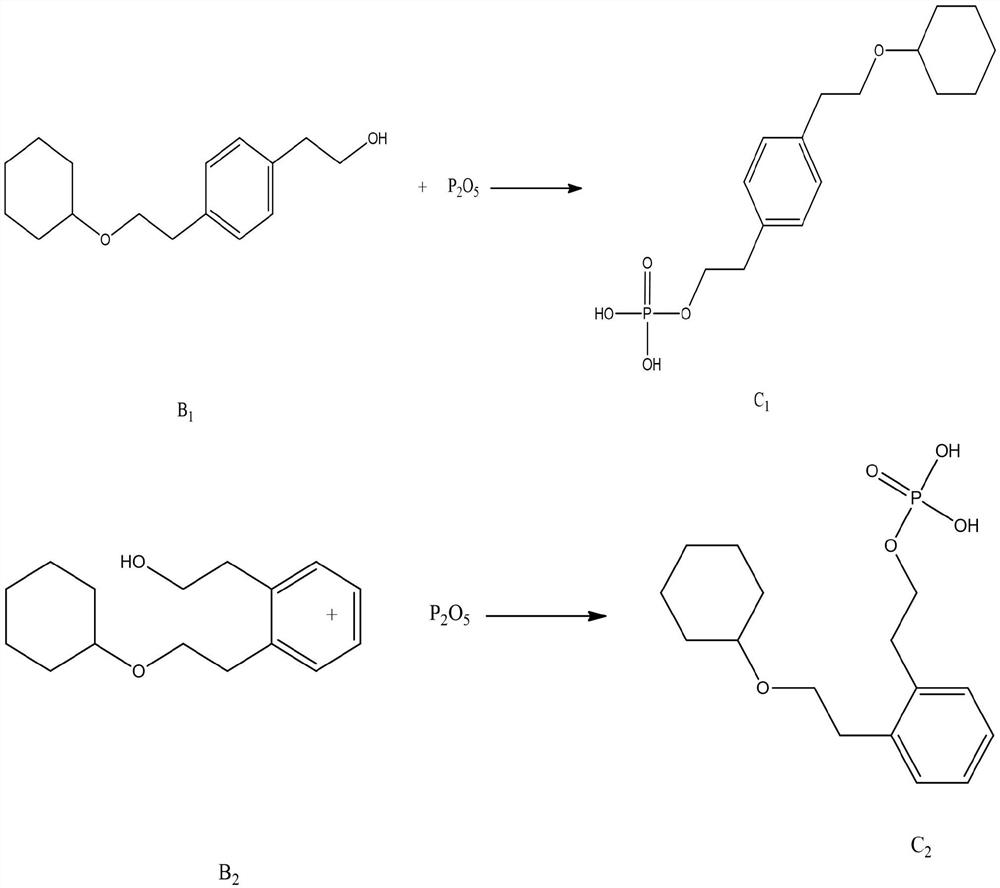

[0039] S23: Add phosph...

Embodiment 2

[0044] Present embodiment is a kind of antistatic suit fabric, and the preparation process of antistatic suit fabric is as follows:

[0045] S1: Select the outer fabric, process the outer fabric with alkali-oxygen cold pad-batch process, then pre-set the outer fabric, pre-dye the outer fabric, and then pad the dried fabric with fatty acid formazan Ester ethoxylate sodium sulfonate solution, reactive dye solution, anti-static treatment solution, color fixation, water washing, soaping, drying, the liquid carrying rate after padding is 70%, and then soaping;

[0046] Wherein the preparation method of antistatic liquid is as follows:

[0047] S21: adding vinyl cyclohexyl ether into a closed Erlenmeyer flask containing hydrogen chloride and capping the bottle stopper, and after reacting for 2 hours, intermediate A was obtained;

[0048] S22: Add phenylethanol to intermediate A, add NaBH 4 As a catalyst, after reacting for 8 hours, intermediate B was obtained;

[0049] S23: Add p...

Embodiment 3

[0054] Present embodiment is a kind of antistatic suit fabric, and the preparation process of antistatic suit fabric is as follows:

[0055] S1: Select the outer fabric, process the outer fabric with alkali-oxygen cold pad-batch process, then pre-set the outer fabric, pre-dye the outer fabric, and then pad the dried fabric with fatty acid formazan Ester ethoxylate sodium sulfonate solution, reactive dye solution, anti-static treatment solution, color fixation, water washing, soaping, drying, the liquid carrying rate after padding is 70%, and then soaping;

[0056] Wherein the preparation method of antistatic liquid is as follows:

[0057] S21: adding vinyl cyclohexyl ether into a closed Erlenmeyer flask containing hydrogen chloride and capping the bottle stopper, and after reacting for 1 hour, intermediate A was obtained;

[0058] S22: Add phenylethanol to intermediate A, add NaBH 4 As a catalyst, after reacting for 5h, intermediate B was obtained;

[0059] S23: Add phospho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com