High-filtration-loss plugging agent specially used for oil-based drilling fluid

An oil-based drilling fluid and plugging agent technology, which is applied in the field of petroleum drilling engineering, can solve the problems of lack of suitable high fluid loss plugging agents, etc., and achieve the effects of wide application range, quick effect, and simple plugging construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

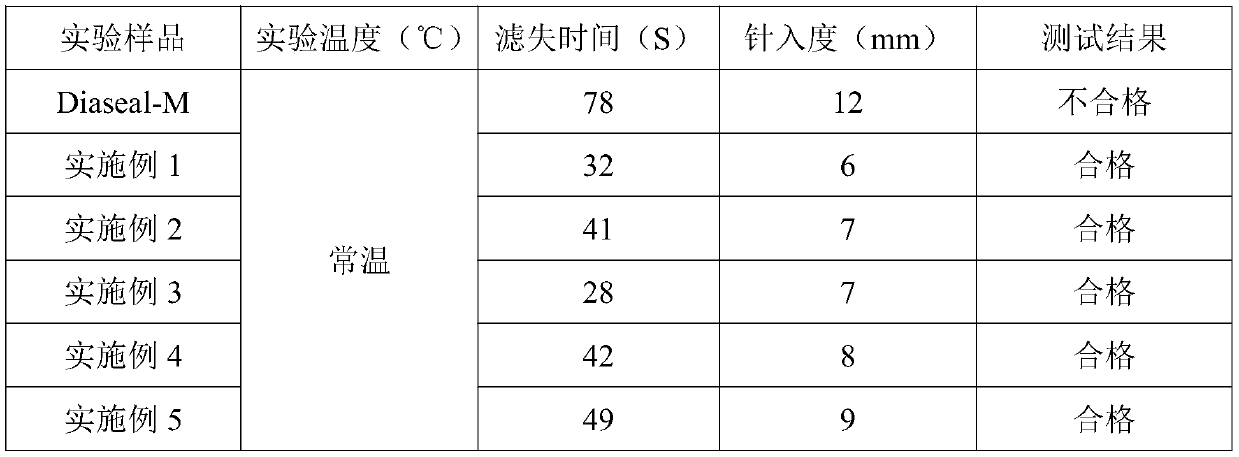

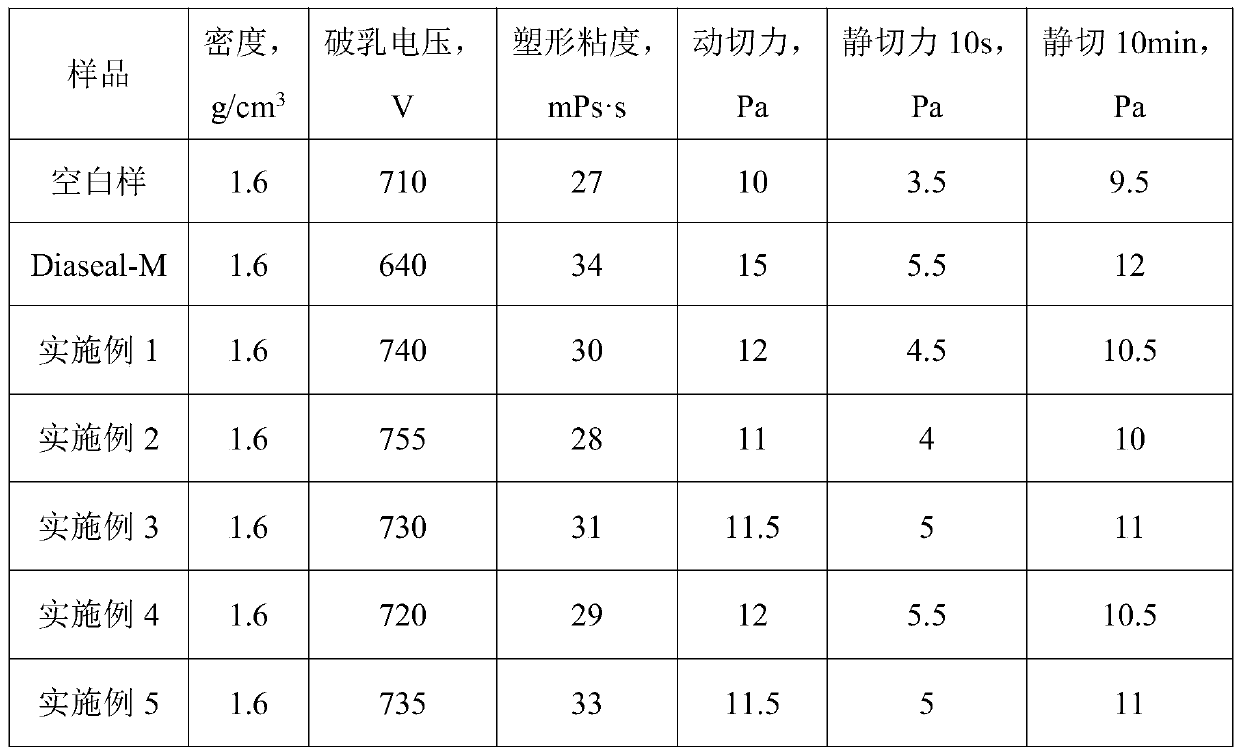

Examples

Embodiment 1

[0020] A special high fluid loss plugging agent for oil-based drilling fluid, the component content of which is: 10g of polyamide fiber, 60g of porous inert ceramic powder, 20g of zeolite powder, and 10g of lime powder. Among them, in the ceramic powder, the weight ratio of the 180-mesh ceramic powder to the 250-mesh ceramic powder is =6:4; in the zeolite powder, the weight ratio of the 100-mesh zeolite powder to the 150-mesh zeolite powder is 4:6. All the components are mixed evenly to obtain the plugging agent.

Embodiment 2

[0022] A special high fluid loss plugging agent for oil-based drilling fluid, the component content of which is: 5g of polyamide fiber, 65g of porous inert ceramic powder, 20g of zeolite powder, and 10g of lime powder. Among them, in ceramic powder, the weight ratio of 180-mesh ceramic powder to 250-mesh ceramic powder is =6:5; in zeolite powder, the weight ratio of 100-mesh zeolite powder to 150-mesh zeolite powder is 4:7. All the components are mixed evenly to obtain the plugging agent.

Embodiment 3

[0024] A special high fluid loss plugging agent for oil-based drilling fluid, its component content is: 10g polyamide fiber, 55g porous inert ceramic powder, 25g zeolite powder, 10g lime powder; among them, in the ceramic powder, 180 mesh ceramic The weight ratio of the powder to the 250-mesh ceramic powder is =2:1; in the zeolite powder, the weight ratio of the 100-mesh zeolite powder to the 150-mesh zeolite powder is 1:1. All the components are mixed evenly to obtain the plugging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com