Sand-barrier manufactured by biodegradable material

A biodegradable material and sand barrier technology, applied in the field of sand barriers, can solve the problems of degradation of sand barriers, decreased sand moving performance, poor aging resistance of natural fibers, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

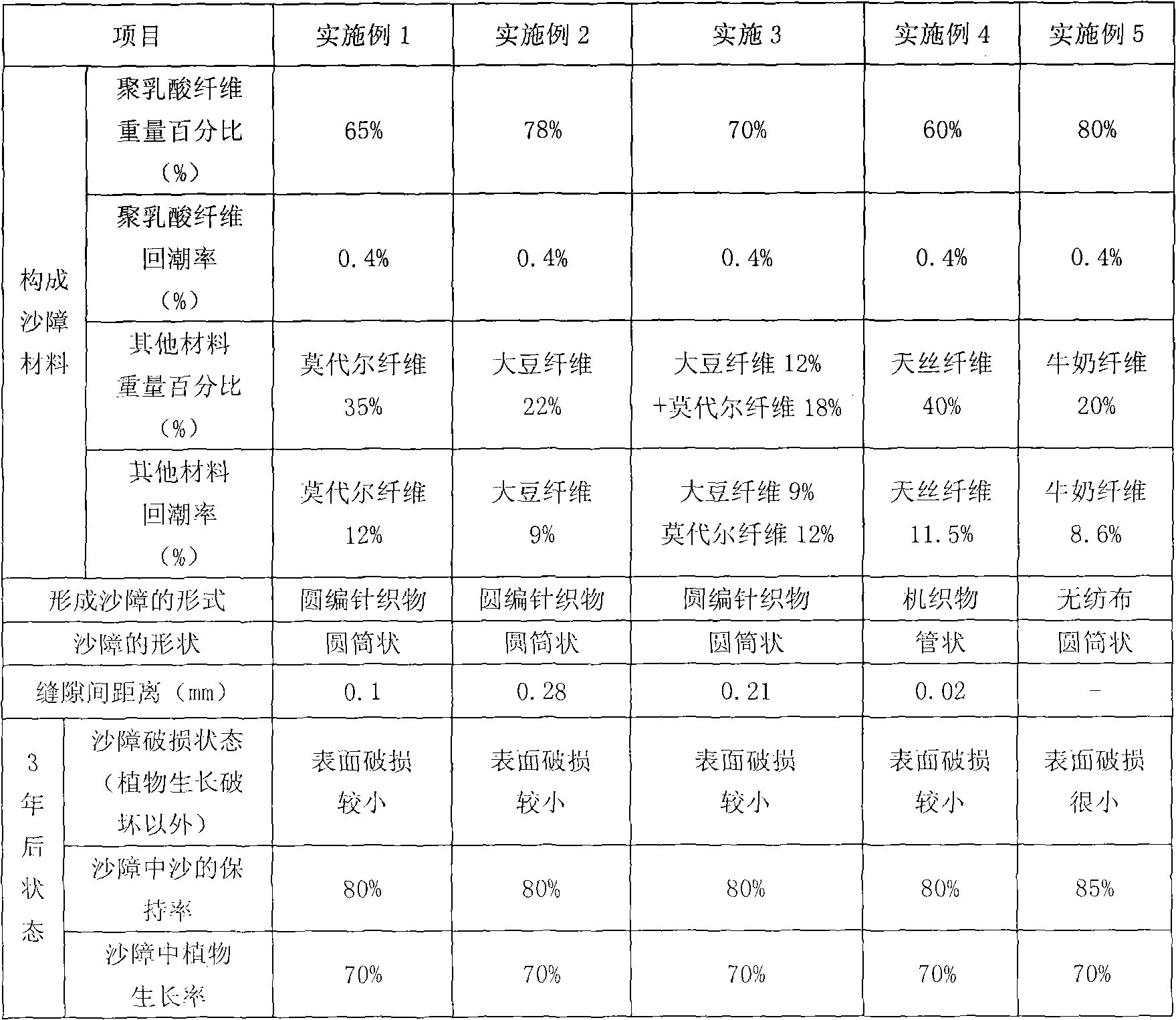

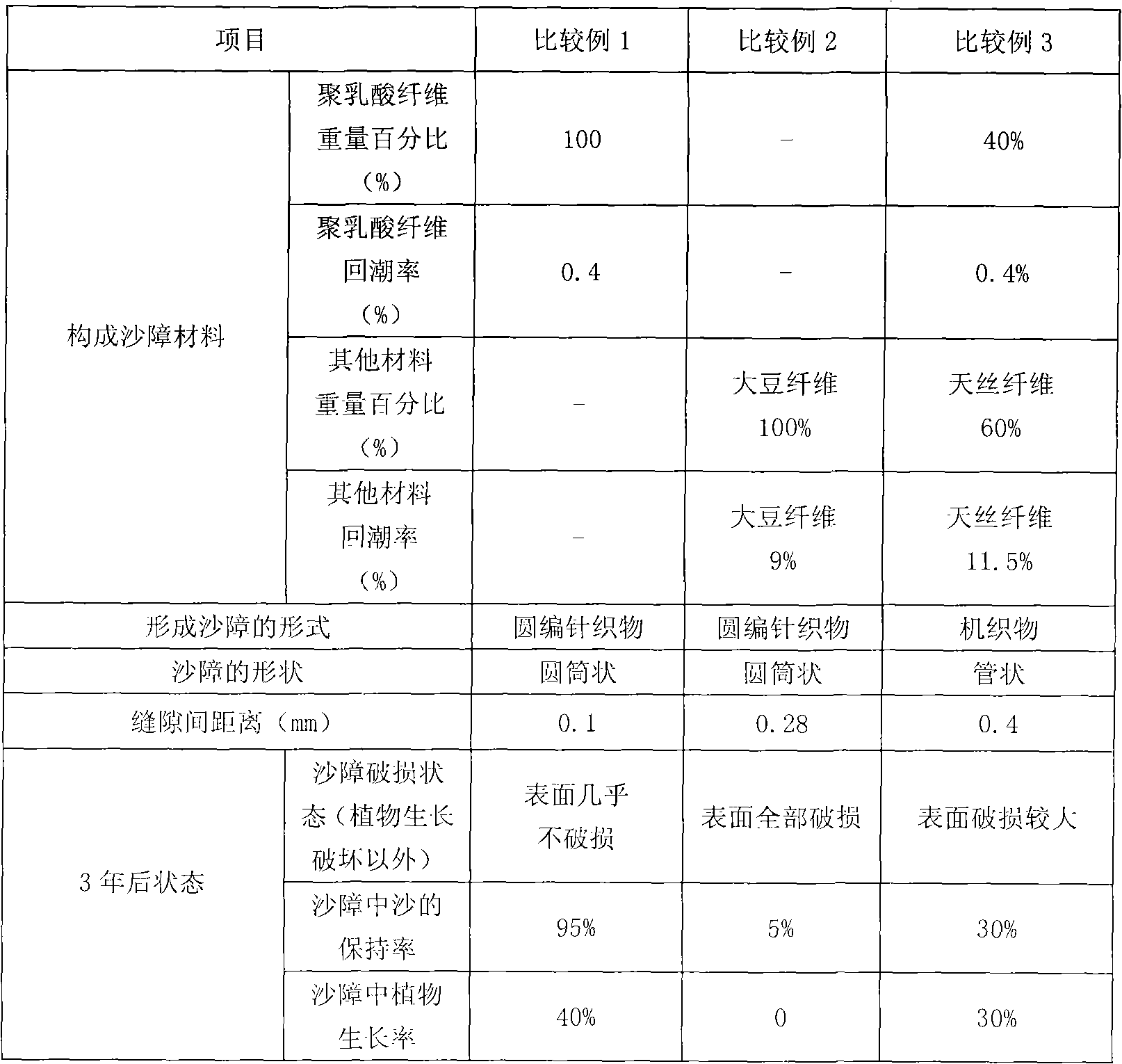

Embodiment 1

[0022] The polylactic acid fiber with a moisture regain of 0.4% and the modal fiber with a moisture regain of 12% are woven into a knitted fabric by a circular knitting machine, and a cylindrical sand barrier is made with the above knitted fabric, and the polylactic acid fiber in the sand barrier is The weight percentage is 65%, and the weight percentage of the modal fiber is 35%. The distance between the gaps of the above-mentioned knitted fabrics is 0.1mm, and they are placed in the Jilantai Desert in Inner Mongolia, and the damage state of the sand barrier and the growth state of the plants in the sand barrier are observed after 3 years, see Table 1.

Embodiment 2

[0024] The polylactic acid fiber with a moisture regain of 0.4% and the soybean fiber with a moisture regain of 9% are woven into a knitted fabric by a circular knitting machine, and a cylindrical sand barrier is made with the above knitted fabric. The weight of the polylactic acid fiber in this sand barrier is The percentage is 78%, and the weight percentage of soybean fiber is 22%. The distance between the gaps of the above knitted fabrics is 0.28 mm, placed in the Jilantai Desert in Inner Mongolia, and the damage state of the sand barrier and the growth state of the plants in the sand barrier were observed after 3 years, see Table 1.

Embodiment 3

[0026] Polylactic acid fiber with a moisture regain of 0.4%, soybean fiber with a moisture regain of 9% and modal fiber with a moisture regain of 12% are woven into knitted fabrics with a circular knitting machine, and a cylindrical sand barrier is made with the above knitted fabrics. The weight percentage of polylactic acid fiber in the sand barrier is 70%, the weight percentage of soybean fiber is 12%, and the weight percentage of modal fiber is 18%. The distance between the gaps of the above knitted fabrics is 0.21 mm, placed in the Jilantai Desert in Inner Mongolia, and the damage state of the sand barrier and the growth state of the plants in the sand barrier were observed after 3 years, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com