Preparation technology of hydrophilic stain-resisting textile fabric

A technology of textile fabrics and preparation process, applied in the field of textile fabrics, can solve the problems of poor durability, weakened hydrophilic and anti-fouling ability, poor hydrophilic and anti-fouling effect, etc., and achieve the effect of improving the quality of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

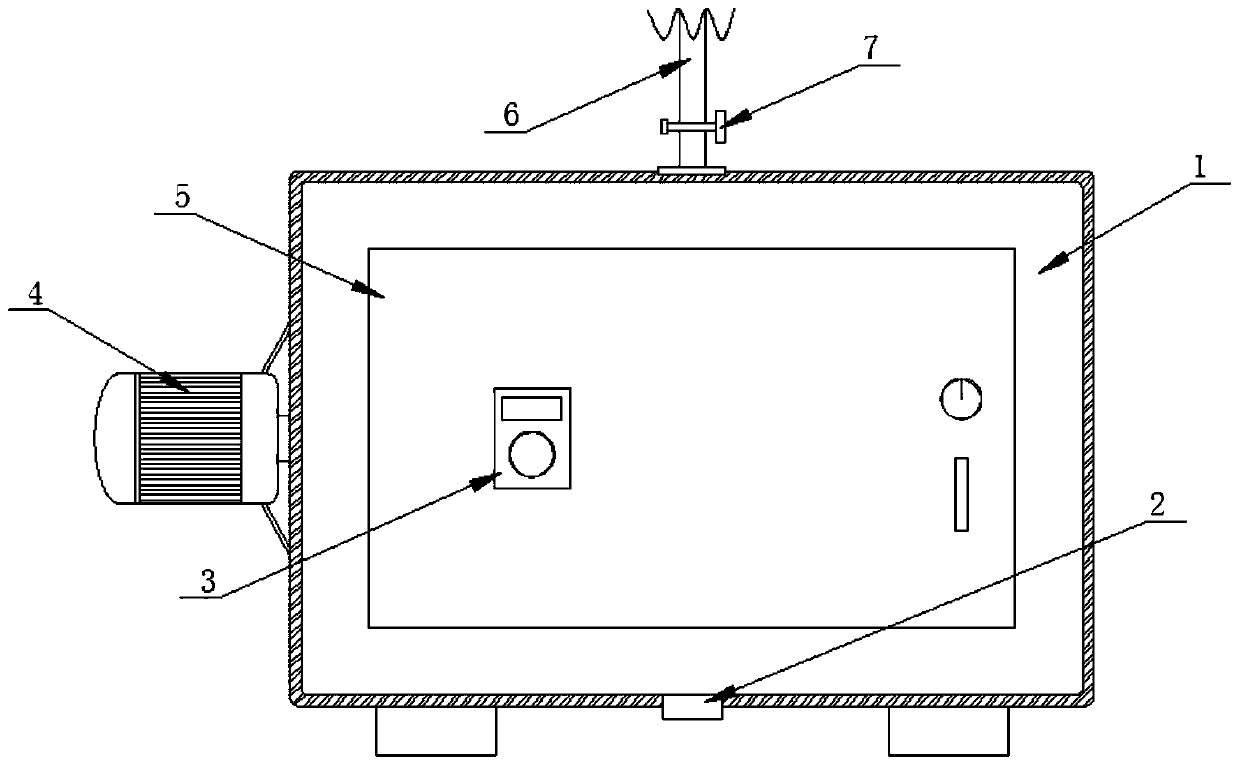

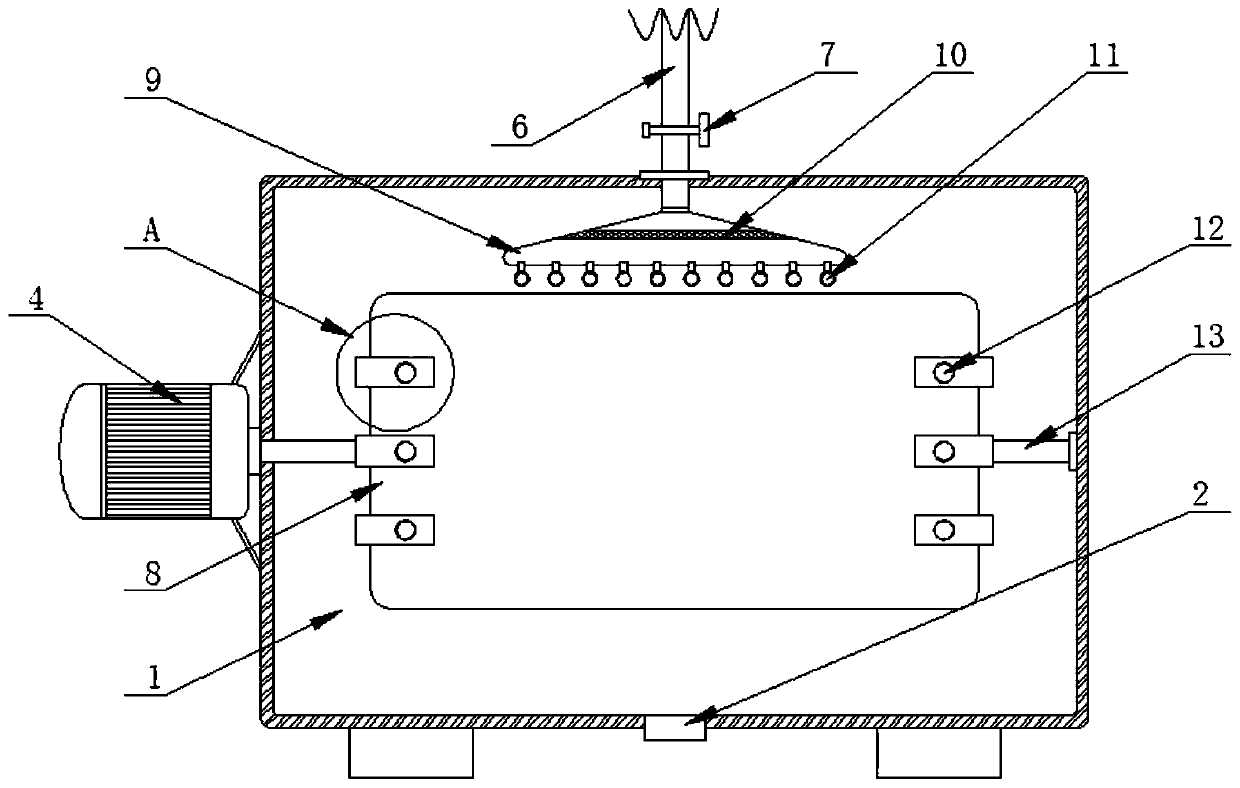

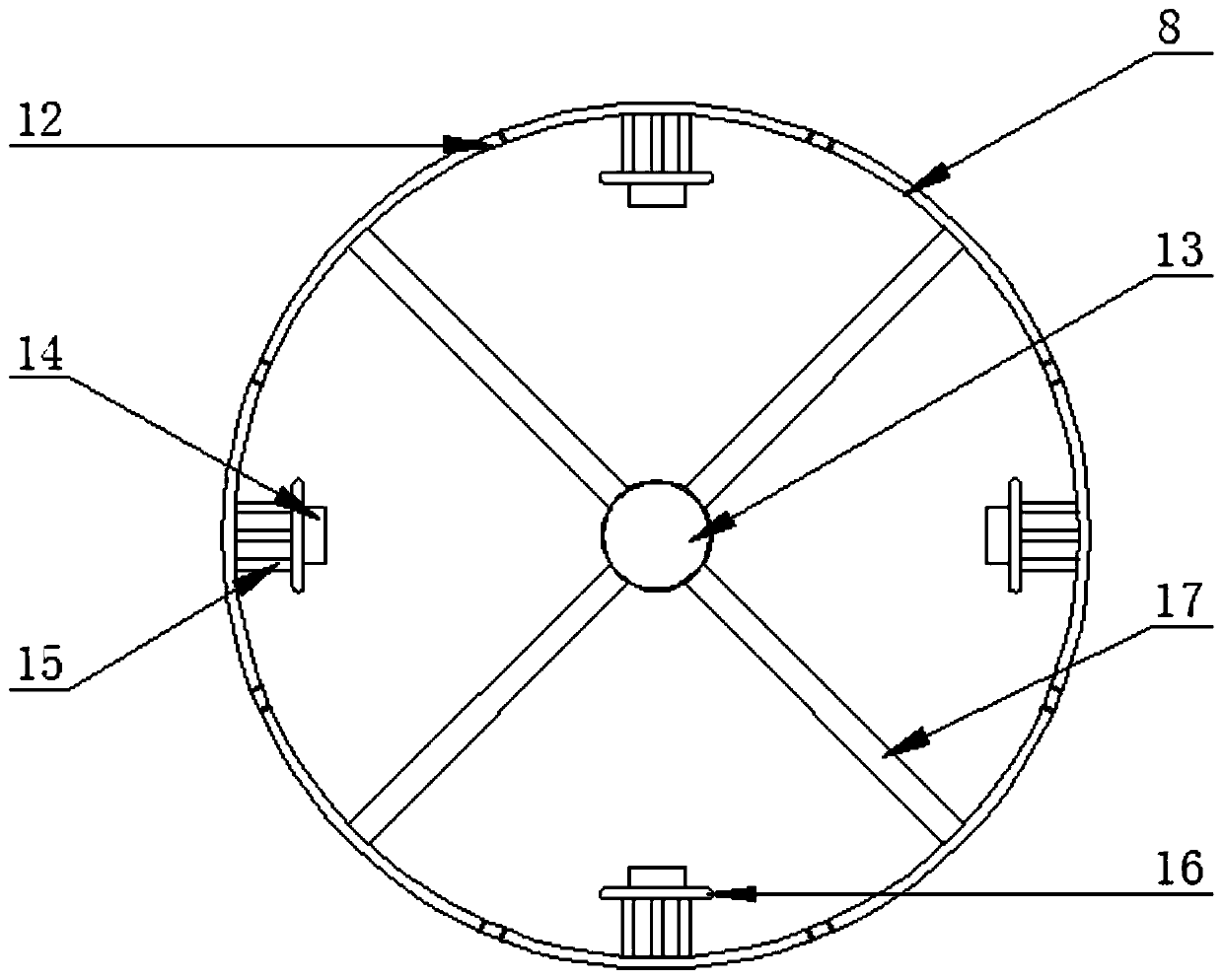

Image

Examples

Embodiment 1

[0032] A preparation process for a hydrophilic and stain-resistant textile fabric. The hydrophilic and stain-resistant textile fabric is composed of two polyester fiber textile fabrics, and the two sides of the polyester fiber textile fabric are respectively marked as side A With side B, the thickness of each piece of textile fabric made of polyester fiber is 1.0mm;

[0033] And the preparation process of the hydrophilic stain-resistant textile fabric comprises the following steps:

[0034] 1) After kneading and steaming the polyester fiber textile fabric first, then grind the A side until fluffing, so as to obtain the primary fabric;

[0035] 2) First soak the primary fabric in acetone solution at 30 degrees, then add a blend of tert-butyl peroxybenzoate and polyacrylate, and raise the temperature to 90 degrees for 60 minutes, after cooling and drying , to get the secondary fabric;

[0036] 3) Mix pure water and sodium dodecylsulfonate at 60 degrees, put the secondary fabri...

Embodiment 2

[0041] A preparation process for hydrophilic and stain-resistant textile fabrics, the difference from Example 1 is that there is no step 1).

Embodiment 3

[0043] A kind of preparation technology of hydrophilic stain-resistant textile fabric, and the difference in embodiment 1 is, 2) earlier primary fabric is soaked in the acetone solution of 30 degrees, then adds tert-butyl peroxybenzoate and The blend solution of polyacrylate, and warming up to 90 degrees and soaking for 60 minutes, after cooling and drying, to obtain the secondary fabric; and the weight percentages of acetone solution, tert-butyl peroxybenzoate and polyacrylate are respectively 9:0.5:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com