Formula and preparation method of infant grade silica gel

A technology for infants and young children, silica gel, applied in the formulation and preparation of infant-grade silica gel, can solve the problem that silica gel is not suitable for infants and young children, and achieves the effect of ensuring uniformity, improving antibacterial properties, and improving antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

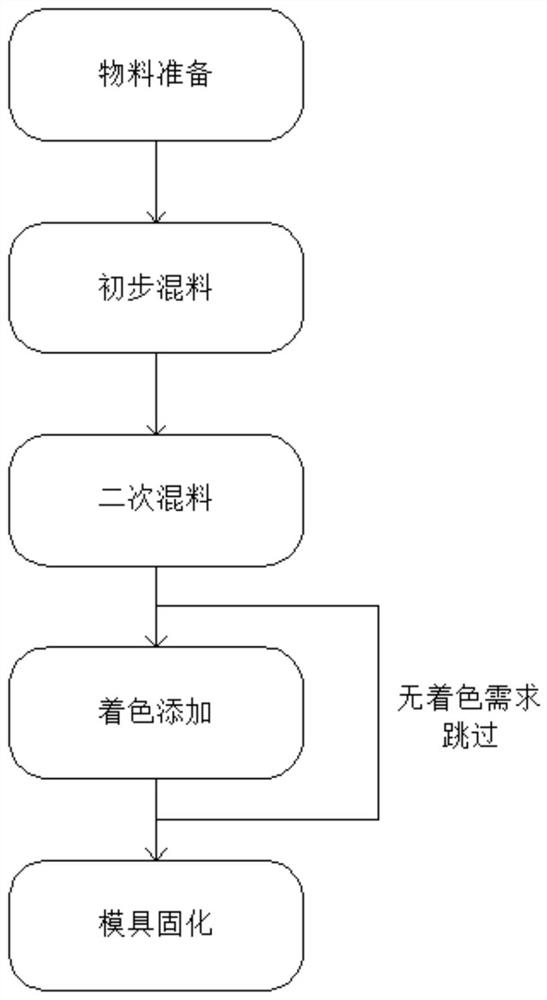

[0030] according to figure 1 , this embodiment proposes a formula of infant grade silica gel, a formula of infant grade silica gel and its preparation method, including the following raw materials by weight: 70-90 parts of raw materials for component A, 70-90 parts of raw materials for component B 0.05-0.1 parts of vulcanizing agent, 5-10 parts of cross-linking agent, 5-10 parts of white carbon black, 3-5 parts of food grade colorant, 5-9 parts of antibacterial additive, 5-10 parts of silicon micropowder and antistatic 3 to 5 doses.

[0031] Including the following raw materials by weight: 80 parts of raw materials for component A, 80 parts of raw materials for component B, 0.07 parts of platinum catalyst, 8 parts of crosslinking agent, 8 parts of white carbon black, 4 parts of food grade colorant, 7 parts of antibacterial additive, silicon 8 parts of micro powder and 4 parts of antistatic agent.

[0032] The vulcanizing agent is a platinum catalyst, and the platinum catalys...

Embodiment 2

[0049] according to figure 1 , this embodiment proposes a formula for infant grade silica gel, including the following raw materials by weight: 90 parts of raw materials for component A, 90 parts of raw materials for component B, 0.1 parts of platinum catalyst, 10 parts of crosslinking agent, and 10 parts of white carbon black 5 parts, 5 parts of food-grade colorant, 9 parts of antibacterial additive, 10 parts of silicon micropowder and 5 parts of antistatic agent.

[0050] The vulcanizing agent is a platinum catalyst, and the platinum catalyst itself is a platinum catalyst with high activity and high catalytic efficiency, without side reactions, and has the advantages of good stability and strong toxicity resistance. During the process, do not encounter sulfides, nitrides, phosphides, organic metals, etc., which will cause poisoning of the platinum catalyst and will not cause a sulfidation reaction. When this happens, the platinum catalyst needs to be regenerated.

[0051] T...

Embodiment 3

[0067] This example proposes a formula for infant grade silica gel, including the following raw materials by weight: 70 parts of raw materials for component A, 70 parts of raw materials for component B, 0.05 parts of platinum catalyst, 5 parts of crosslinking agent, and 5 parts of white carbon black , 5 parts of antibacterial additives, 5 parts of silicon micropowder and 3 parts of antistatic agent.

[0068] The vulcanizing agent is a platinum catalyst, and the platinum catalyst itself is a platinum catalyst with high activity and high catalytic efficiency, without side reactions, and has the advantages of good stability and strong toxicity resistance. During the process, do not encounter sulfides, nitrides, phosphides, organic metals, etc., which will cause poisoning of the platinum catalyst and will not cause a sulfidation reaction. When this happens, the platinum catalyst needs to be regenerated.

[0069] The crosslinking agent is polymethylhydrogensiloxane.

[0070] Descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com