Blended yarn of polyamide fiber and cotton as well as preparation method and application of blended yarn

A blended yarn and polyamide technology, applied in textiles and papermaking, yarn, textile, etc., can solve the problems of poor spinnability and yarn quality, and achieve the effects of good resilience, excellent wear resistance and high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

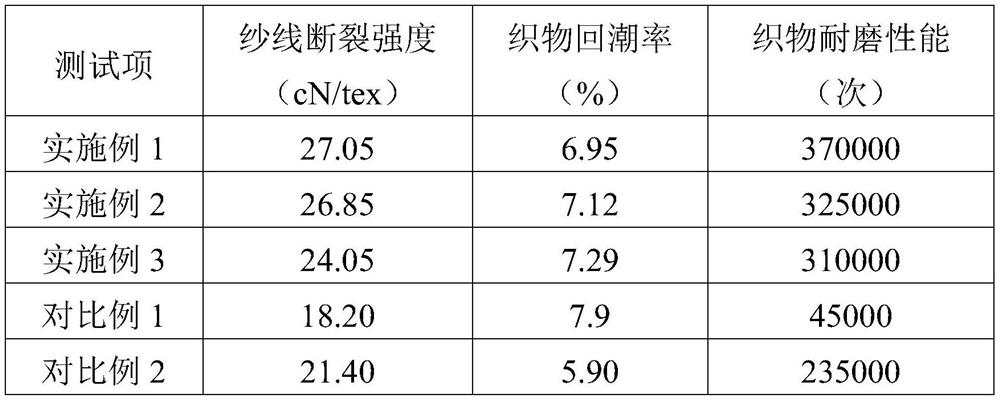

Examples

Embodiment 1

[0071] The preparation method of the blended yarn of the polyamide 56 fiber of the present embodiment and cotton is as follows:

[0072] Take 30kg of polyamide 56 fiber, use 180g Yuanchuang Oil Agent J5326-H Nylon Staple Fine Denier Finishing Spinning Oil Agent (antistatic agent) and 1.8kg of soft water above 90°C to mix evenly, and then spray the solution evenly through a watering can Place it on the polyamide 56 fiber at 28°C, 65% R.H. for 2 hours.

[0073] The specification of the polyamide 56 fiber used is: the linear density is 1.67dtex, the length is 38mm; the breaking strength of the polyamide 56 fiber is 6.5cN / dtex.

[0074] After 24 hours of treatment, the moisture regain of polyamide 56 fiber reaches 6.14%, and the mass specific resistance reaches 1×10 6 (Ω·g·cm -3 ), has good spinnability, and then the polyamide 56 fiber is subjected to opening and cleaning, carding and a pre-combination process, and finally the fixed weight of the pre-combined fiber strip is 18.7...

Embodiment 2

[0079] The preparation method of the blended yarn of the polyamide 56 fiber of the present embodiment and cotton is as follows:

[0080] Take 25kg of polyamide 56 fiber, mix it with 1.8kg of soft water above 90℃ with 180g of Yuanchuang Oil Agent J5326-H Nylon Staple Fine Denier Yarn Spinning Oil Agent (antistatic agent) and mix evenly, then spray the solution evenly through the nozzle Place it on polyamide 56 fiber for 24 hours at 26°C and 67% R.H.

[0081] The specification of the polyamide 56 fiber used is: the linear density is 1.67dtex, the length is 38mm; the breaking strength of the polyamide 56 fiber is 6.0cN / dtex.

[0082] After 24h treatment, the moisture regain of polyamide 56 fiber reaches 6.10%, and the mass specific resistance reaches 1.2×10 6 (Ω·g·cm -3 ), has good spinnability, and then the polyamide 56 fiber is subjected to opening and cleaning, carding and a pre-combination process, and finally the pre-combined fiber strip has a fixed weight of 21.2g / 5m, and...

Embodiment 3

[0087]The preparation method of the blended yarn of the polyamide 56 fiber of the present embodiment and cotton is as follows:

[0088] Take 25kg of polyamide 56 fiber, use 180g of Yuanchuang oil agent J5326-H nylon short filament fine denier post-spinning oil agent (antistatic agent) and 1.8kg of soft water above 90°C to mix evenly, and then pass the watering can head to evenly mix the solution Spray on the polyamide 56 fiber and place it at 29°C, 68% R.H. for 24h.

[0089] The specification of the polyamide 56 fiber used is: the linear density is 1.67dtex, the length is 38mm; the breaking strength of the polyamide 56 fiber is 5.8cN / dtex.

[0090] After 24 hours of treatment, the moisture regain of polyamide 56 fiber reaches 5.80%, and the mass specific resistance reaches 1.3×10 6 (Ω·g·cm -3 ), has good spinnability, and then the polyamide 56 fiber is subjected to opening and cleaning, carding and a pre-combination process, and finally the weight of the pre-combination fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com