Rotary disc type tubers harvester

A harvester and turntable technology, which is applied in digging harvesters, harvesters, excavators, etc., can solve the problems of easy wear of metal rods, short service life, and high cost of use, so that it is not easy to be mechanically damaged, reduces wear, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

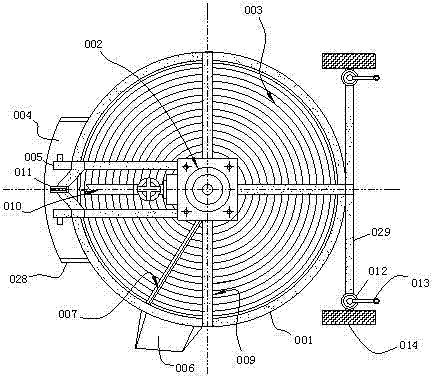

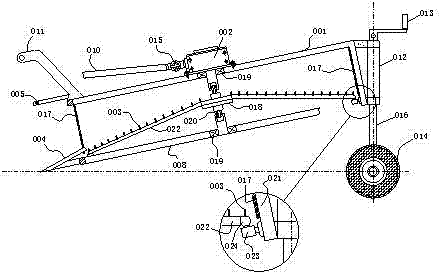

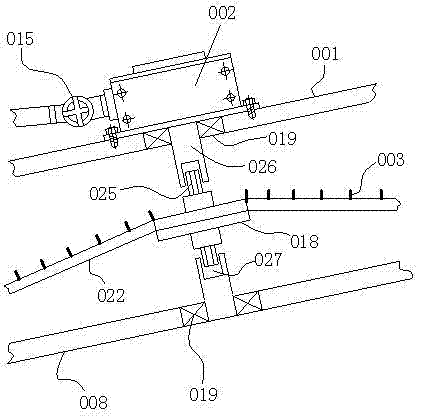

[0027] Attached below Figure 1-7 The present invention is further described.

[0028] Schematic diagram of the device according to the first embodiment of the present invention figure 1Among them, the harvester is mainly based on the rotary disc separation device, and is characterized in that: the upper circle support 001 and the lower circle support 008 are connected through several support frames 021 and the outer circle guard plate 017 is arranged, and the upper circle support 001 and the lower circle support 001 are connected to each other. The middle position of the circle bracket 008 is selected to place a convex cone turntable mechanism, the outer circle guard plate 017 is fixed on the support frame 021, an input port is located in front of the lower circle bracket 008, and an excavating shovel 004 is installed in front of the input port , the two sides of digging shovel 004 are respectively placed a dividing soil board 028, and the upper end position of input port is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com