Antistatic organic-silicon synthetic leather and preparation method thereof

An organosilicon synthetic leather and antistatic technology, applied in the field of synthetic leather, can solve the problems of easy to produce environmental hazards, easy accumulation of static electricity and dust, and achieve the effect of reducing dust adsorption and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

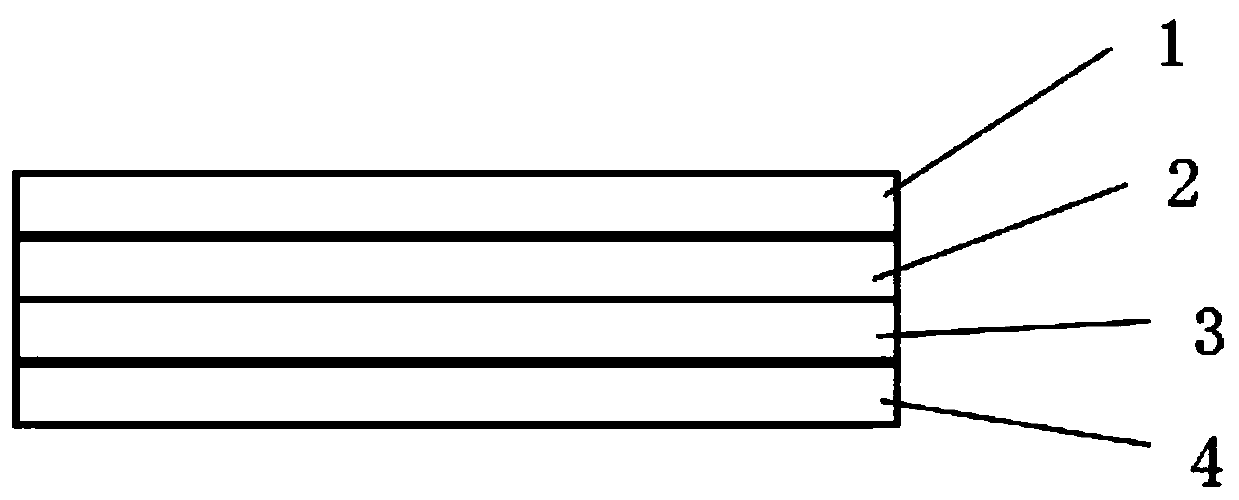

[0035] A kind of antistatic organic silicon synthetic leather, described synthetic leather is surface layer, surface layer, bottom layer and substrate layer successively from top to bottom, and described surface layer is acrylamide hydrogel, and described surface layer comprises the following weight ratio Components: 35 parts of vinyl silicone resin, 25 parts of methyl vinyl silicone oil, 8 parts of crosslinking agent, 0.4 part of platinum catalyst, 0.1 part of inhibitor, 10 parts of filler, 0 part of color paste, the bottom layer includes the following weight formula Ratio of components: 70 parts of base glue, 8 parts of vinyl silicone resin, 0.4 parts of platinum catalyst, 0.1 part of inhibitor, 10 parts of crosslinking agent, 10 parts of filler, 5 parts of color paste; the antistatic organic silicon synthetic leather The preparation includes the following steps:

[0036] 1. Preparation of synthetic leather

[0037] Prepare the surface layer raw materials in proportion, coa...

Embodiment 2

[0044] A kind of antistatic organic silicon synthetic leather, described synthetic leather is surface layer, surface layer, bottom layer and substrate layer successively from top to bottom, and described surface layer is acrylamide hydrogel, and described surface layer comprises the following weight ratio Components: 15-65 (3565) parts of vinyl silicone resin, 10 parts of methyl vinyl silicone oil, 18 parts of crosslinking agent, 1.0 parts of platinum catalyst, 0.4 parts of inhibitor, 25 parts of filler, 5 parts of color paste, the The bottom layer includes the following components by weight: 40 parts of base rubber, 18 parts of vinyl silicone resin, 1.0 parts of platinum catalyst, 0.4 parts of inhibitor, 12 parts of crosslinking agent, and 25 parts of filler; the antistatic organic silicon synthetic leather The preparation includes the following steps:

[0045] 1. Preparation of synthetic leather

[0046] Prepare the surface layer raw materials in proportion, coat them on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com