Crop harvester

A technology for harvesting machines and crops, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc. It can solve the problems of poor separation between crops and soil, poor soil adaptability, and scattered crops, so as to achieve fast and easy soil leakage. Harvest and damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

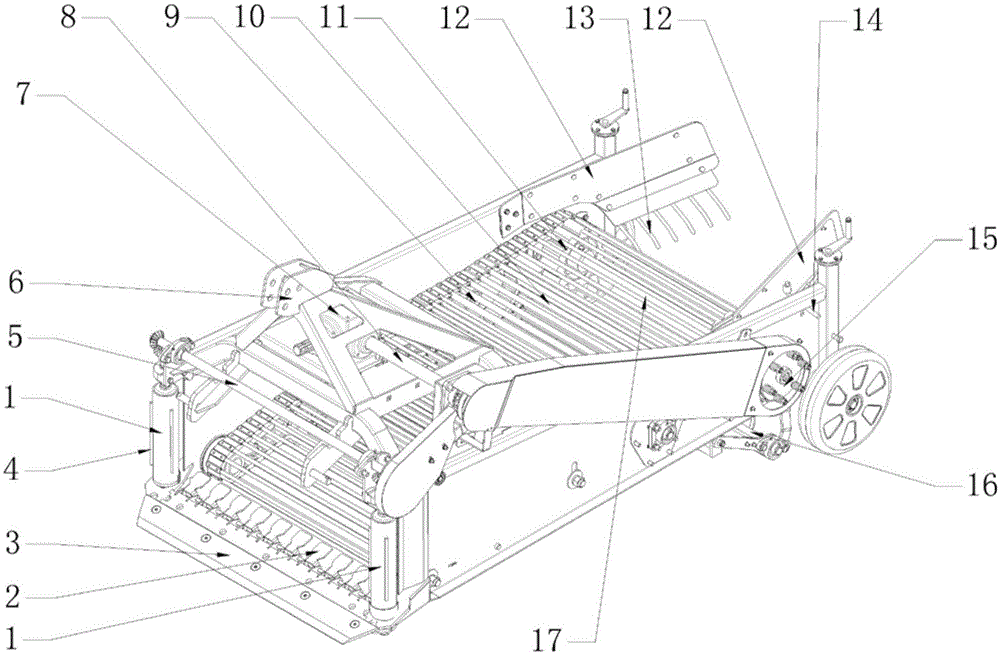

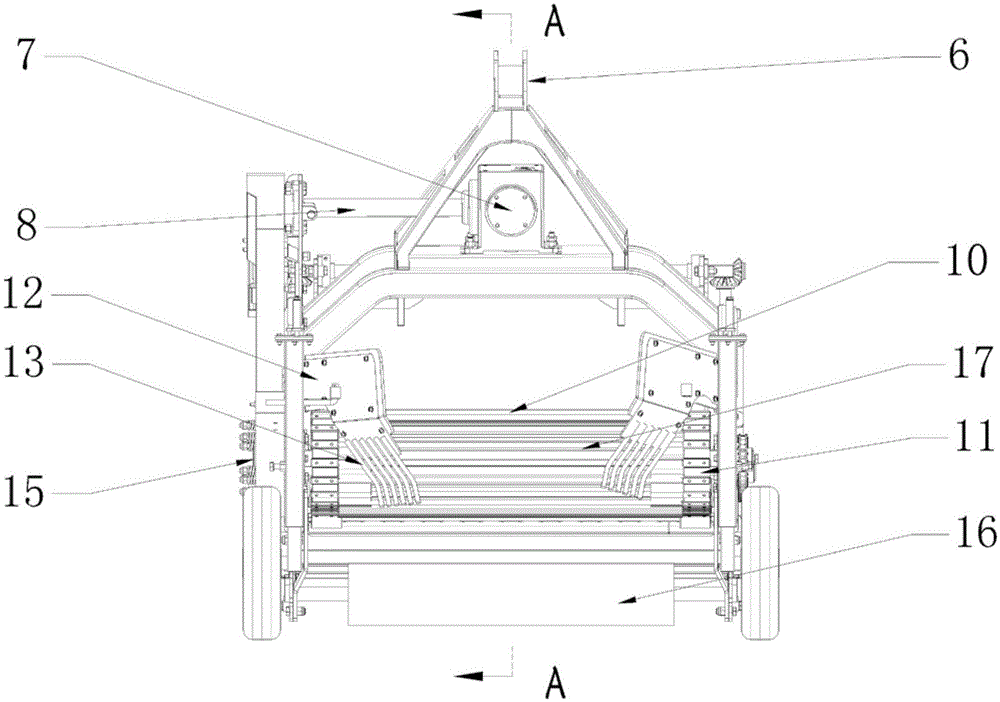

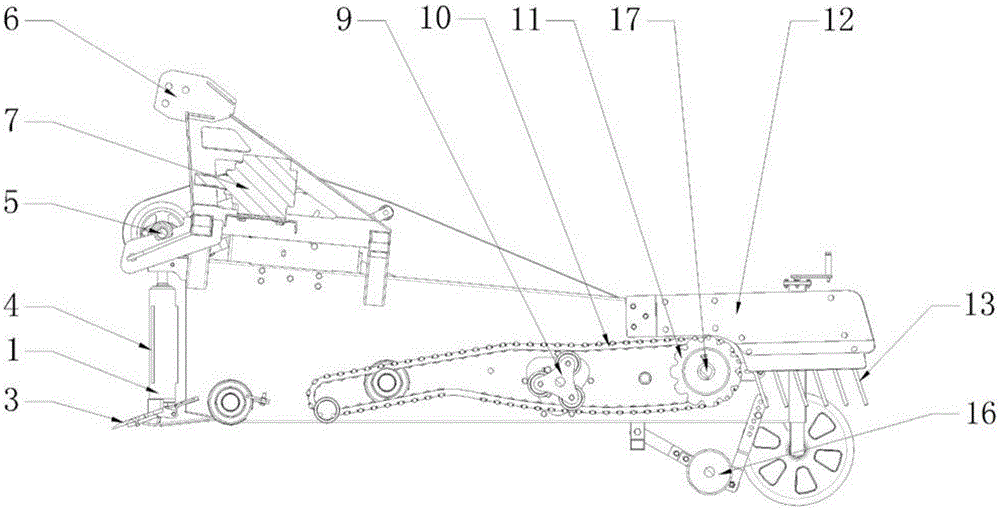

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, the rhizome crop harvester includes a frame, a blade 3 positioned at the front end of the frame, and a vibrating screen 10. At the rear, vertical rotating rollers 1 are respectively arranged on both sides of the rear portion of the blade 3. There is a gap between the rotating roller 1 and the frame. The gap can allow crop seedlings and weeds to pass through. The two rotating rollers 1 and the power shaft 5 is connected, and the power shaft 5 is connected with the motor 7. The bottom of the rotating roller 1 is provided with a bearing seat 21, and the middle part of the bearing seat 21 is provided with a bearing seat shaft 22. There are three pairs of annular seals 23 between the bearing seat 21 and the bearing seat shaft 22, which are located between the bearing seat 21 and the bearing seat. In the gap between the shafts 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com