UV viscosity-reducing adhesive with antistatic effect and preparation method of viscosity-reducing adhesive

An antistatic and antistatic agent technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problem of no antistatic effect and limited application range of viscosifying adhesives, and achieve good adhesion and interface bonding performance, improving cohesive strength and interface bonding strength, and avoiding the effect of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of the UV viscosity-reducing adhesive with antistatic effect, comprises the following steps:

[0035] 1) Synthesis of dual-curable polyurethane acrylate pressure-sensitive adhesive: according to the above-mentioned raw material formula of UV viscosifying adhesive with antistatic effect, respectively weigh n-butyl acrylate, 2-ethylhexyl acrylate, and hydroxyethyl acrylate , acrylic acid, and benzoyl peroxide were added to a four-neck flask, mixed evenly with 50 parts of ethyl acetate, and randomly copolymerized by free radical polymerization to obtain a polyacrylate prepolymer. Then, add pentaerythritol triacrylate, isophorone diisocyanate, and 50 parts of ethyl acetate in the four-necked flask, and continue the addition polymerization reaction to prepare a dual-curable polyurethane acrylic pressure-sensitive adhesive;

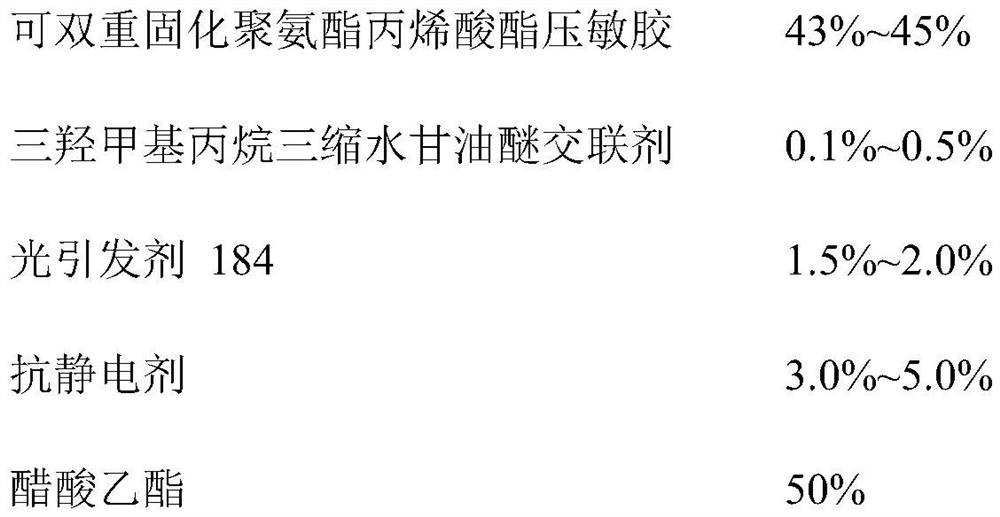

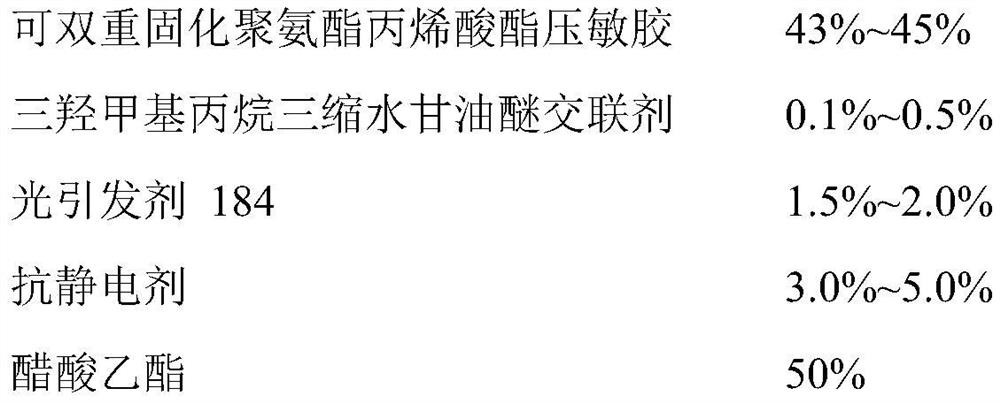

[0036] 2) Preparation of UV viscosifying adhesive with antistatic effect: according to the above-mentioned raw material for...

Embodiment 1

[0042] 1) Preparation of dual-curable polyurethane acrylate pressure-sensitive adhesive:

[0043] Using the following components by mass as raw materials, a dual-curable polyurethane acrylate pressure-sensitive adhesive is prepared by free radical polymerization and addition polymerization:

[0044] 16 parts of n-butyl acrylate

[0045] 23 parts of 2-ethylhexyl acrylate

[0046] 8 parts of hydroxyethyl acrylate

[0047] Acrylic 5 parts

[0048] 4 parts benzoyl peroxide

[0049] 35 parts of pentaerythritol triacrylate

[0050] 9 parts of isophorone diisocyanate

[0051] 100 parts of ethyl acetate

[0052] The free radical polymerization reaction temperature is controlled at 80-85°C, the constant pressure funnel is added for 1.5 hours, and the reflux reaction is 2.5 hours; the addition polymerization reaction temperature is controlled at 80±3°C, the reflux reaction is 2.5 hours, and the temperature is lowered. Dual cure urethane acrylate pressure sensitive adhesive.

[0...

Embodiment 2

[0066] 1) Preparation of dual-curable polyurethane acrylate pressure-sensitive adhesive:

[0067] Using the following components by mass as raw materials, a dual-curable polyurethane acrylate pressure-sensitive adhesive is prepared by free radical polymerization and addition polymerization:

[0068] 20 parts of n-butyl acrylate

[0069] 21 parts of 2-ethylhexyl acrylate

[0070] 10 parts of hydroxyethyl acrylate

[0071] 4 parts acrylic

[0072] 3 parts benzoyl peroxide

[0073] 33 parts of pentaerythritol triacrylate

[0074] 9 parts of isophorone diisocyanate

[0075] 100 parts of ethyl acetate

[0076] The free radical polymerization reaction temperature is controlled at 80-85°C, the constant pressure funnel is added for 1.5 hours, and the reflux reaction is 2.5 hours; the addition polymerization reaction temperature is controlled at 80±3°C, the reflux reaction is 2.5 hours, and the temperature is lowered. Dual cure urethane acrylate pressure sensitive adhesive.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 180°peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com