Double-layered garbage pyrolysis tunnel kiln

A technology of tunnel kiln and pyrolysis, applied in lighting and heating equipment, combustion methods, furnace types, etc., can solve the problems of low work efficiency, inability to extract raw materials, energy waste, etc., and achieve high work efficiency, good sealing performance, The effect of rational use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

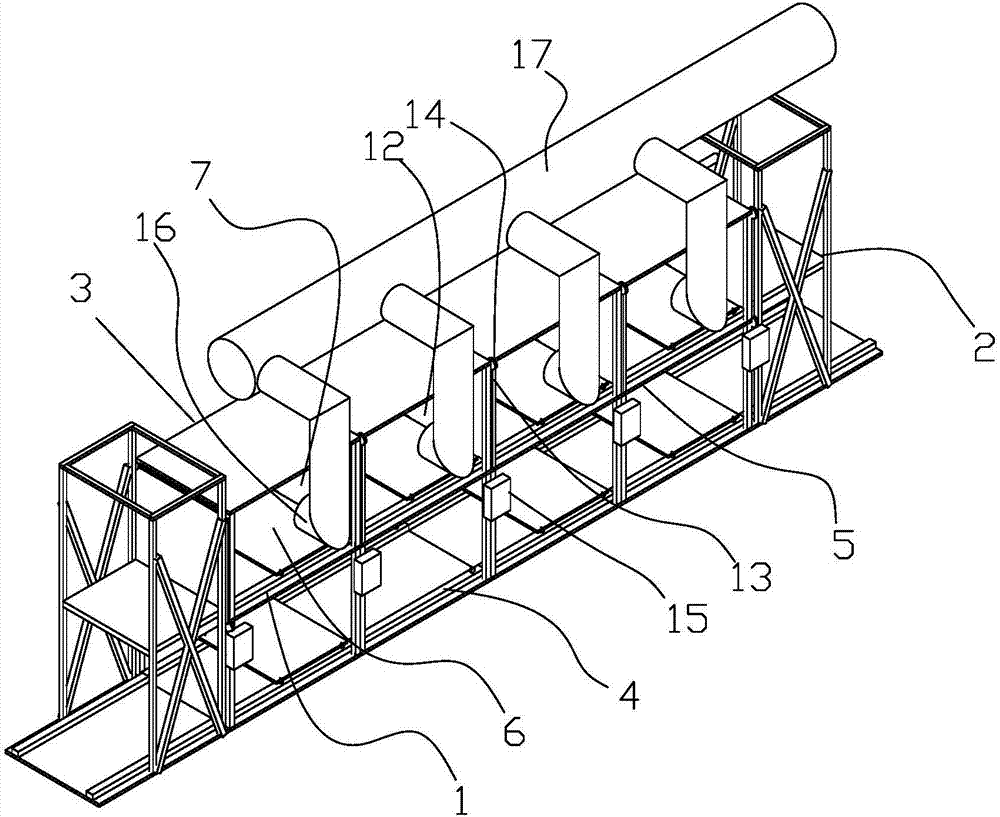

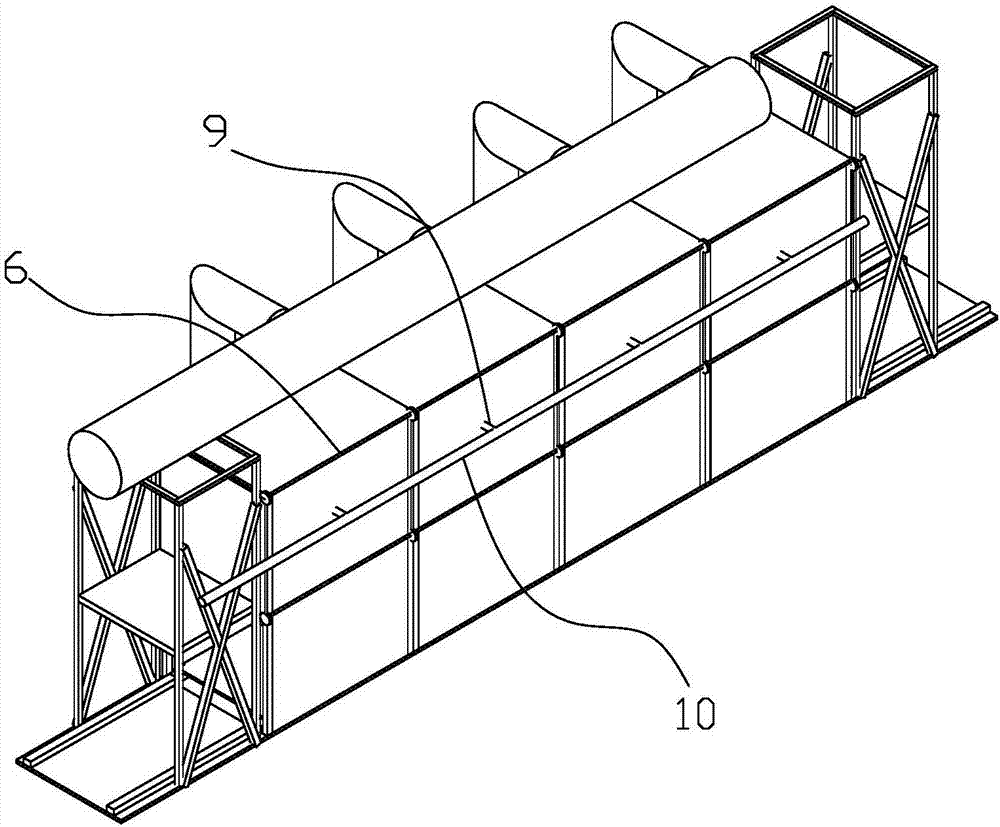

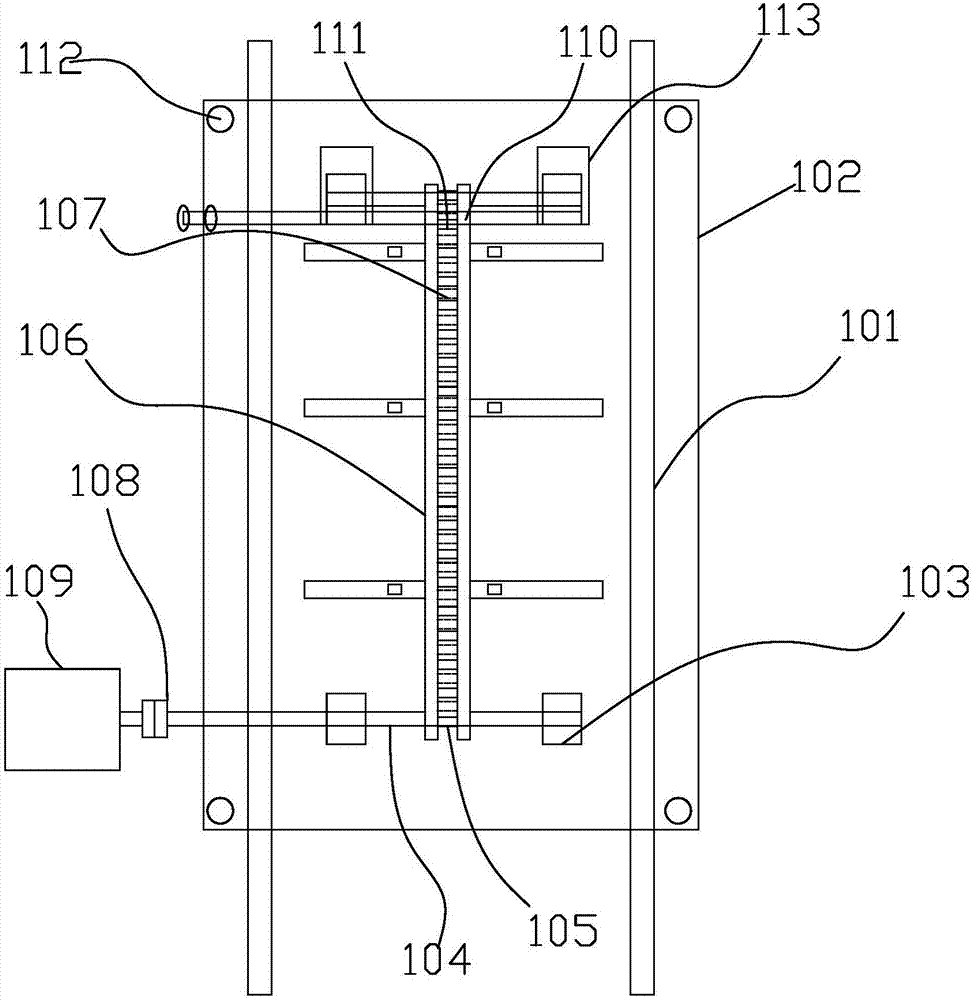

[0021] Examples. A double-layer type garbage pyrolysis tunnel kiln, composed as Figure 1-2 As shown, it includes a double-layer garbage pyrolysis tunnel kiln body 5, the two ends of the double-layer garbage pyrolysis tunnel kiln body 5 are respectively provided with lifting mechanisms 2 (conventional can be used); the double-layer garbage pyrolysis tunnel kiln The body 5 includes an upper combustion kiln body 3 and a lower cooling carriage kiln body 4, the upper combustion kiln body 3 includes a plurality of successively connected and connected combustion kiln units 6, a gate 7 is provided between the combustion kiln units 6, and the lower level The cooling carriage kiln body 4 includes a plurality of successively connected and connected cooling kiln units 8; each of the combustion kiln unit 6 and the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com