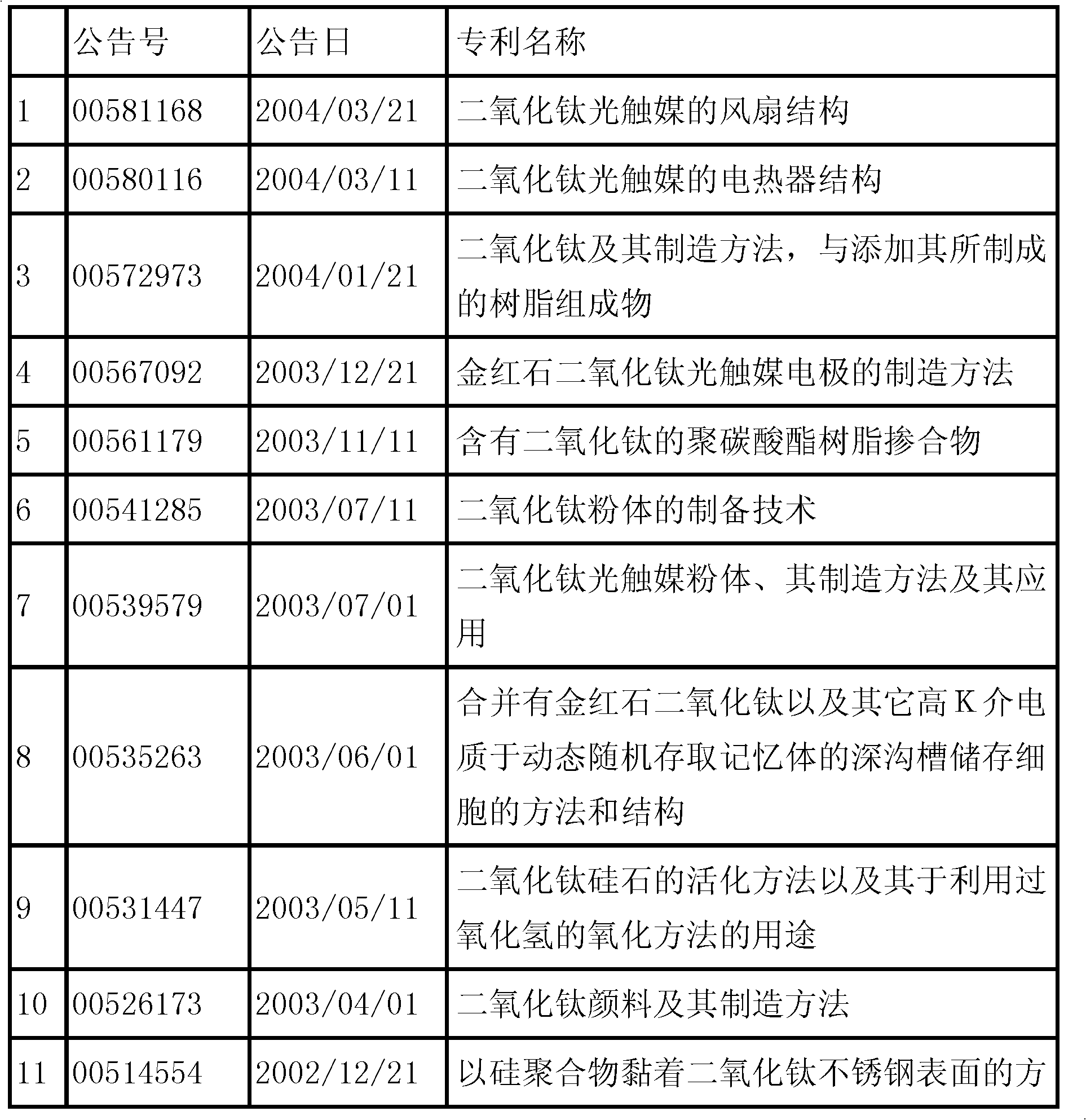

Patents

Literature

69results about How to "Improve hydrophilic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

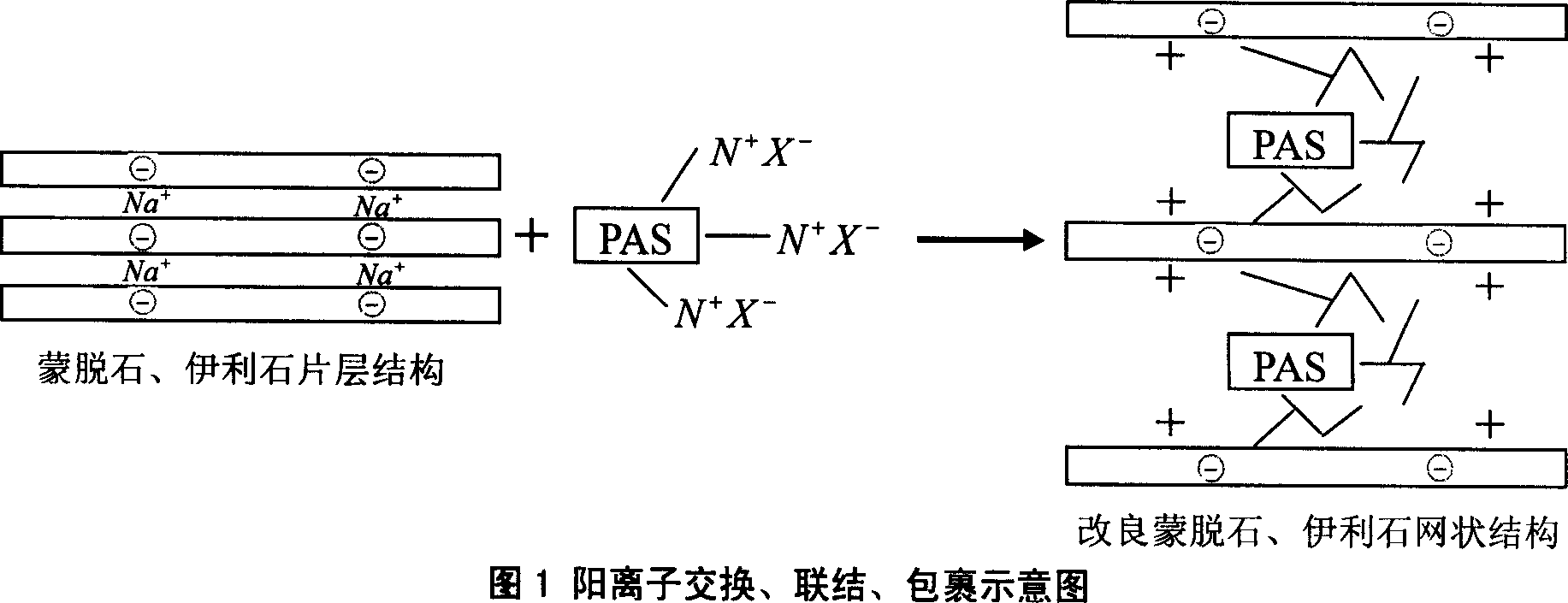

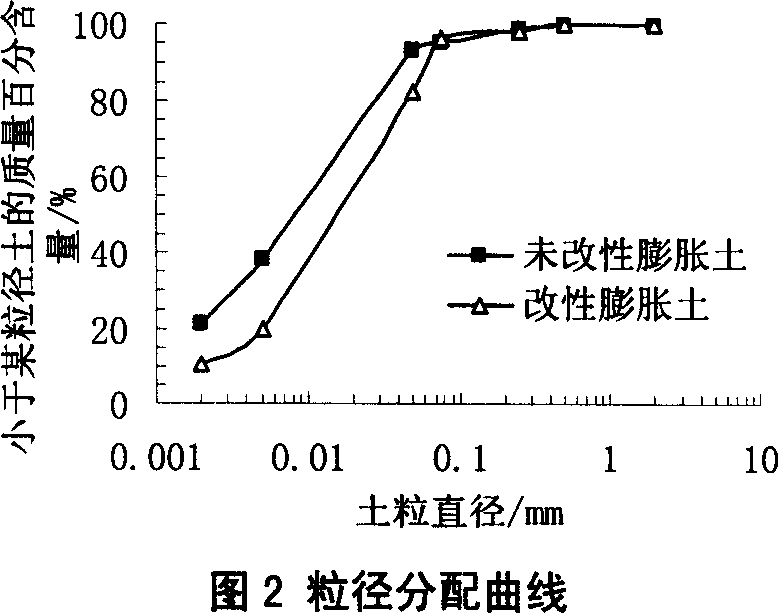

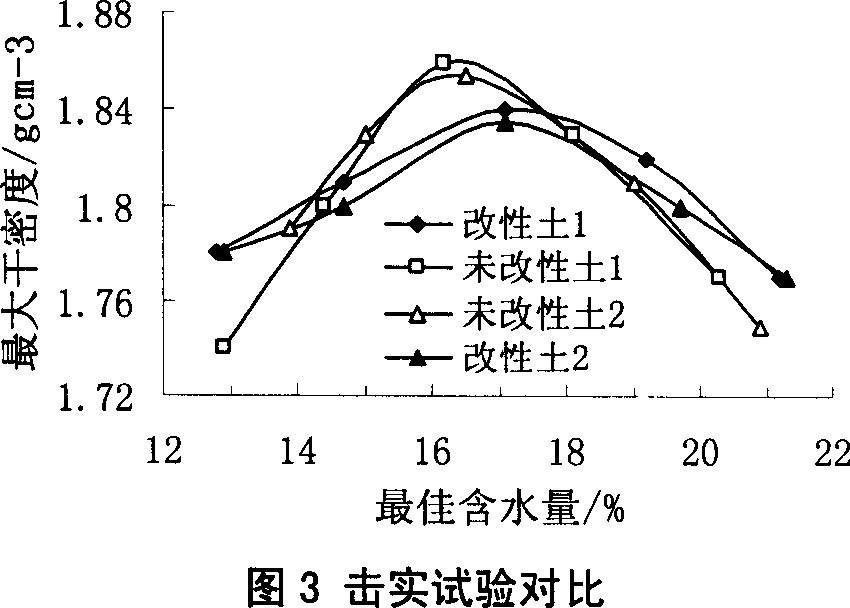

Chemical modifying method for swelled ground treatment

InactiveCN101063036AReduce expansionImprove hydrophilic propertiesBuilding constructionsOrganic fertilisersChemical reactionWater soluble

The invention discloses a chemical improved method to harness swelled ground, which comprises the following steps: allocating swelled ground PAS chemical modifying agent with silicate of soda + basic ion polyacrylamide + water; spraying modifying agent on swelled ground body; changing, linking, bundling, birdnesting, and jelling with ground body particle ion; forming space network structure; increasing physical mechanics property and engineering feature of swelled ground; meeting engineering construction demand of swelled ground. This invention possesses good water stable effect and even modification, which is fit for construction foundation treatment, highway engineering earth bank, slope harness and so on swelled ground project.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

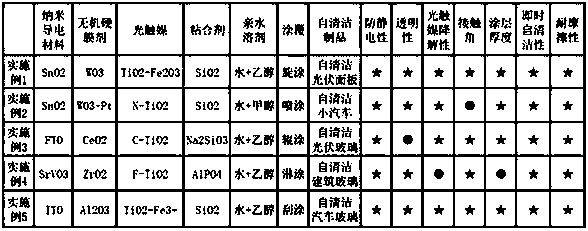

Composite self-cleaning nanometer coating, inorganic transparent coating layer and self-cleaning product

InactiveCN107892826AImprove hydrophilic propertiesImprove anti-staticAntifouling/underwater paintsPaints with biocidesSpecific functionBird droppings

The invention reveals a composite self-cleaning nanometer coating, an inorganic transparent coating layer and a self-cleaning product. The coating, the coating layer and the product have anti-static,super-hydrophilic and photocatalytic functions at a same time. The composite self-cleaning nanometer coating containing 0.01-20 parts of conductive particles, 0.01-20 parts of a photocatalyst, 0.01-20parts of a hard film agent, 0.01-20 parts of an inorganic binder and 20-99.96 parts of a hydrophilic solvent is prepared. The surface of an object is coated with the composite self-cleaning nanometercoating, and the composite self-cleaning nanometer coating is solidified for forming a hydrophilic inorganic transparent coating layer. Because of specific functions of static electricity conductionand static electricity dissipation of the coating layer, static electricity generated when the surface of the object rubs flowing air can be instantly eliminated, and the surface of the object loses the attraction to particles in the surrounding environment in microstructure, so that sand, dust, pollen, haze and the like are difficult to attach to the surface of the object, and thus an instant self-cleaning effect of keeping the surface of the object clean at any time is achieved. The coating layer also has a photocatalyst degradation function and can be used for remarkably solving the problemof high-adhesive-force dirt caused by non-electrostatic adsorption of bird droppings, ink, artificial scrawling and the like.

Owner:ZHANGJIAGANG ALIEN NEW MATERIAL TECH CO LTD

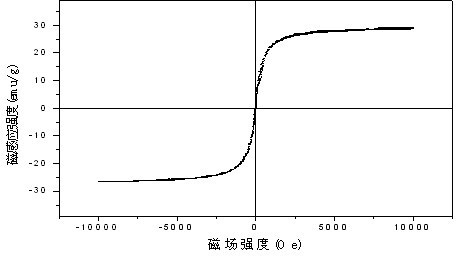

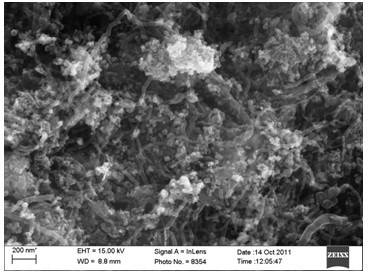

Method for removing mercury ions in water and regeneration method of adsorbent used in same

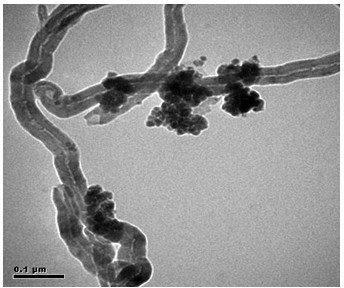

InactiveCN102432085ANanostructure, large specific surface areaLarge specific surface areaOther chemical processesCombustible gas purificationSorbentModified carbon

The invention relates to a method for removing mercury ions in water and a regeneration method of an adsorbent used in the same. An adsorbent is put in water to be treated to adsorb mercury ions in the water. The adsorbent is a palladium nanoparticle supported / iron oxide magnetic modified carbon nanotube composite material. The carbon nanotube composite material provided by the invention has nanostructure and large specific area; and after the carbon nanotube composite material is oxidized and activated, carboxyl group, hydroxyl group and other active functional groups are formed on the surface of the carbon nanotube composite material, thereby enhancing the hydrophilic property and the adsorptive capacity for positively charged metallic ions. The iron oxide is coated on the surface of the activated carbon nanotube composite material, and therefore, the activated carbon nanotube composite material has strong soft magnet property, and can easily implement solid-liquid separation of the adsorbent and the polluted water body under the action of an external magnetic field. The palladium modification strengthens the affinity of the composite material with mercury ions, and greatly enhances the adsorption capacity and selectivity of the original carbon nanotube composite material for mercury ions (the maximum adsorption capacity is 55.3mg / g).

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

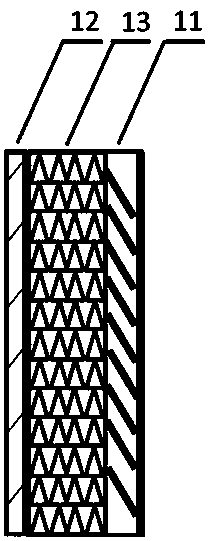

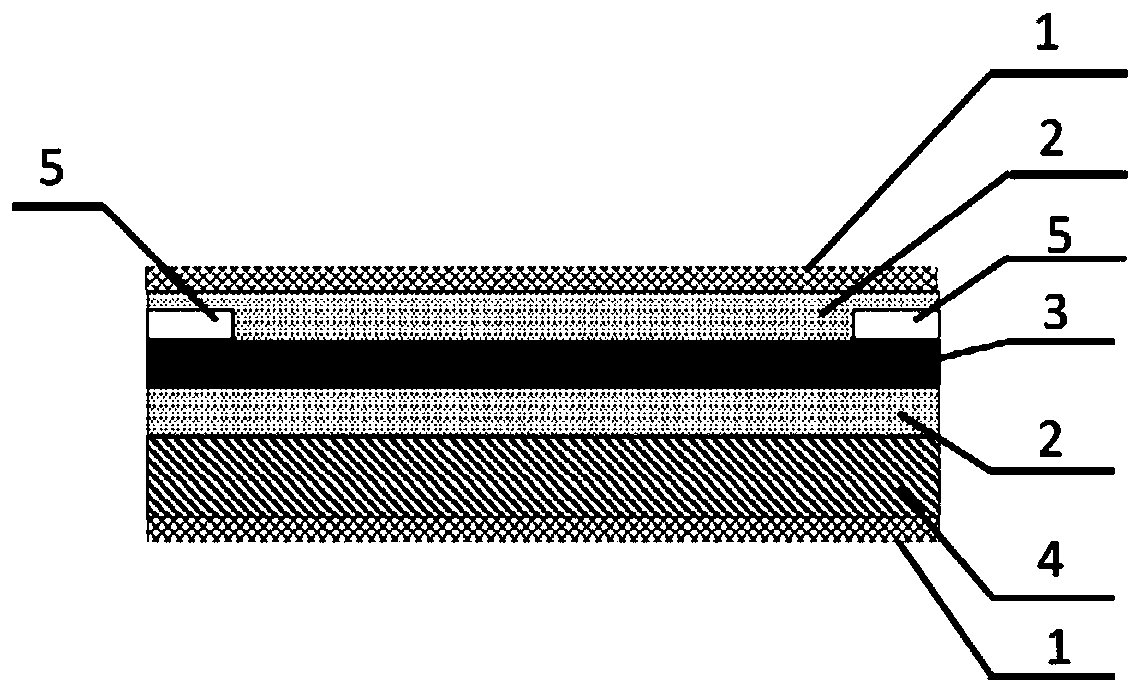

Electric heating film and preparation method and application thereof

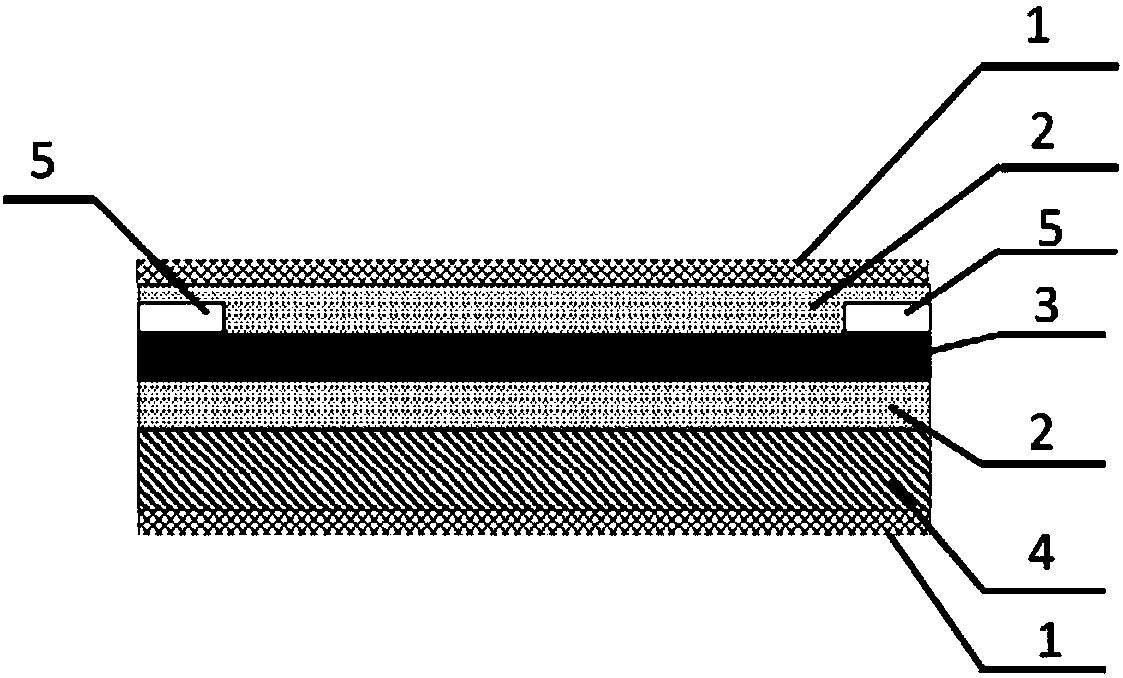

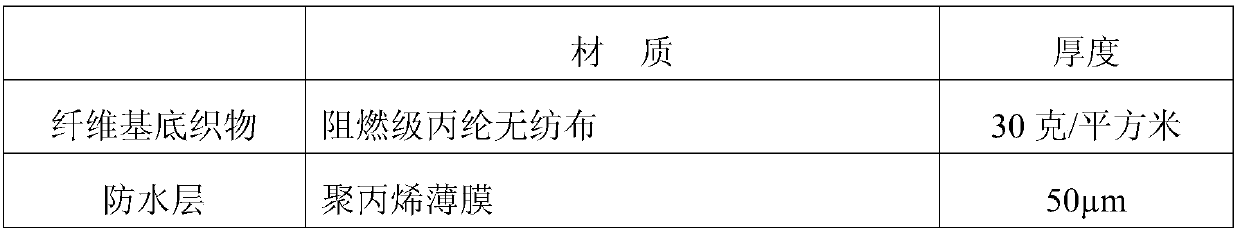

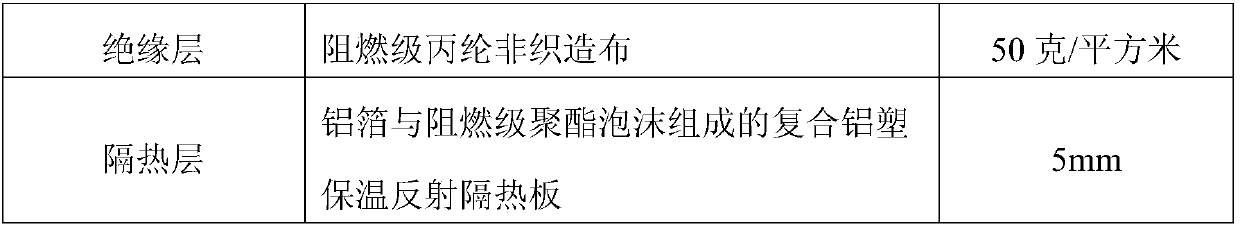

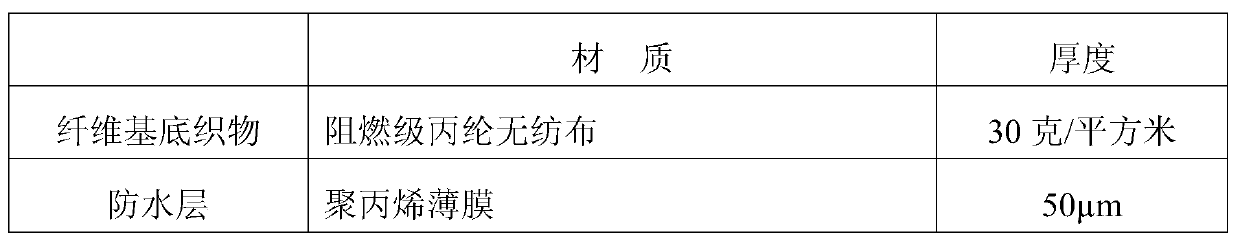

ActiveCN107592688AAvoid electrothermal performance degradationExtended service lifeOhmic-resistance heating detailsHeating element materialsHeating filmThermal insulation

The invention discloses an electric heating film and a preparation method and an application thereof. The electric heating film comprises a waterproof layer, an insulating layer, an electric heating layer, an electrode, an insulating layer, a thermal insulation layer and a waterproof layer and the like; the electric heating layer comprises fiber base fabric, a high-conductivity nanometer carbon material and a functional auxiliary; and the high-conductivity nanometer carbon material is adsorbed on the surface or in the gap of the fiber base fabric. The preparation method comprises the steps oftaking the fiber base fabric as the bearing substrate of the high-conductivity nanometer carbon material, performing wetting to form a hydrophilic treatment liquid firstly, next, performing baking andcuring, then coating with a wetted nanometer carbon aqueous dispersion liquid, and next, performing baking and curing to obtain the electric heating layer; and next, gluing with the insulating layer,the thermal insulation layer, the waterproof layer and the electrode through hot melt adhesive to form the electric heating film. The electric heating film is free of binder resin, so that the problem of electric heating performance degradation caused by resin aging can be obviously avoided; and the electric heating film has the integrated performance of electric heating, waterproof property, thermal insulation, reflection and the like, and can be widely applied to the industries of home heating, floor heating, thermal insulation, industrial heating and the like.

Owner:江西江铜碳纳米材料有限公司

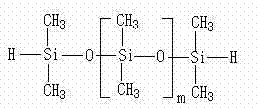

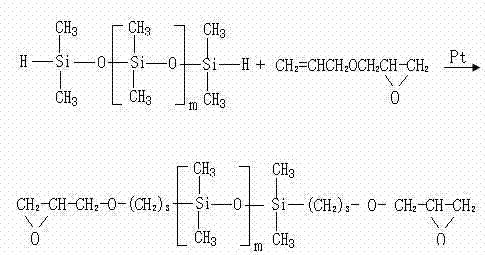

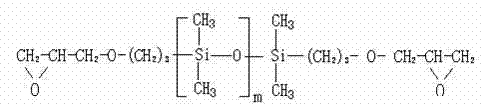

Preparation method of quaternary copolymer block organic silicon oil

The invention relates to a preparation method of quaternary copolymer block organic silicon oil. The preparation method is characterized by comprising the following steps of: A, preparation of a hydrogen-containing silicon oil intermediate I: blocking with a hydrogen-containing sealing agent by taking the polysiloxane as a main raw material to obtain the hydrogen-containing silicon oil intermediate I; B, preparation of an epoxy-terminated block organic silicon oil intermediate II: adding the intermediate I and allyl glycidyl ether to obtain the epoxy-terminated block organic silicon oil intermediate II; and C, preparation of a finished product: grafting anhydrous piperazine and amino-terminated polyether to the main chain of the intermediate II, and finally obtaining the quaternary copolymer block organic silicon oil. Through the invention, the prepared quaternary copolymer block organic silicon oil does not cause the yellowing phenomenon, and has good hydrophily and strong emulsion stability; and good comprehensive handfeel can be obtained by applying a small amount of the quaternary copolymer block organic silicon oil to the textile.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

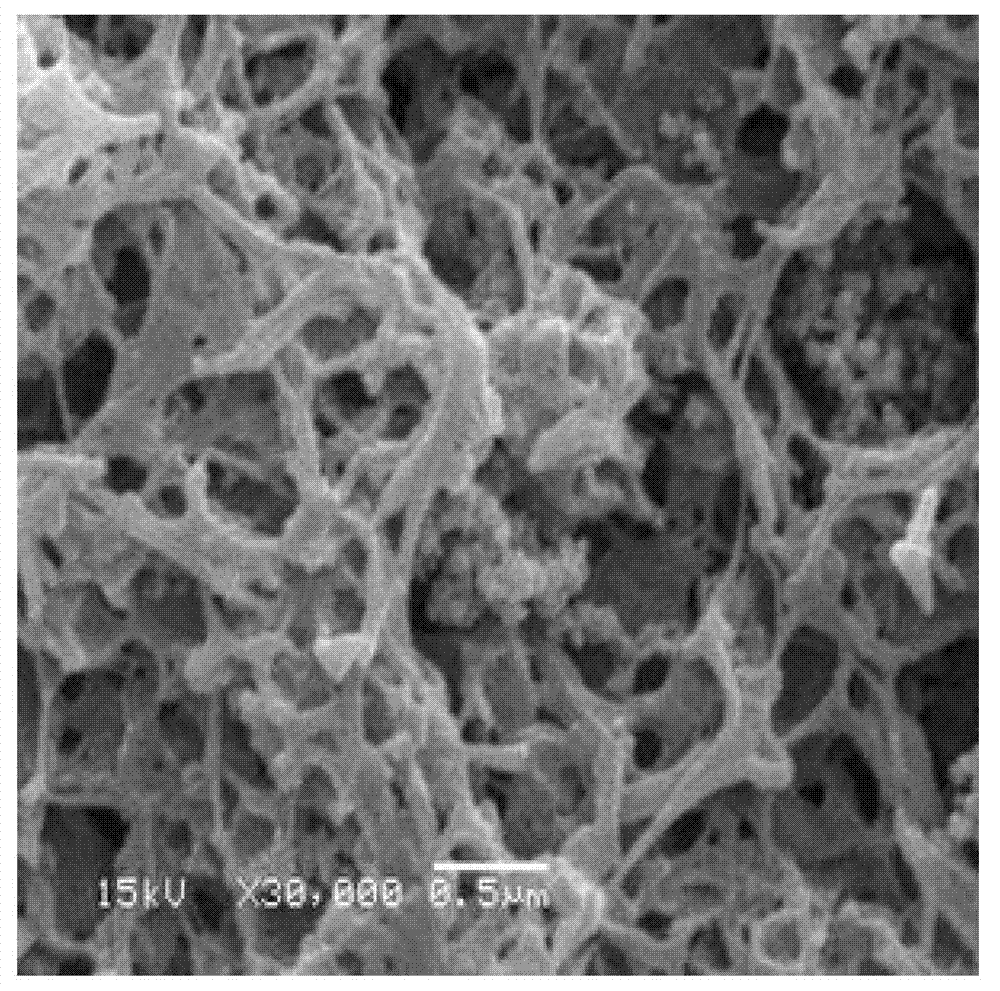

Novel polyvinylidene fluoride film as well as preparation method and application thereof

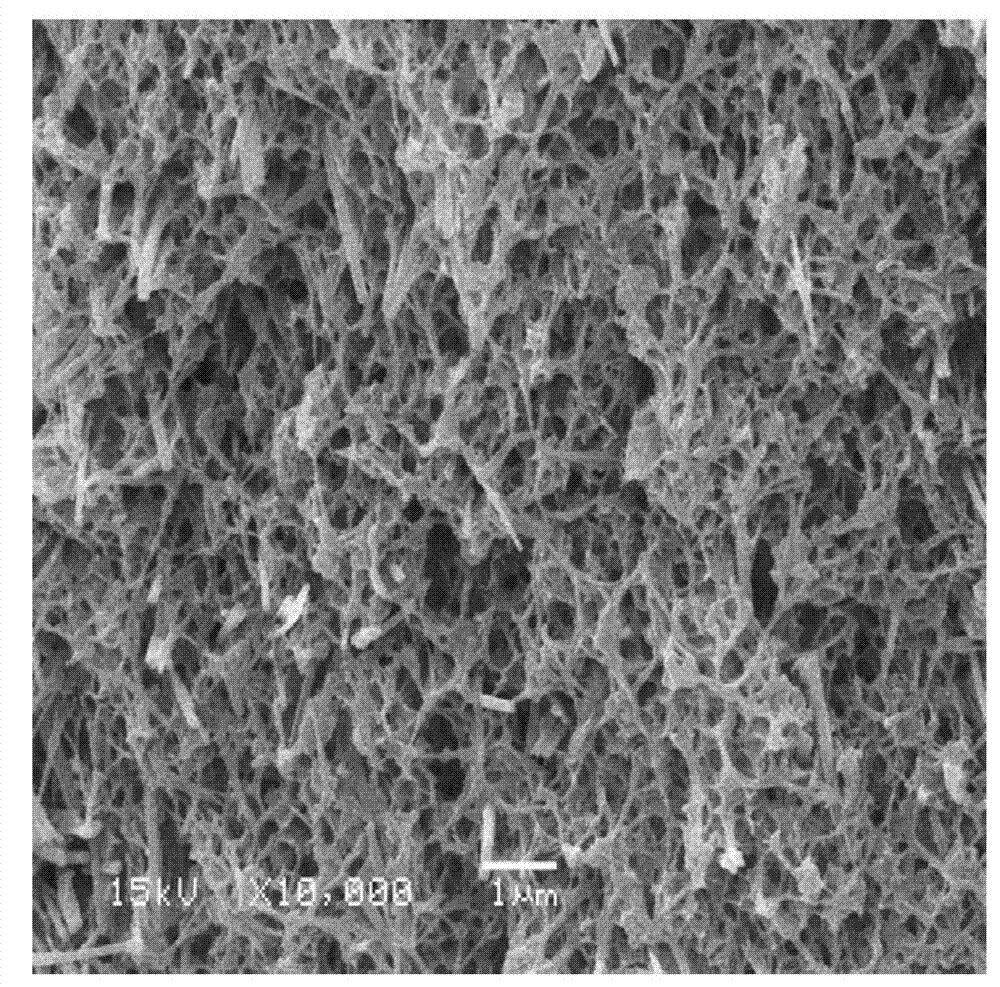

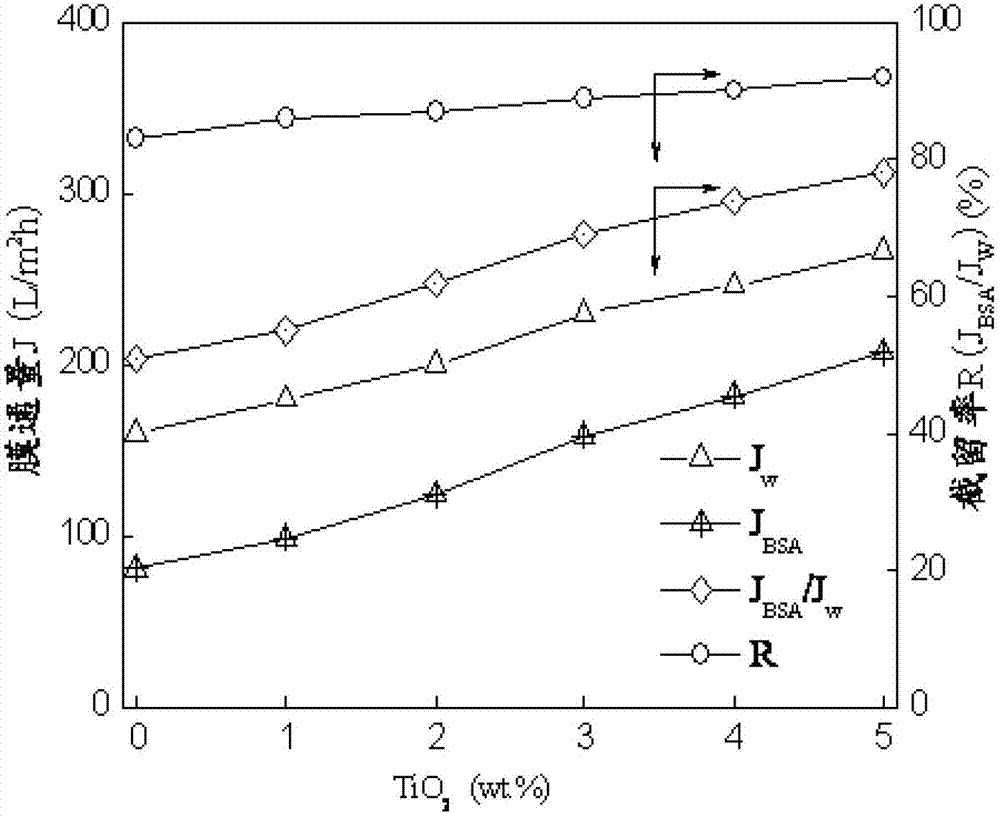

InactiveCN102728240AEasy reunionEasy to drainSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisOrganic solventNanowire

The invention relates to a titanium oxide nanowire modified polyvinylidene fluoride separation film and a preparation method of the film. The titanium oxide nanowire modified polyvinylidene fluoride separation film comprises polyvinylidene fluoride (PVDF) accounting for 18-25wt% of the total mass, organic solvent accounting for 70-80wt% of the total mass, porogen accounting for 3-5wt% of the total mass, dispersing agent accounting for 0.1-1wt% of the total mass and titanium oxide nanowire accounting for 1-5wt% of PVDF. The modified film solves the problem that the PVDF-TiO2 nanoparticles are easily agglomerated and can easily run away, and has stability and durability.

Owner:CHANGZHOU UNIV

Composite titanium dioxide photocatalyst sol coating material component and coating method thereof

InactiveCN102653639AImprove hydrophilic propertiesImprove hydrophilicityPretreated surfacesCoatingsWater wetRoom temperature

The invention discloses a composite titanium dioxide photocatalyst sol coating material component which is good in water-wet behavior in case of no light lay irritation or insufficient light lay irritation and a coating method of the composite titanium dioxide photocatalyst sol coating material component, aiming at improving the water-wet behavior of the titanium dioxide photocatalyst in case of no light lay irritation or insufficient light lay irritation, wherein the coating material which is formed by proportioning titanium dioxide photocatalyst sol and hydroxyl-containing porous metal oxide sol in proper proportion is coated on the surface of a base material, and a layer of functional coating layer is formed on the surface of the base material after the coating layer is dried at normal temperature and solidified in a heating way. Under the condition of sufficient light lay irritation, the coating layer has the chemical decomposition or degradation characteristic of the titanium dioxide photocatalyst, can decompose or degrade the organic pollutant adhered to the surface face of the base material, and further has the physical hydrophilic soil release. The coating layer is good in the water-wet behavior in case of no light lay irritation or insufficient light lay irritation, so that the dirt on the surface can be easily washed to be removed by the means that the base material is washed by water, therefore, the cleanness of the base material can be kept.

Owner:GREENCOAT TECH

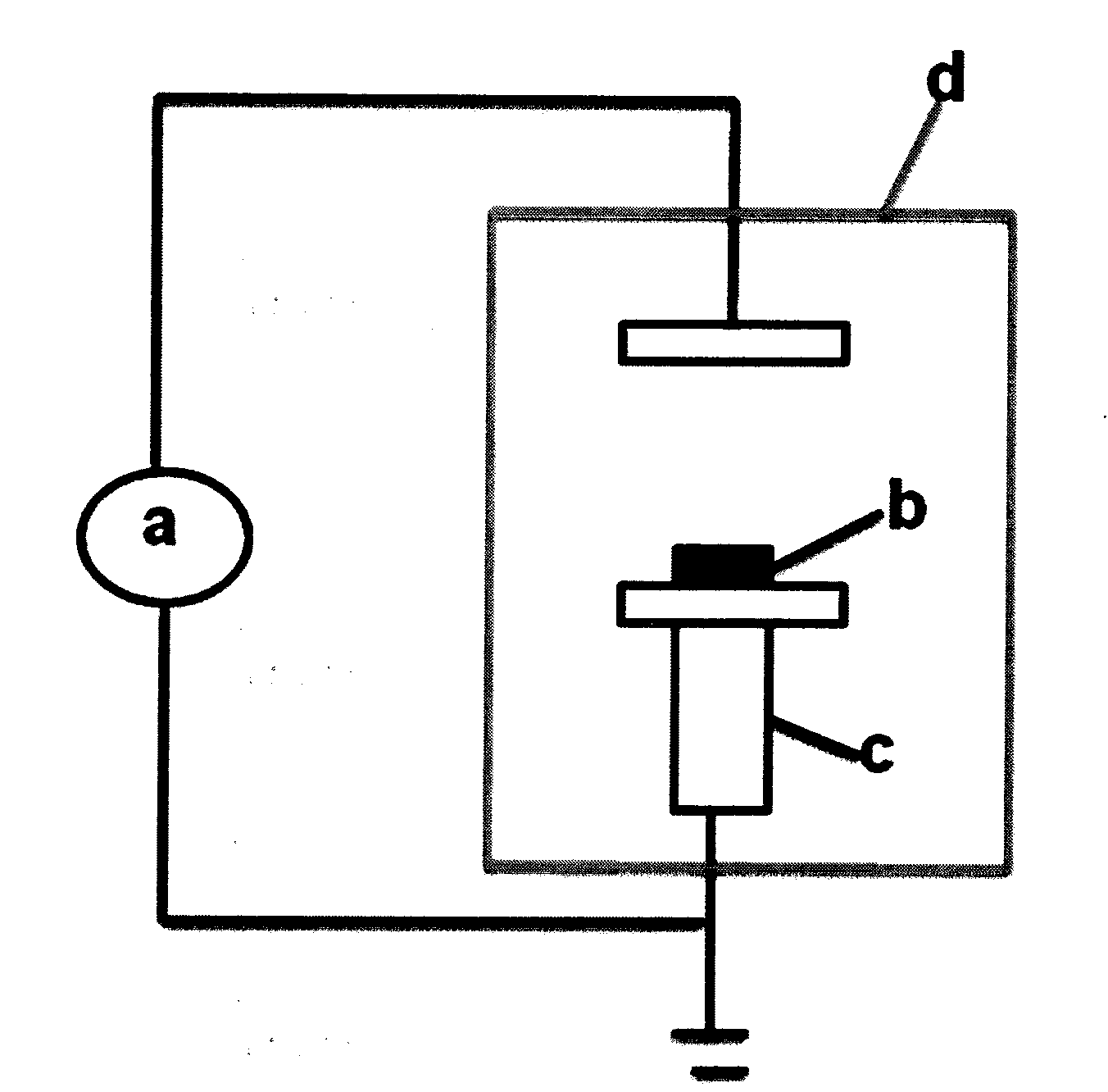

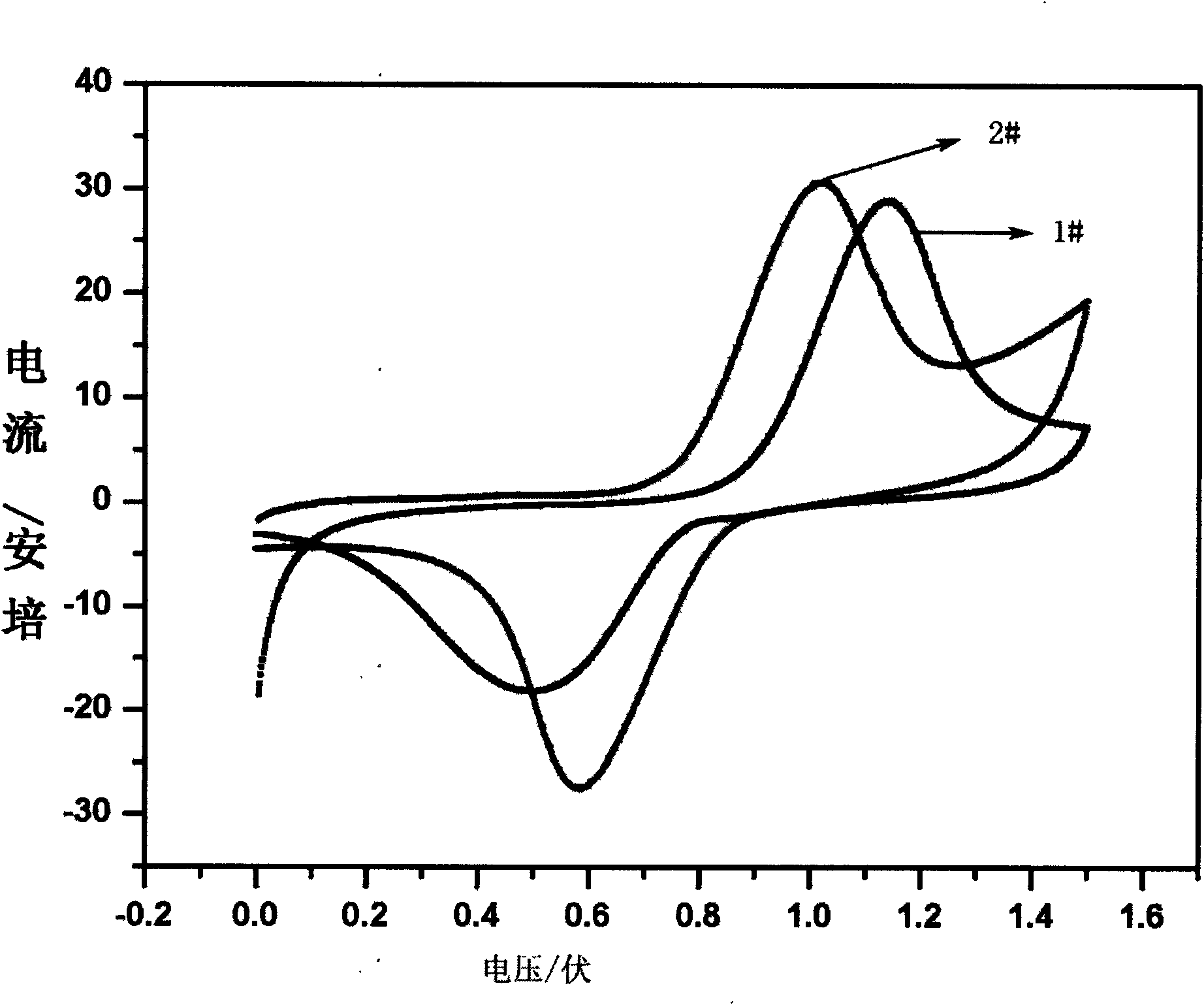

Surface modification method for raising activity of electrode material of vanadium cell

ActiveCN102723502AImprove energy storage efficiencyImprove hydrophilic propertiesCell electrodesCell fabricationElectrical polarity

The invention, relating to the field of cell manufacturing and energy storage, discloses a surface modification method for raising the activity of an electrode material of a vanadium cell, comprising the following steps: firstly cleaning the electrode material of the vanadium cell to remove surface impurities, then carrying out modification treatment of the electrode material by using plasma, reacting the gas which generates plasma with the electrode surface under ionization state to generate polar functional groups; and finally carrying out ultrasonic cleaning on the modified electrode material for 5-30 min and drying at 60-120 DEG C. According to the invention, by using the method of the invention to carry out surface modification on the electrode material of the vanadium cell, the hydrophilcity of the electrode surface is enhanced, partial polar functional groups has good catalytic influence on electrode reaction, and the energy storage efficiency of the cell is expected to increase. The method can be used for processing material surfaces with various morphologies and can keep mechanical properties and the like of material matrixes, the experiment condition are easy to control and the method has no pollution to environment. The method is efficient and environmentally friendly.

Owner:辽宁科京新材料有限公司

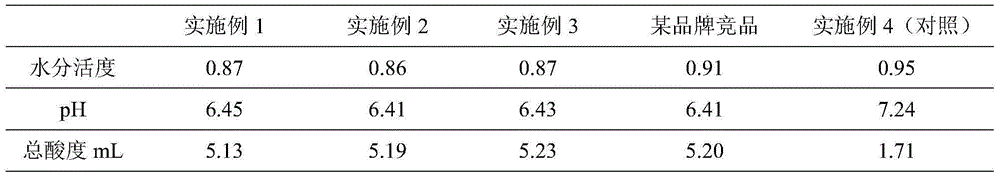

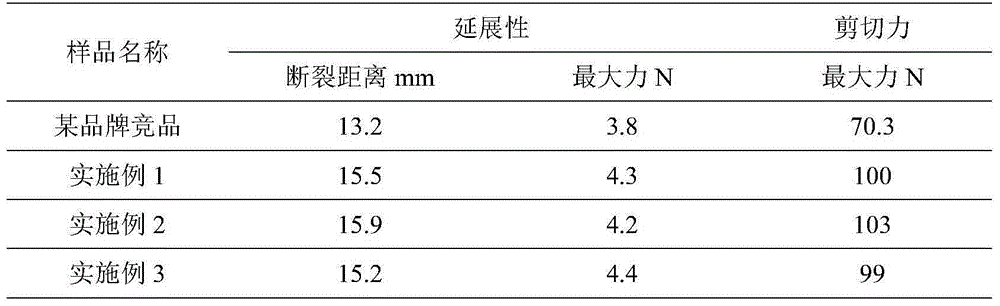

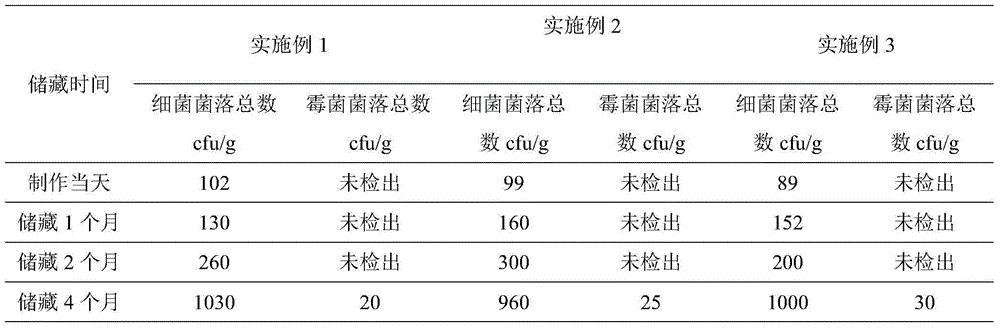

Method for preparing microwave instant taco through sour dough

ActiveCN105010463AEasy to prepareReduce energy consumptionBaking processesBakery productsNutrientExpiration date

The invention discloses a method for preparing a microwave instant taco through sour dough and belongs to the technical field of food production. According to the method, firstly, liquid sour dough paste fermented through lactobacillus plantarum is prepared; secondly, the sour dough is taken to prepare taco dough, and the taco is prepared through the steps of fermenting, cooking and the like. According to the taco prepared through the method, the product technology can be effectively simplified, the product cost can be reduced, the amount of chemical addition agents can be decreased, the taco can be stored at least for four months at the normal temperature, the shelf expiration date of the product is effectively prolonged, the aging speed of the product is reduced, and the taco has the advantages of being nutrient, health, easy to process and the like.

Owner:JIANGNAN UNIV

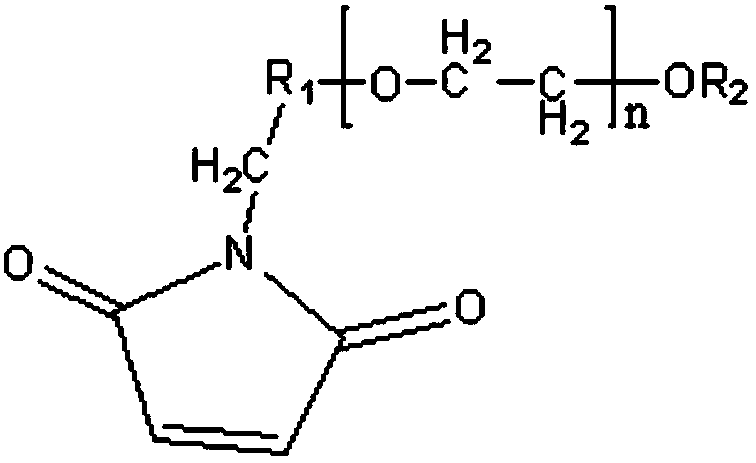

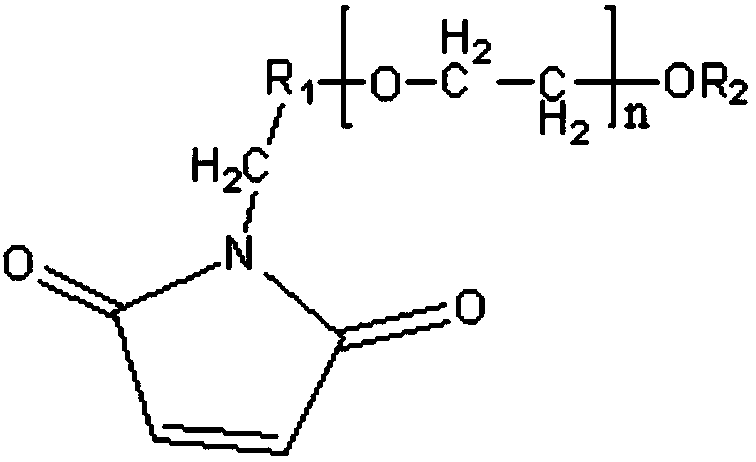

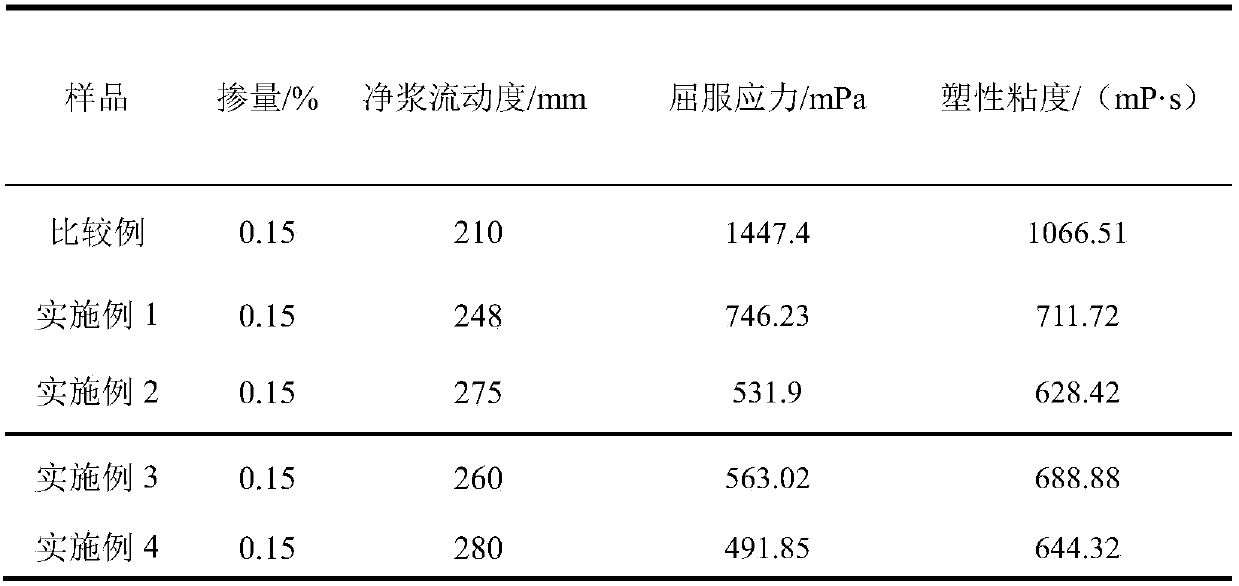

Polycarboxylic acid water reducing agent for improving rheological behavior of cement pastes and preparation method thereof

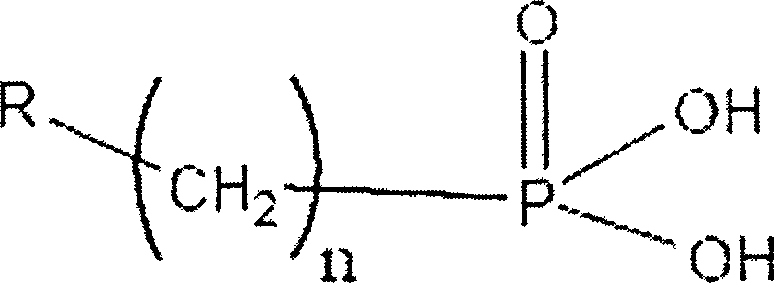

ActiveCN109627397ASignificant steric stabilization effectIncreasing the thickness(Hydroxyethyl)methacrylatePhosphate

The invention discloses a polycarboxylic acid water reducing agent for improving a rheological behavior of cement pastes. The polycarboxylic acid water reducing agent is prepared by a copolymerizationreaction of a first mixture, unsaturated polyether, hydroxyethyl methacrylate phosphate, unsaturated acid, a compound A, an initiator, a molecular weight regulator and water. The invention also discloses a preparation method of the polycarboxylic acid water reducing agent for improving the rheological behavior of cement pastes. The method comprises the following steps that an esterification product with a benzene ring is obtained by carrying out the ester exchange reaction between alkylphenol polyoxyethylene ether and unsaturated carboxylic ester; the esterification product is copolymerized with the unsaturated polyether, compound A and hydroxyethyl methacrylate phosphate to introduce a benzene ring, a phosphate group and an imide structure into branched chains of the polycarboxylic acidwater reducing agent, so that the rheological behavior of the concrete, and the stability, the fluidity and the like of the slurry can be improved.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

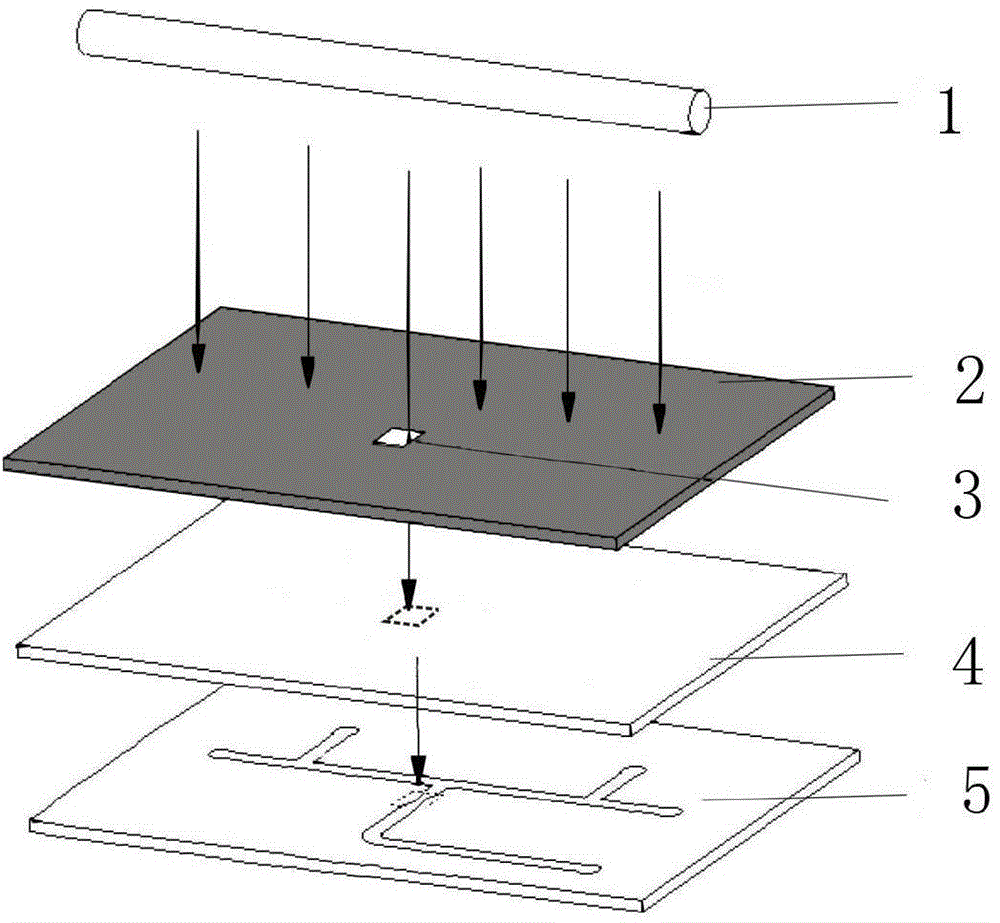

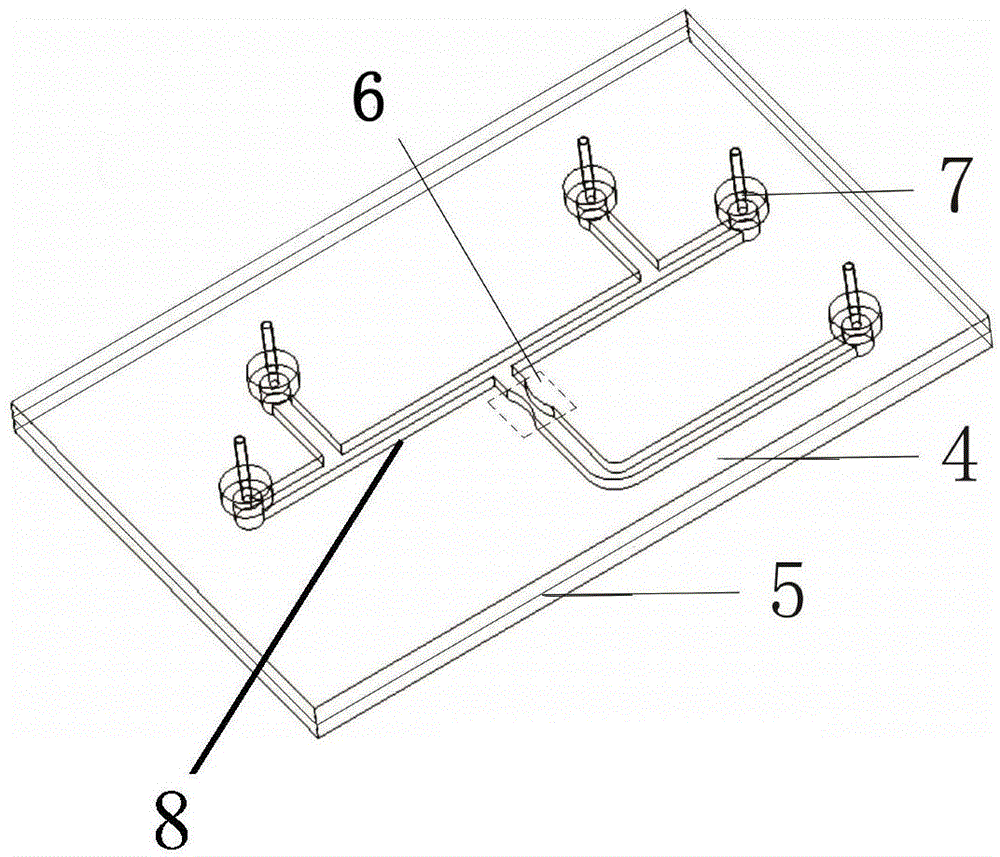

Micro-fluidic chip surface hydrophilic modification treatment method and hydrophilic surface gradient manufacture method

InactiveCN104607257AUniform film bodyImprove hydrophilic propertiesLaboratory glasswaresSurface gradientDistilled water

The invention relates to the technical field of micro-fluidic chips, and discloses a micro-fluidic chip surface hydrophilic modification treatment method and a hydrophilic surface gradient manufacture method. The micro-fluidic chip surface hydrophilic modification treatment method comprises the following steps: (1), a hydrophilic solution is prepared; (2), a mask is produced according to a micro-channel pattern requiring for hydrophilic treatment; (3), the hydrophilic solution is injected into a pipeline of a micro-fluidic chip; (4), the upper surface of the micro-fluidic chip is covered with the mask; (5), the chip is placed in a UV (ultraviolet) light curing machine to be irradiated for gradient minutes; (6), the chip is taken out of the UV light curing machine and cooled; (7), a grafting solution in the micro-channel is sucked out with negative pressure, cleaned with distilled water, soaked, washed to remove homopolymer and dried in vacuum. The UV light is adopted for modification treatment of a local area of the micro-channel or for manufacturing hydrophilic gradient, and a manufactured hydrophilic film has the advantages of uniform film body, good hydrophilic characteristic, easiness in operation and the like.

Owner:ANHUI UNIV OF SCI & TECH

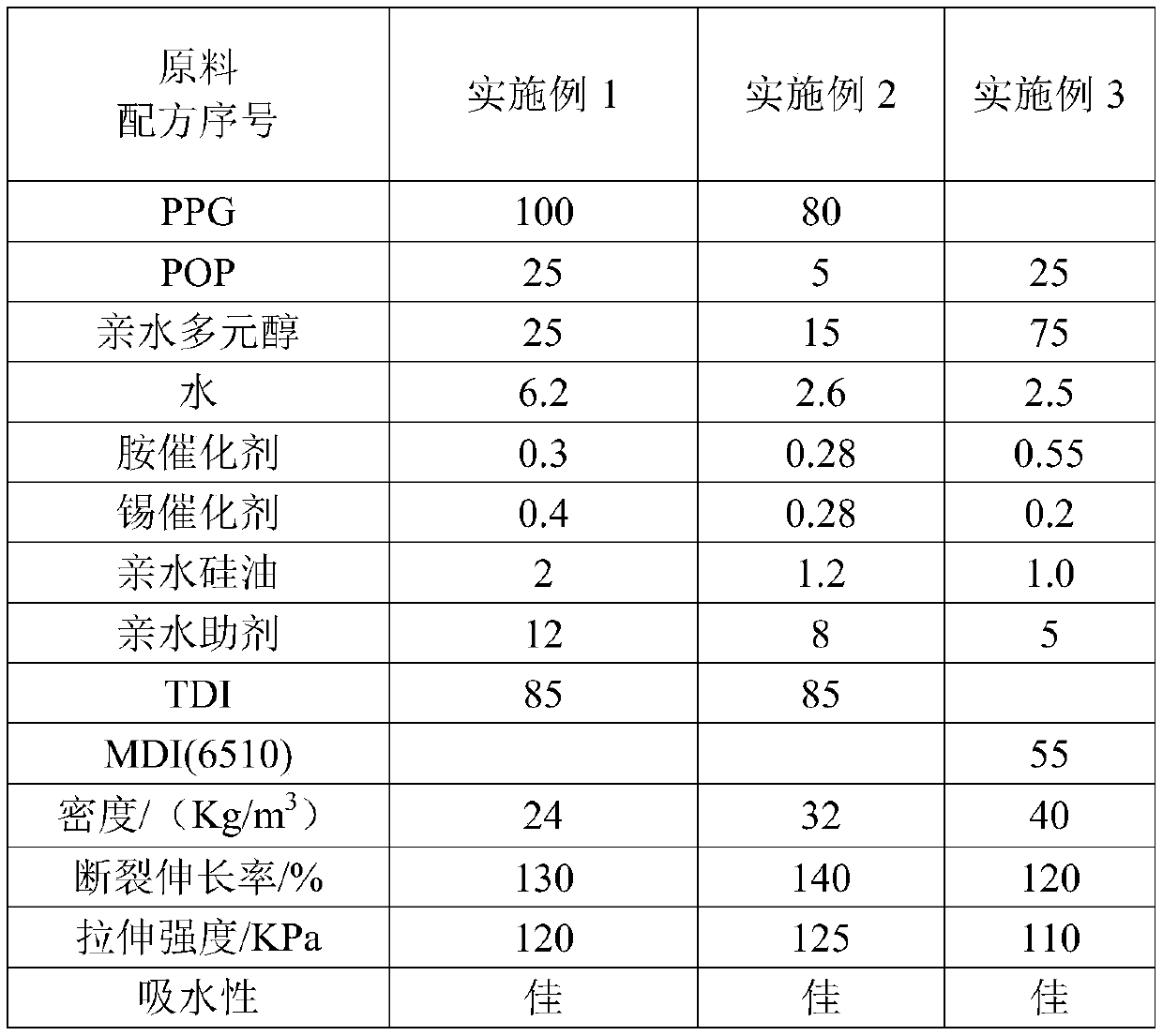

Hydrophilic sponge material and preparation method thereof

The invention belongs to the field of polyurethane flexible foam sponge materials, and particularly relates to a hydrophilic sponge material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing and foaming polyether polyol (PPG), polymer polyol (POP), hydrophilic polyol, water, hydrophilic silicone oil, a catalyst, a hydrophilic aid and diisocyanate, carrying out one-step foaming and molding, and conducting curing for one day under the condition of standard temperature and humidity to obtain the hydrophilic sponge material. The hydrophilic sponge material disclosed by the invention has the advantages of rapid water absorption, high air permeability, capability of sinking into a water bottom after saturated water absorption and the like.

Owner:江苏世丰新材料有限公司

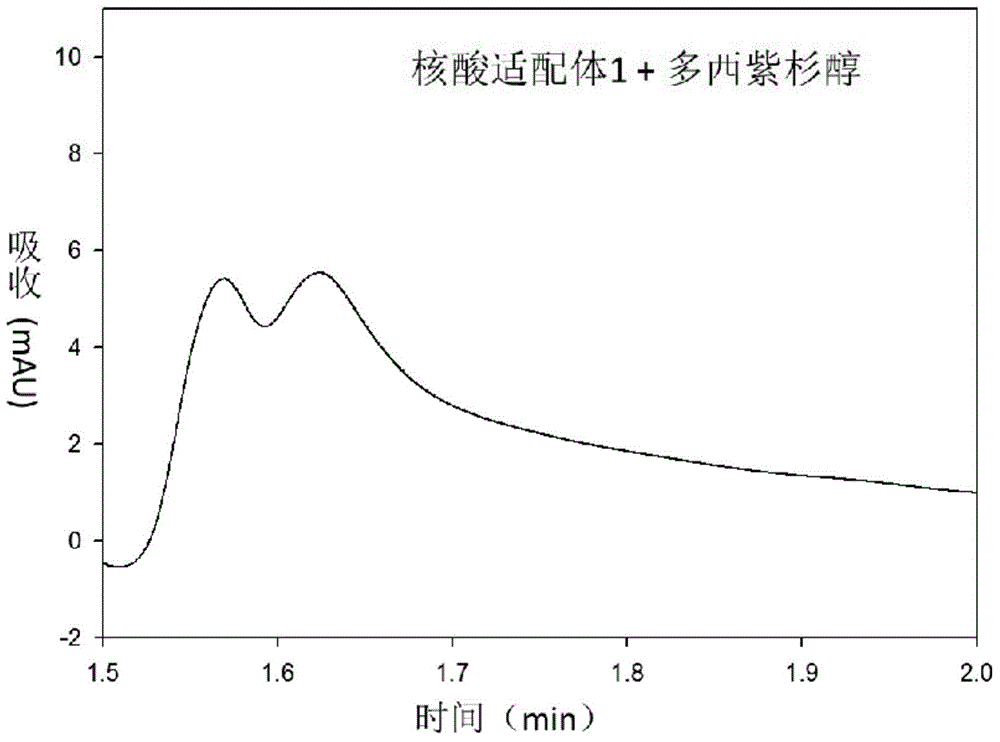

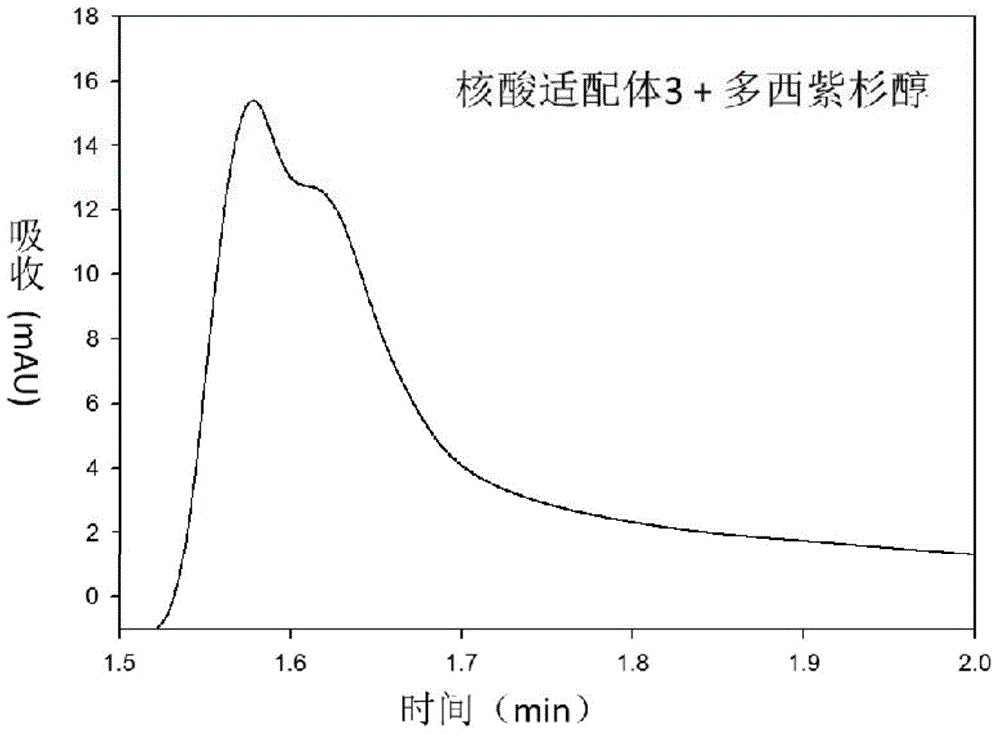

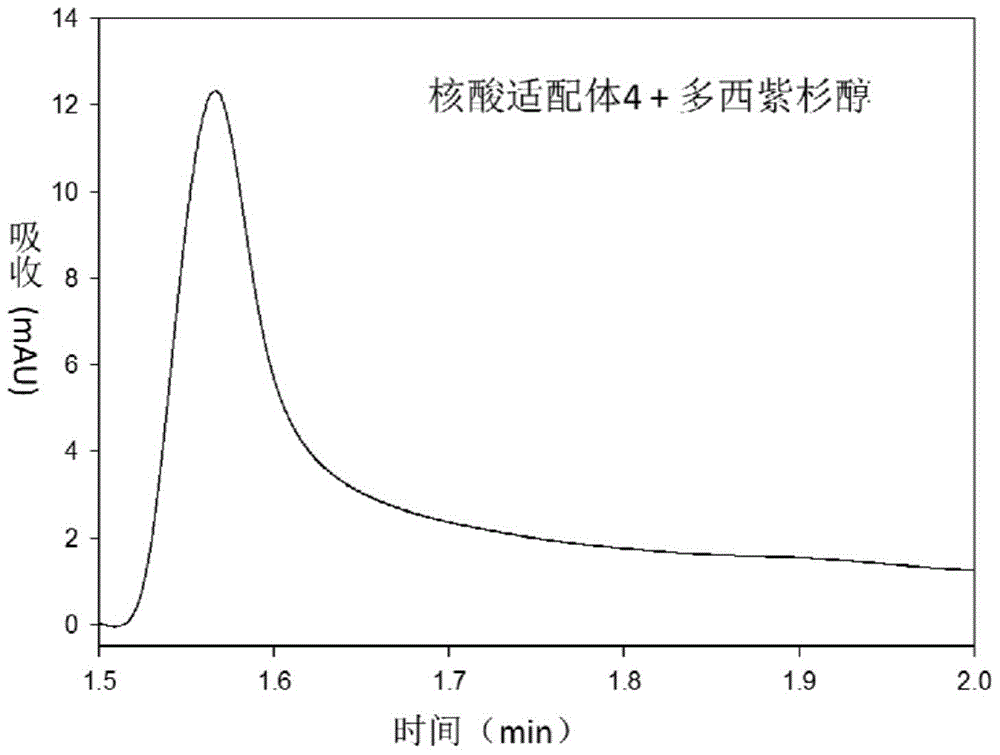

Method for screening aptamer via high performance liquid chromatography, aptamer and application

ActiveCN104480114ALow instrument requirementsUniversalOrganic active ingredientsComponent separationChromatographic columnChemistry

The invention discloses a method for screening an aptamer via a high performance liquid chromatography, the aptamer and an application. The method for screening aptamers via high performance liquid chromatography comprises the following steps: screening a nucleic acid library of aptamers combined with docetaxel specificity from a random library RS36; screening the nucleic acid library by the high performance liquid chromatography to obtain the aptamer. In the high performance liquid chromatography, the stationary phase is an octadecyl bonded silica gel chromatographic column, the moving phase adopts water-acetonitrile gradient elution, the detection wavelength is 260nm and the detector is a diode array detector. The aptamer screened according to the high performance liquid chromatography has the advantages of being bonded with high specificity and high appetency of docetaxel, being free of immunogenicity, being capable of carrying out chemical synthesis and being good in biocompatibility, small in molecular weight, stable and easy to store, and can be applied to drug carriers, drug separation and purification, and preparation of docetaxel detection probes or target probes.

Owner:HUNAN UNIV

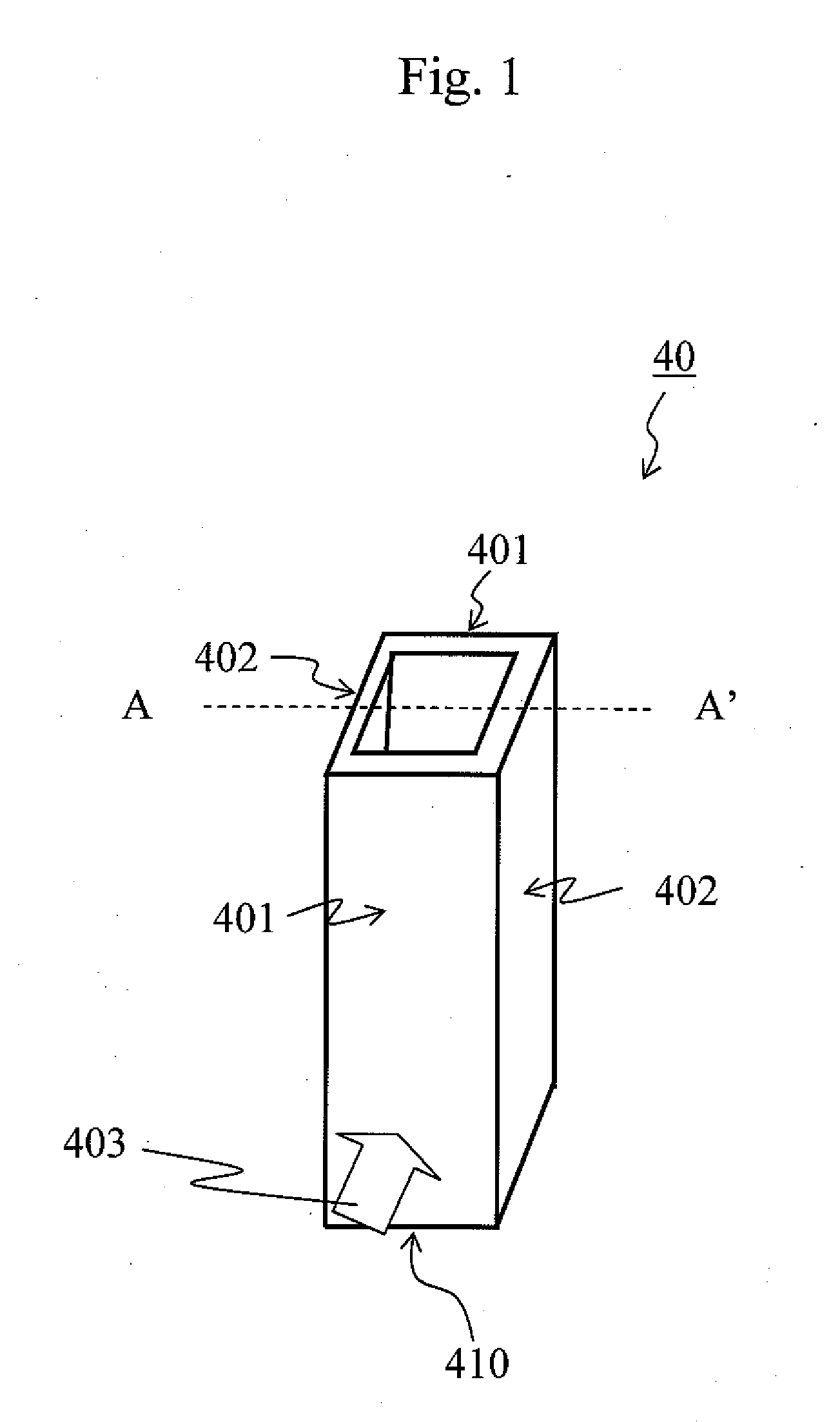

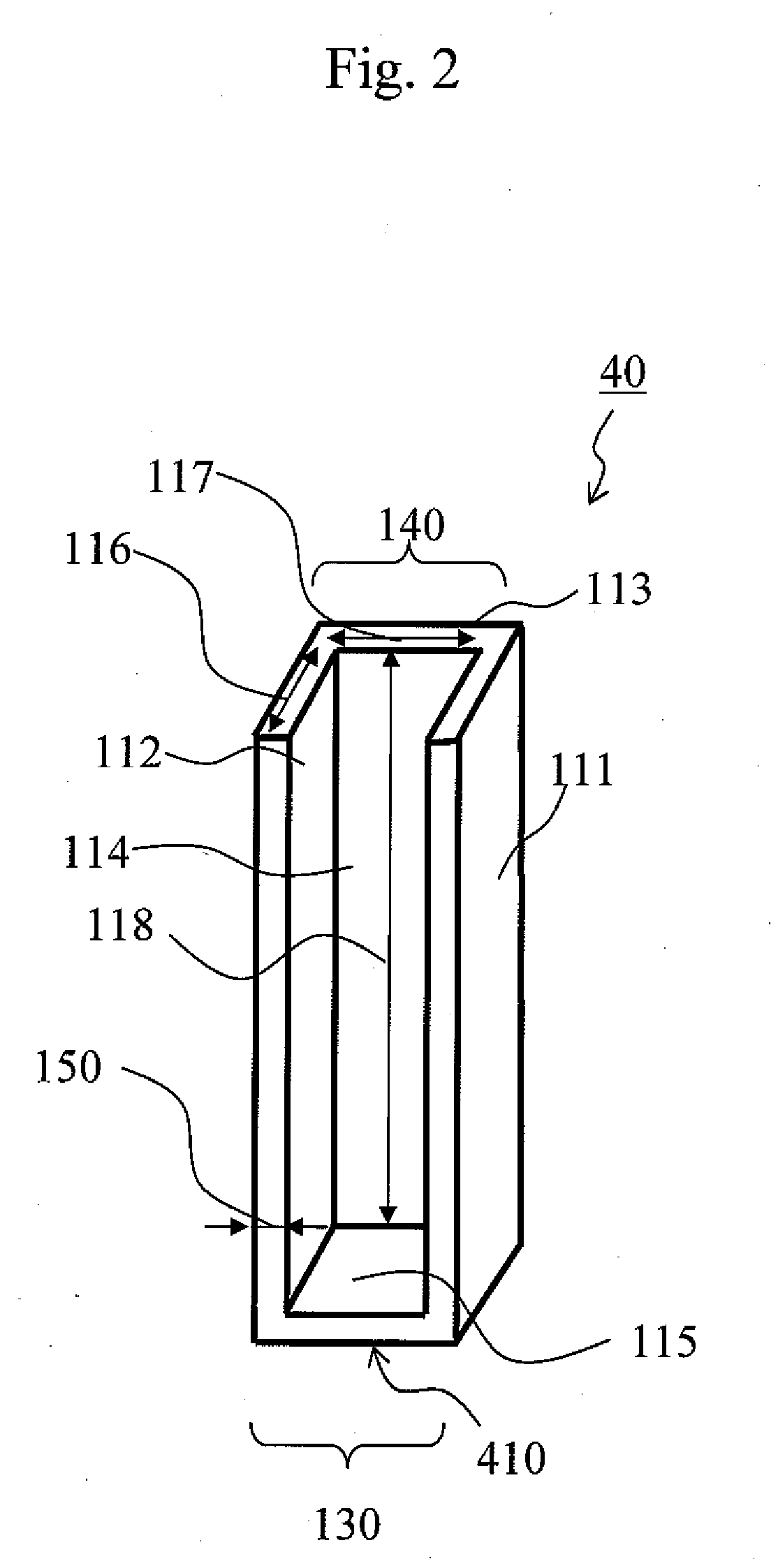

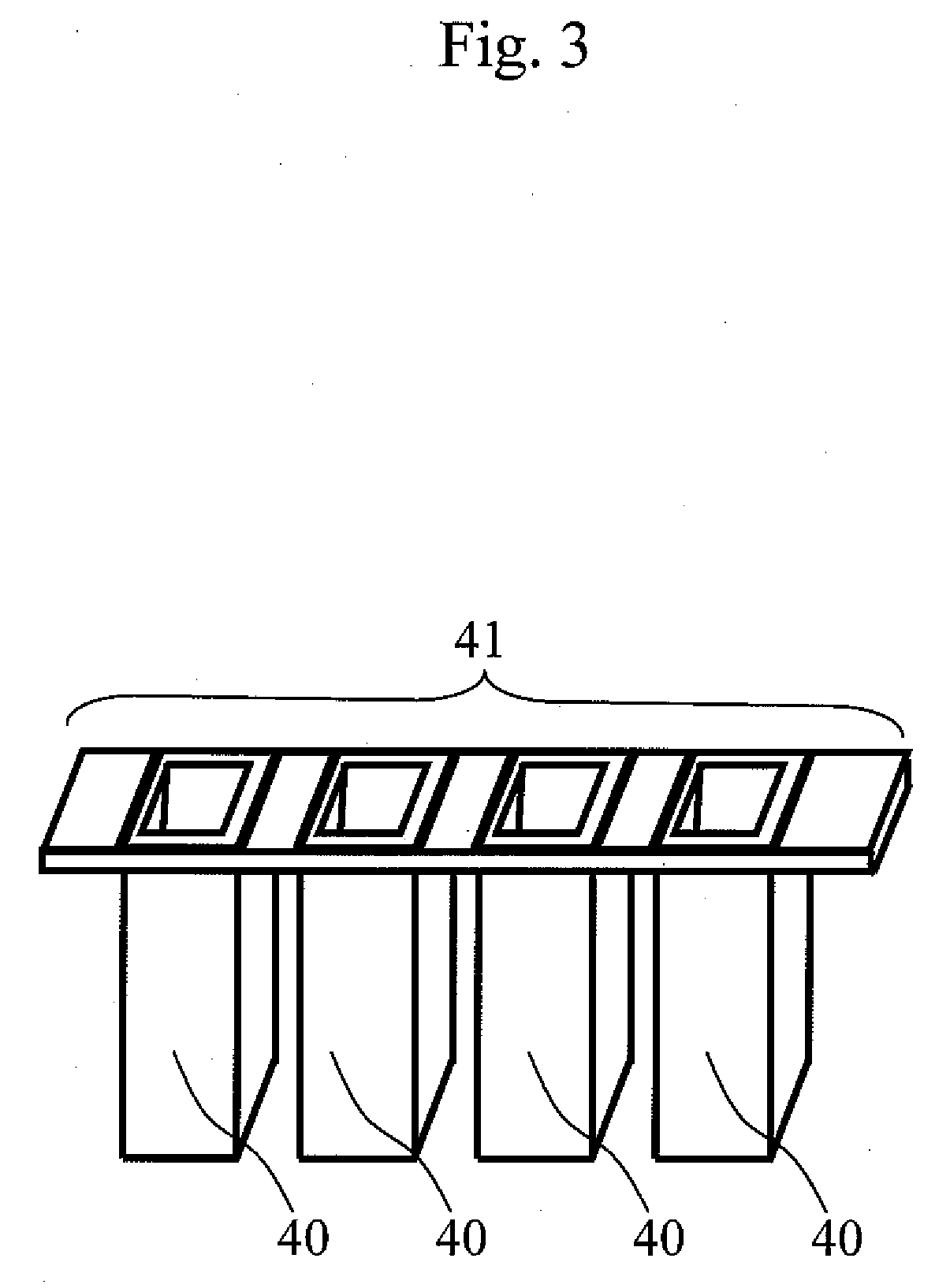

Cell Made of Polymers for Spectra Measurement and Method for Producing the Same

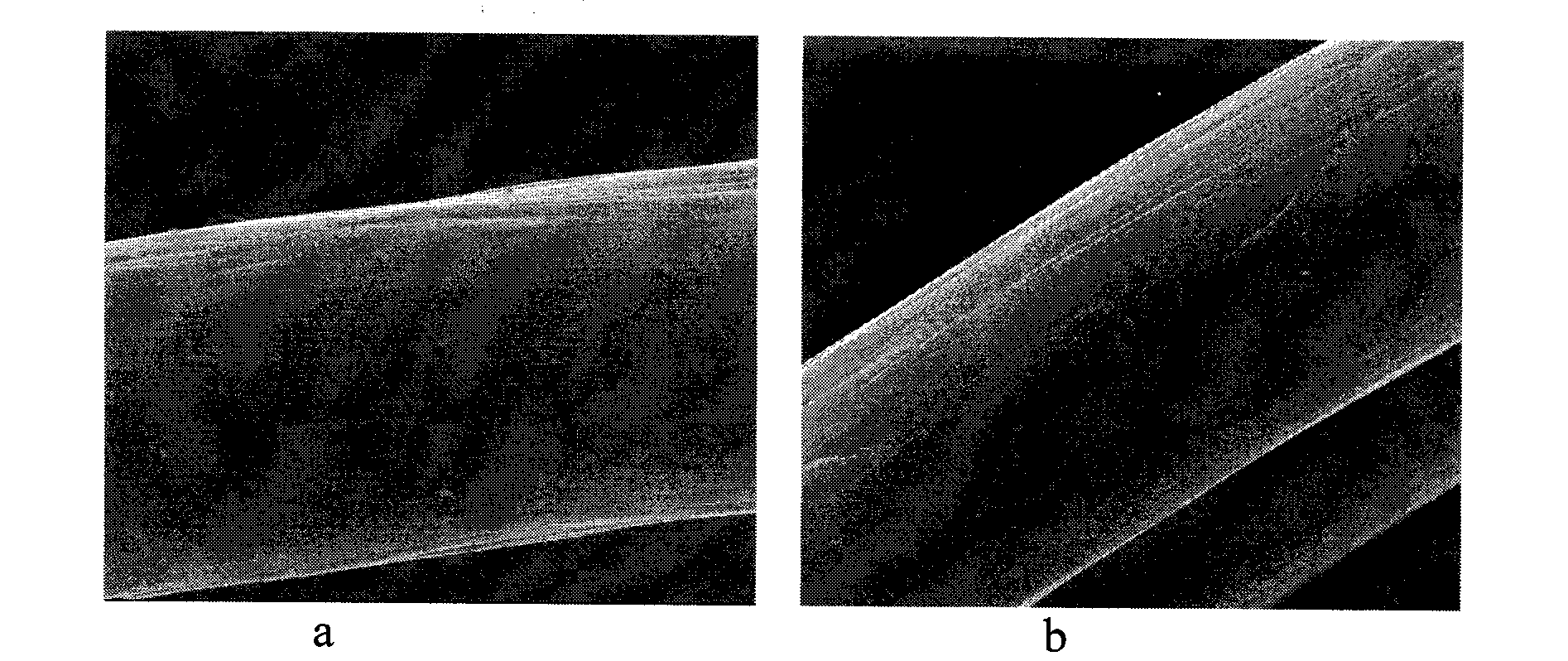

InactiveUS20090306300A1Improve surface propertiesLower contact angleMaterial analysis by optical meansLaboratory glasswaresElectric dischargePolymer resin

This invention provides a cell made of polymers for spectra measurement while inhibiting a decrease in a molecular weight of resin caused by discharge treatment and having a stable hydrophilic modified surface. The hydrophilic resin cell is prepared by providing a polymeric resin cell between the two opposing electrodes, applying an electric field to a region between the above opposing electrodes under a nitrogen atmosphere with a pressure close to the atmospheric pressure to generate an electric discharge, and exposing the cell subjected to discharge treatment with a gas including oxygen.

Owner:HITACHI HIGH-TECH CORP

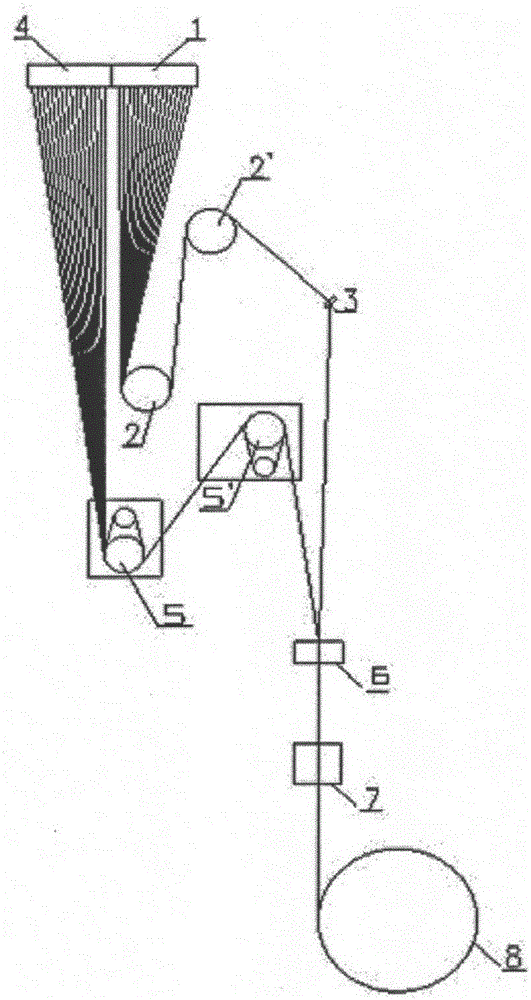

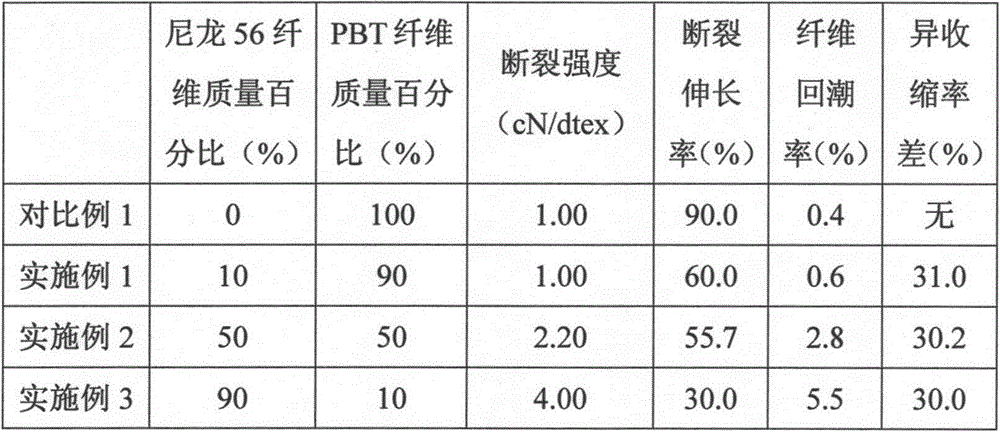

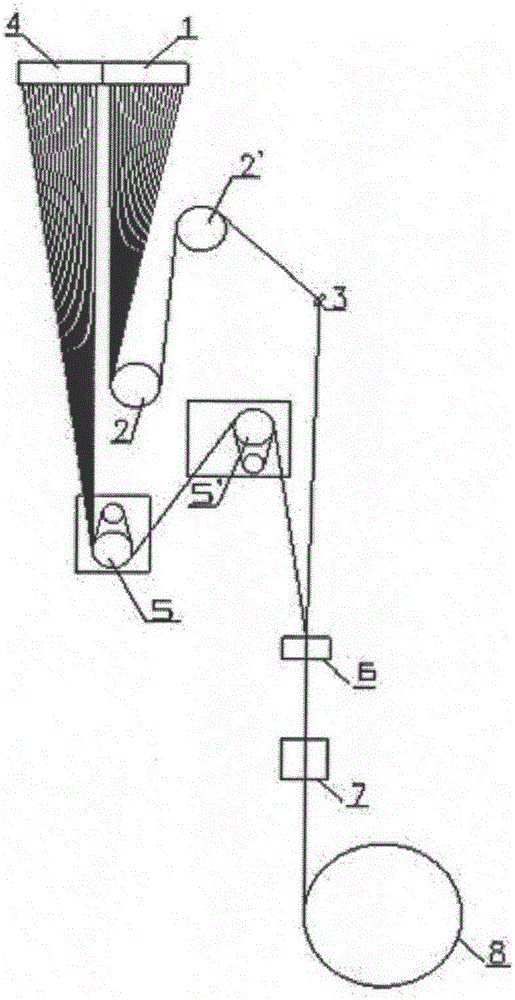

FDY/POY differential shrinkage blended filament of biomass nylon 56 fiber/PBT fiber, and preparation method thereof

InactiveCN105862166AHigh moisture regainIncrease elasticityConjugated synthetic polymer artificial filamentsFiberMaterials science

The invention discloses an FDY / POY differential shrinkage blended filament of a biomass nylon 56 fiber / PBT fiber. The FDY / POY differential shrinkage blended filament is prepared through spinning biomass nylon 56 slices and PBT slices; the biomass nylon 56 fiber is an FDY fiber and the PBT fiber is a POY fiber, or the biomass nylon 56 fiber is the POY fiber and the PBT fiber is the FDY fiber; and a difference between the boiling water shrinkage of the biomass nylon 56 fiber and the boiling water shrinkage of the PBT fiber is not smaller than 30%. The FDY / POY differential shrinkage blended filament of the biomass nylon 56 fiber / PBT fiber has the advantages of fine natural curling surface and greatly improved hydrophilicity, and can be used in development of cotton-like and silk-like textiles.

Owner:DONGHUA UNIV +2

Compound electrostatic spun diaphragm material with added dopamine modified aluminum sulfate

InactiveCN106328388AIncrease liquid absorptionImprove thermal stabilityHybrid capacitor separatorsHybrid/EDL manufacturePorosityPolymethyl methacrylate

The invention discloses a compound electrostatic spun diaphragm material with added dopamine modified aluminum sulfate. The compound electrostatic spun diaphragm material is made from, by weight, 80-83 parts of polyvinylidene fluoride, 20-22 parts of polymethyl methacrylate, an appropriate amount of DMF, 2-3 parts of nanometer boehmite, 0.8-1 part of silane coupling agent KH550, an appropriate amount of deionized water, an appropriate amount of trihydroxymethyl aminomethane, 2-3 parts of dopamine and 1-1.3 parts of aluminum sulfate. The dopamine solution reacts with aluminum sulfate, dopamine aggregates on the surface of aluminum sulfate, small and compact particles are formed on the surface of the aluminum sulfate, in this way, the porosity of the diaphragm is increased, a good hydrophilic property is achieved, and imbibing efficiency is further improved. The made diaphragm material has rich pore canals, conductive ions pass through the diaphragm material easily and especially transfer under high-magnification charging and discharging conditions, and the high-property superconductor diaphragm material is obtained.

Owner:ANHUI JIANGWEI PRECISION IND

Biodegradable spinning material and preparation method and application thereof

ActiveCN111733475AImprove spinning performanceHigh molecular weightBio-packagingMonocomponent polyesters artificial filamentEmulsionAnti bacterial

The invention provides a biodegradable spinning material and a preparation method and application thereof and belongs to the technical field of biodegradable materials. The biodegradable spinning material comprises the following preparation raw materials including, by mass, 80-93 parts of chemical-modified PBAT (Poly(butylene adipate terephthalate)), 1-8 parts of PCL (polycaprolactone), 0.5-2 parts of silver nanowire emulsion, 3-11 parts of functional master batch and 0.05-0.2 part of degradation balancing agent, wherein the weight-average molecular weight of the chemical-modified PBAT is 16000 to 38000, and the mass content of silver nanowires in the silver nanowire emulsion is 45% to 60%. The spinning material provided by the invention has the good spinnability and the good strength and is biodegradable, the degradation process can be effectively controlled according to the using requirements of people, a product obtained through spinning of the spinning material is good in breathability and anti-bacterial property, and a certain blocking effect is achieved in terms of clothing materials.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

Preparation method for diethylene glycol mono-methyl ether composition of beta-cyclodextrin based naphthenic acid ester

InactiveCN104789283AHas a corrosion inhibiting effectLowering the freezing pointLiquid carbonaceous fuelsFuel additivesDiethylene glycolCyclodextrin

The invention relates to a diethylene glycol mono-methyl ether composition of beta-cyclodextrin based naphthenic acid ester. The composition is obtained by firstly reacting beta-cyclodextrin with naphthenic acid to obtain beta-cyclodextrin based naphthenic acid ester, then reacting the beta-cyclodextrin based naphthenic acid ester with diethylene glycol mono-methyl ether to obtain the diethylene glycol mono-methyl ether composition of beta-cyclodextrin based naphthenic acid ester. The technical scheme includes: weighing 17.9g of naphthenic acid and 28.4g of beta-cyclodextrin to carry out reaction in the N, N-dimethylformamide solvent at 80DEG C for 10h, then conducting washing, stratification and drying to obtain the beta-cyclodextrin based naphthenic acid ester, subjecting the beta-cyclodextrin based naphthenic acid ester and diethylene glycol mono-methyl ether of the same mass to ultrasonic oscillation reaction for 4h at 60DEG C, thus obtaining the diethylene glycol mono-methyl ether composition of beta-cyclodextrin based naphthenic acid ester. The preparation method of the diethylene glycol mono-methyl ether composition anti-icing agent of beta-cyclodextrin based naphthenic acid ester is simple, and has excellent anti-icing effect.

Owner:JILIN INST OF CHEM TECH

Chewing gum base and chewing gum compositions

A chewing gum base essentially free of non-silica fillers, comprising high molecular weight polyisobutylene, optionally amorphous silica and polyvinylacetate and powdered lecithin present in the chewing gum composition and optionally spray-dried flavor in the chewing gum composition.

Owner:WM WRIGLEY JR CO

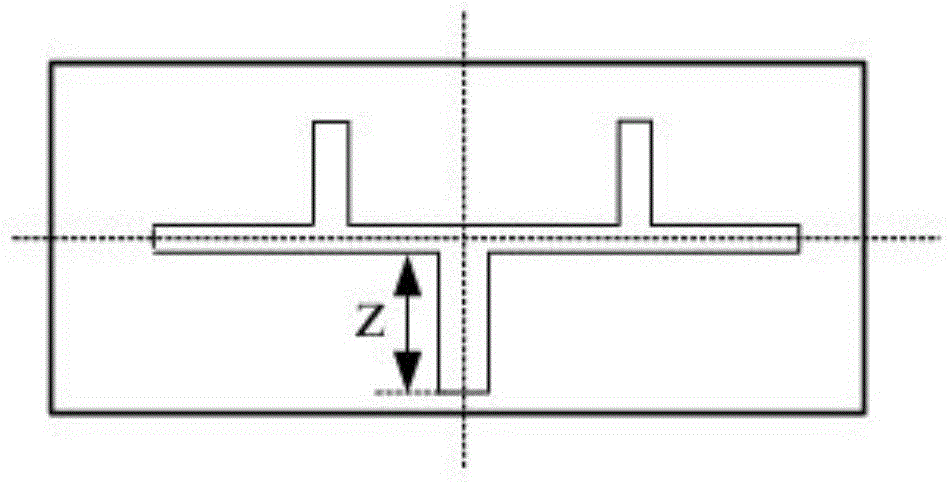

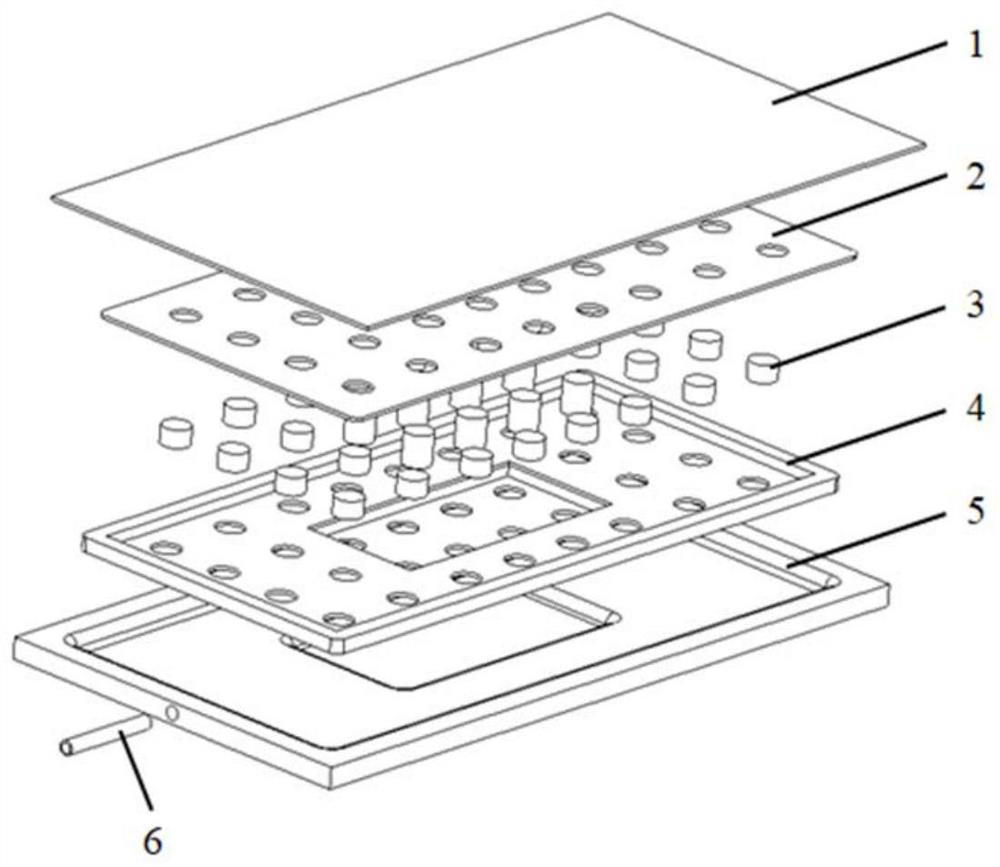

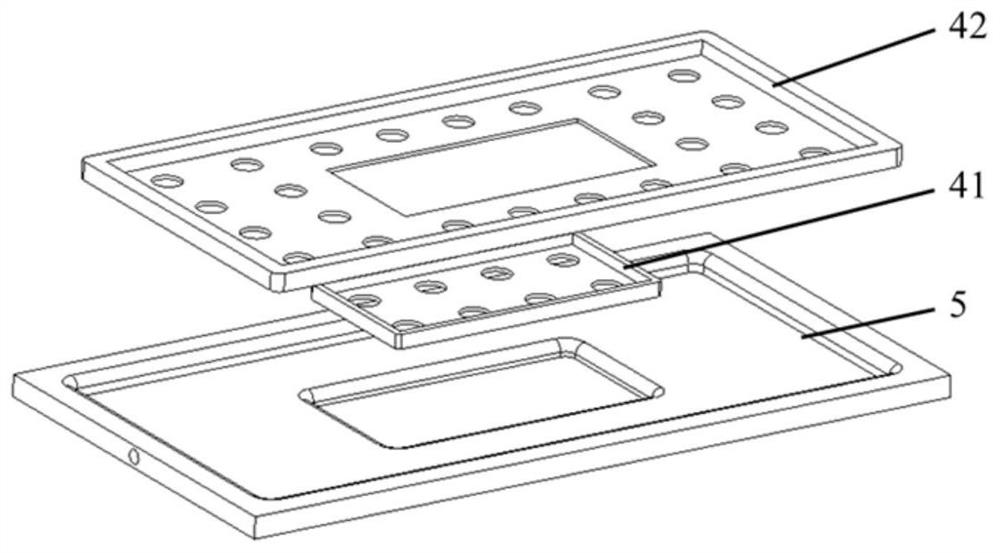

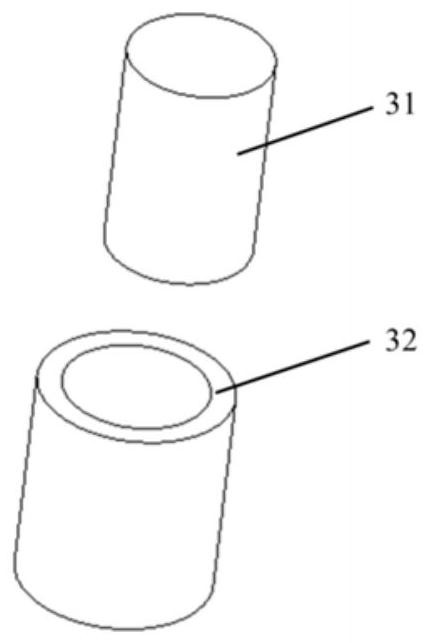

Vapor chamber with gradient wick structure and preparation method thereof

PendingCN114025562AReduce thermal contact resistanceImprove performanceIndirect heat exchangersModifications using liquid coolingHeat flowPorous medium

The invention discloses a vapor chamber with a gradient wick structure and a preparation method of the vapor chamber. The vapor chamber comprises an upper shell plate, a condensation end wick, a support column, an evaporation end wick, a lower shell plate and a liquid injection pipe, wherein the inner surface of the lower shell plate can be a plane or a stepped concave surface, the inner surface of the lower shell plate can be divided into different areas according to the relative positions of the lower shell plate and a heat source contact area, the evaporation end wick is a composite porous medium with different capillary apertures and porosities, and the capillary apertures and the porosities change along with the change of the positions of the different areas. Therefore, a wick structure with gradient characteristics is formed. The effective capillary aperture, porosity and the like of the wick are regulated and controlled, the wick structure with large capillary driving force, high permeability and small flow resistance is prepared, and the vapor chamber prepared on the basis of the wick structure has the advantages of large heat transfer capacity, high heat transfer efficiency, high inverse gravity performance, high reliability and the like; and the heat dissipation requirement of electronic equipment with high heat flux density can be met.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

Natural anticorrosive natural stone paint

InactiveCN107674541AImprove water resistanceImprove thermal stabilityAntifouling/underwater paintsCellulose coatingsCelluloseNatural stone

The invention discloses a natural anticorrosive natural stone paint which comprises the following raw materials in parts by weight: 35-45 parts of natural broken stone, 10-16 parts of modified polyurethane emulsion, 5-9 parts of cellulose, 5-7 parts of thickener, 2-3 parts of antifreezing agent, 1-3 parts of mildewproof agent, 1-3 parts of surfactant, 0.1-0.3 part of propylene glycol monobutyl ether, 0.04-0.07 part of dipentene pine oil and 0.1-0.2 part of defoaming agent. The natural stone paint has favorable corrosion resistance, favorable water resistance, favorable lubricating properties,favorable suspension properties and favorable mechanical properties.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

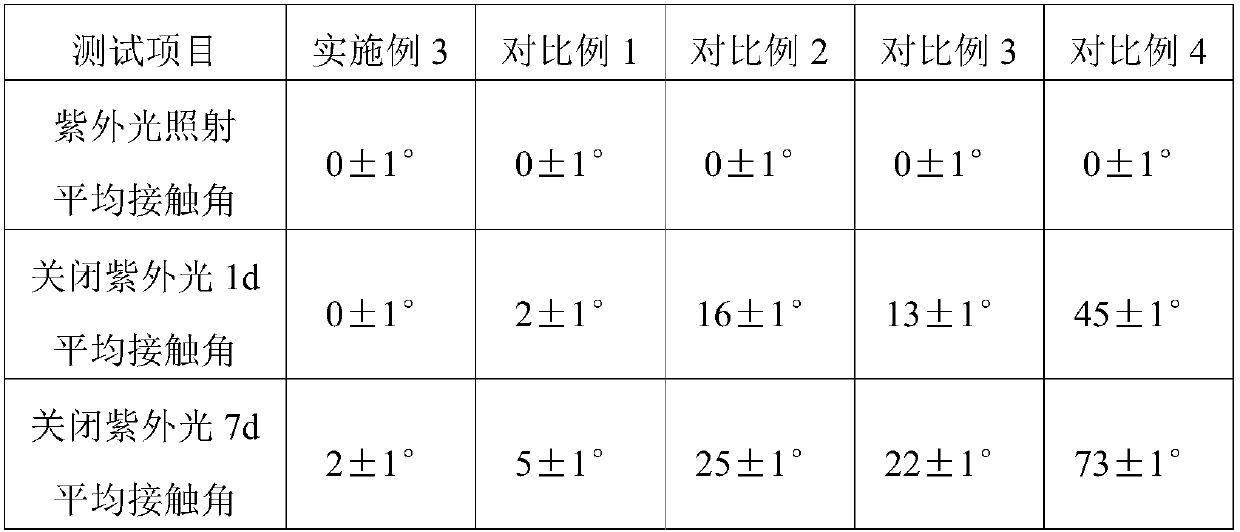

Surface-hydroxylation mesoporous SiO2-TiO compound self-cleaning coating layer and preparation method thereof

ActiveCN107858024AIncrease surface polarityIncrease polarityAntifouling/underwater paintsPaints with biocidesCoated surfaceReactive site

The invention belongs to the technical field of self-cleaning coating layers and specifically relates to a surface-hydroxylation mesoporous SiO2-TiO compound self-cleaning coating layer and a preparation method thereof. The preparation method disclosed by the invention comprises the steps: firstly, respectively preparing SiO2 sol and TiO2 sol; then roasting to obtain a mesoporous SiO2 film and utilizing a dipping-pulling method to cover a layer of TiO2 on the surface of the mesoporous SiO2 film and roasting to prepare a mesoporous SiO2-TiO2 compound coating layer; finally, performing hydrogenperoxide hydroxylation treatment to prepare the surface-hydroxylation mesoporous SiO2-TiO2 compound self-cleaning coating layer. According to the preparation method disclosed by the invention, the hydroxylation treatment on the surface of the self-cleaning coating layer makes surface polarity of the compound self-cleaning coating layer be enhanced and surface hydrophilicity be improved; mesoporesare introduced into, so that the surface roughness of the coating layer is increased to enhance the surface hydrophilicity of the coating layer; meanwhile, more TiO2 active sites are exposed, so thatsurface wettability of the compound self-cleaning coating layer disclosed by the invention is obviously improved, and the compound self-cleaning coating layer can still has good hydrophilic property under the situation without ultraviolet irradiation.

Owner:哈尔滨新干线轨道交通科技有限公司

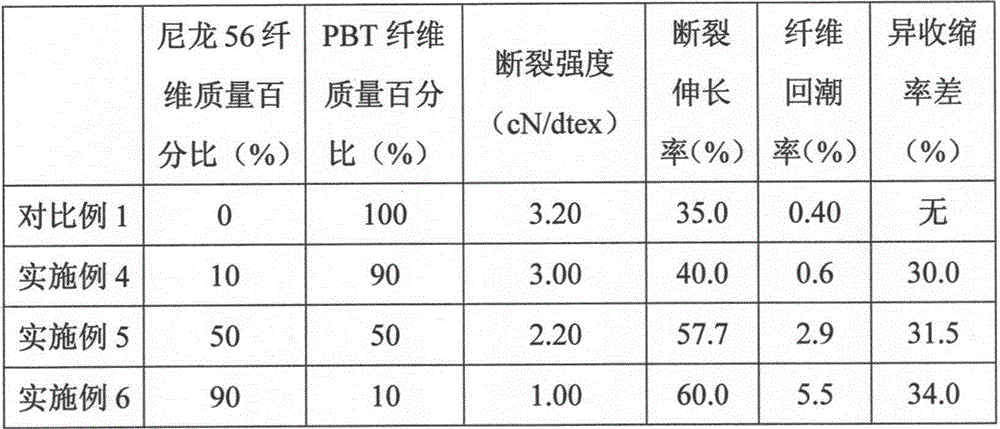

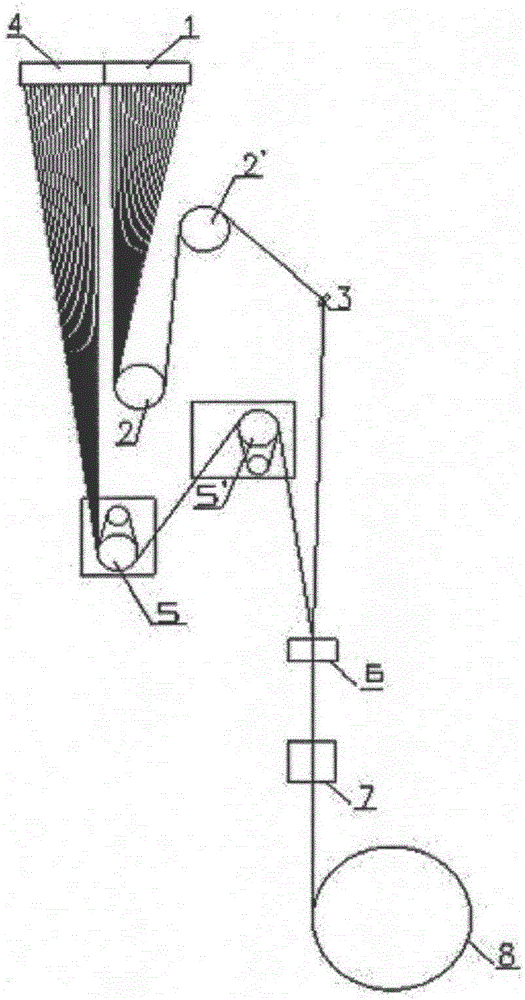

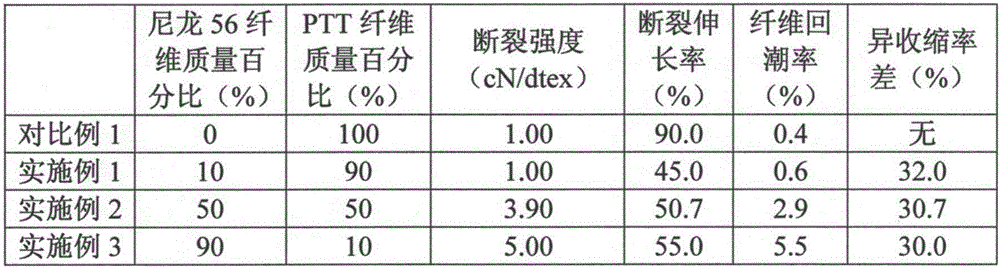

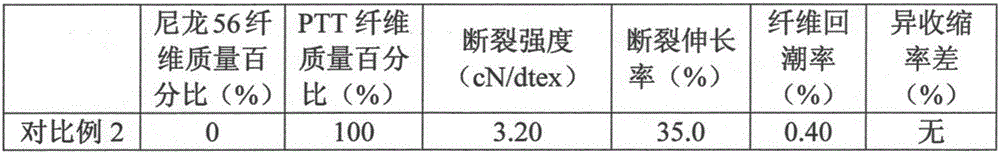

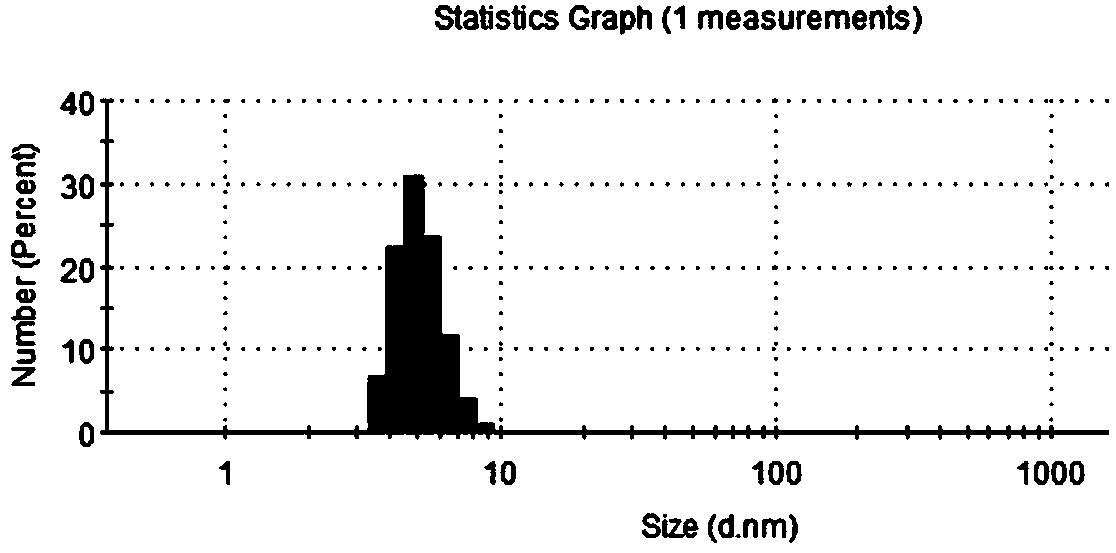

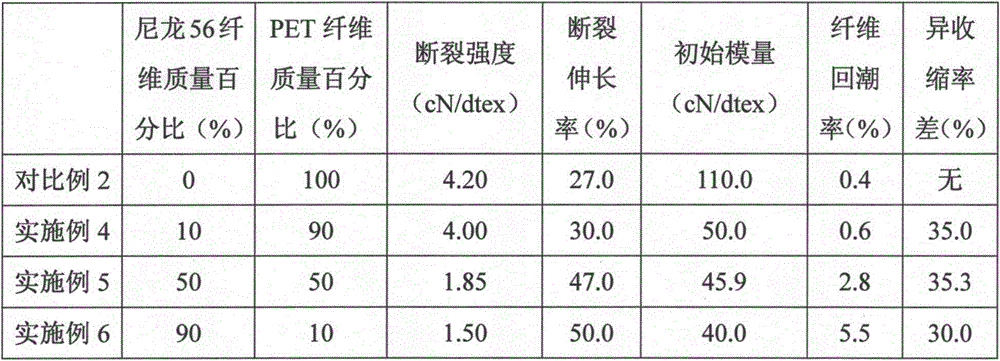

FDY/POY (fully drawn yarn/ partially oriented yarn) differential-shrinkage combined yarn prepared from biomass nylon 56 fibers/PTT (polytrimethylene terephthalate) fibers and preparation method of FDY/POY differential-shrinkage combined yarn

InactiveCN105714407AGood hydrophilic propertiesImproved hydrophilic propertiesConjugated synthetic polymer artificial filamentsYarnPolyethylene terephthalate

The invention discloses FDY / POY (fully drawn yarn / partially oriented yarn) differential-shrinkage combined yarn prepared from biomass nylon 56 fibers / PTT (polytrimethylene terephthalate) fibers. The FDY / POY differential-shrinkage combined yarn is characterized by being prepared from biomass nylon 56 chips and PTT chips through spinning; the biomass nylon 56 fibers are FDY fibers and the PTT fibers are POY fibers, or, the biomass nylon 56 fibers are POY fibers and the PTT fibers are FDY fibers; the difference of the boiling water shrinkage rate of the biomass nylon 56 fibers and the boiling water shrinkage rate of the PTT fibers is not lower than 20%. According to the FDY / POY differential-shrinkage combined yarn prepared from the biomass nylon 56 fibers / PTT fibers, the tow surface is slightly and naturally crimped, the fiber hydrophilicity is improved, and the combined yarn can be applied to the development of imitated cotton and imitated silk textiles.

Owner:DONGHUA UNIV +2

Anti-glare and anti-fogging glass as well as surface treatment fluid thereof and preparation method thereof

The invention provides anti-glare and anti-fogging glass as well as surface treatment fluid thereof and a preparation method thereof. The surface treatment fluid for the anti-glare and anti-fogging glass is prepared from the following components: ethyl orthosilicate, amino acid, water and alcohol, wherein the mass ratio of ethyl orthosilicate to amino acid to the water to the alcohol is equal to 1to (0.01-0.05) to (8-20) to (0.5-3); the surface treatment fluid for the anti-glare and anti-fogging glass is obtained by mixing ethyl orthosilicate, amino acid, the water and the alcohol, and then stirring for carrying out a reaction. By adopting the technical scheme, a water film formed on the surface of the anti-glare and anti-fogging glass has an anti-reflection effect, so that the anti-glareeffect of the display screen glass can be further improved; furthermore, based on a hydrophilic principle, the water vapor forms the water film on the surface of the glass instead of condensing intodewdrops, so that the condensation problem is fundamentally solved; furthermore, the preparation process is environmentally friendly.

Owner:深圳市格络新材科技有限公司

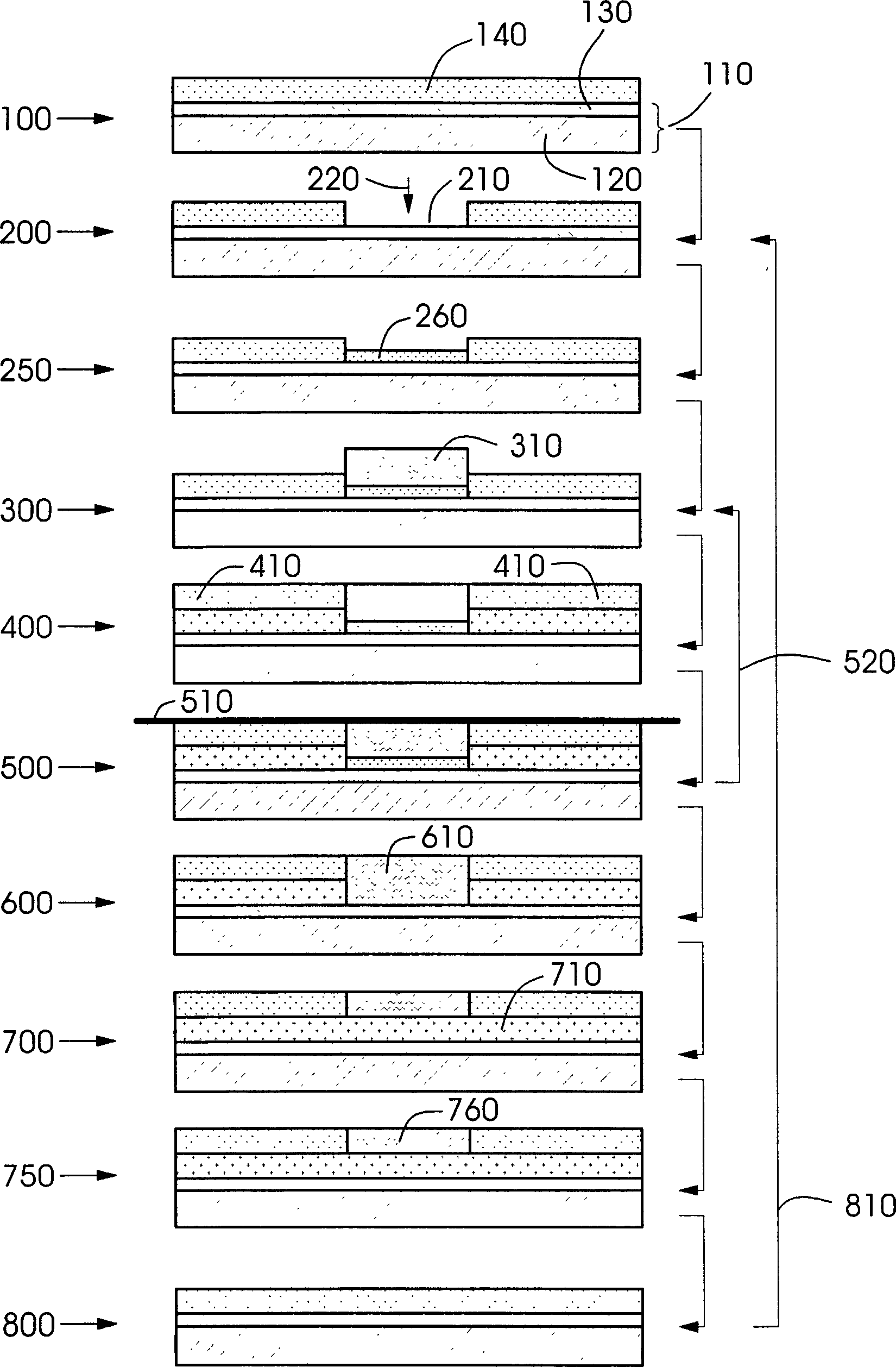

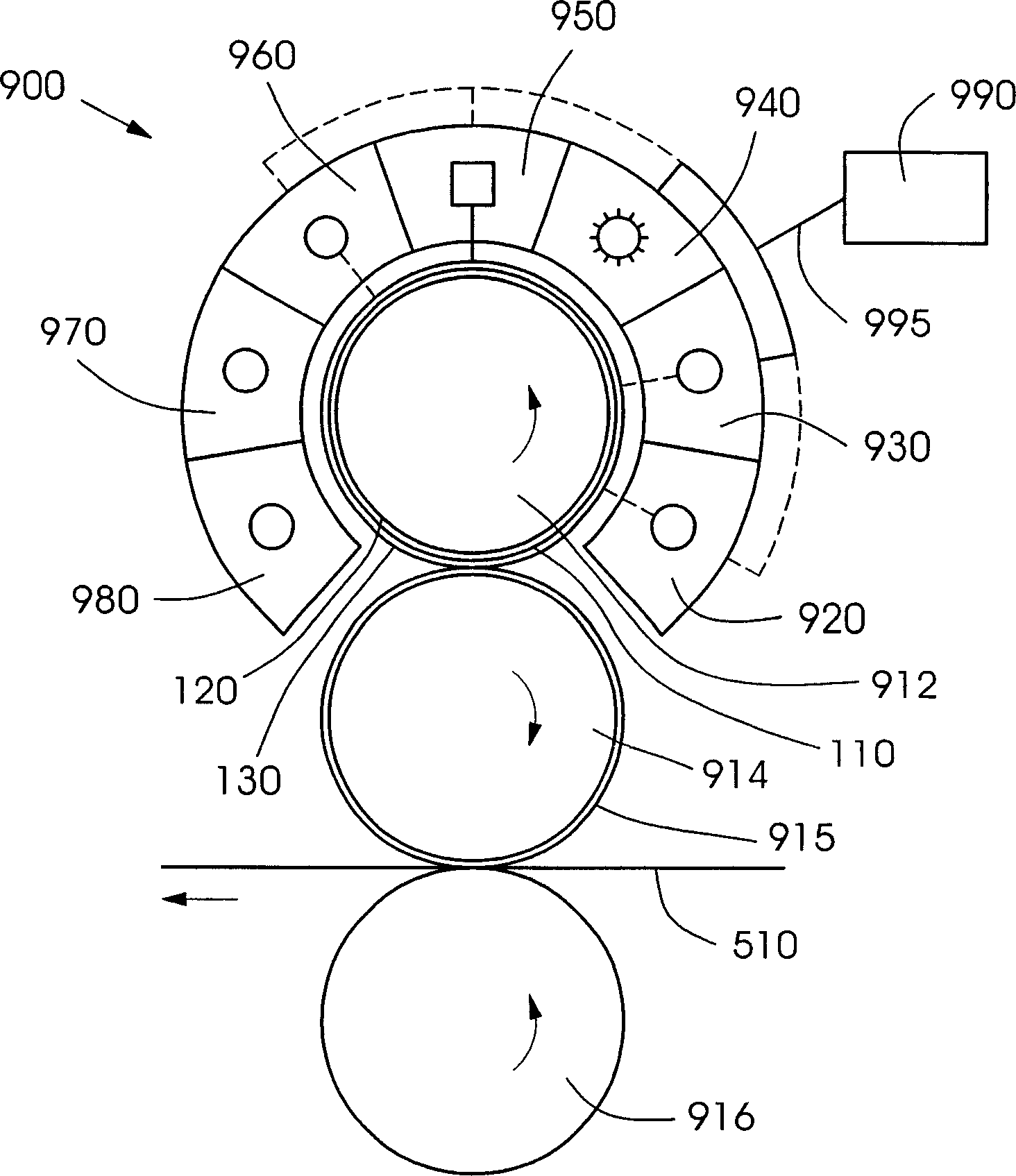

Method and apparatus for treating a re-imageble printing plate

InactiveCN1830682ASeparate steps to avoid cleanupSatisfied with cleaning resultsPlate printingFoil printingEngineeringPrinting ink

The present invention relates to method of treating printing plate after printing for re-imaging, and the printing plate has one carrier for applying amphoteric molecules. Before reuse in printing, amphoteric molecules are applied to the printing plate to clean off printing ink basically for re-imaging.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Graphene oxide/molecularly imprinted composite material, and preparation method and application thereof

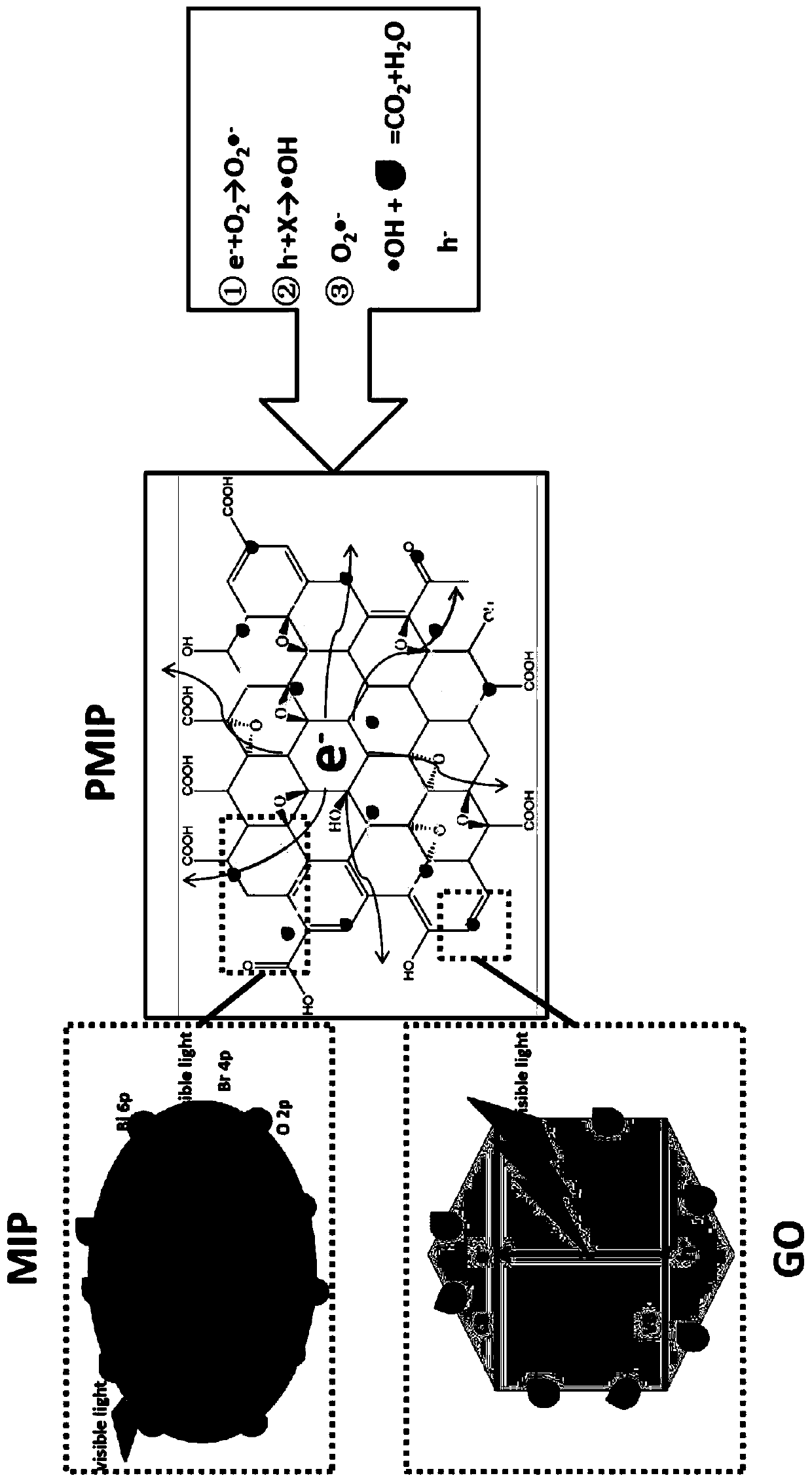

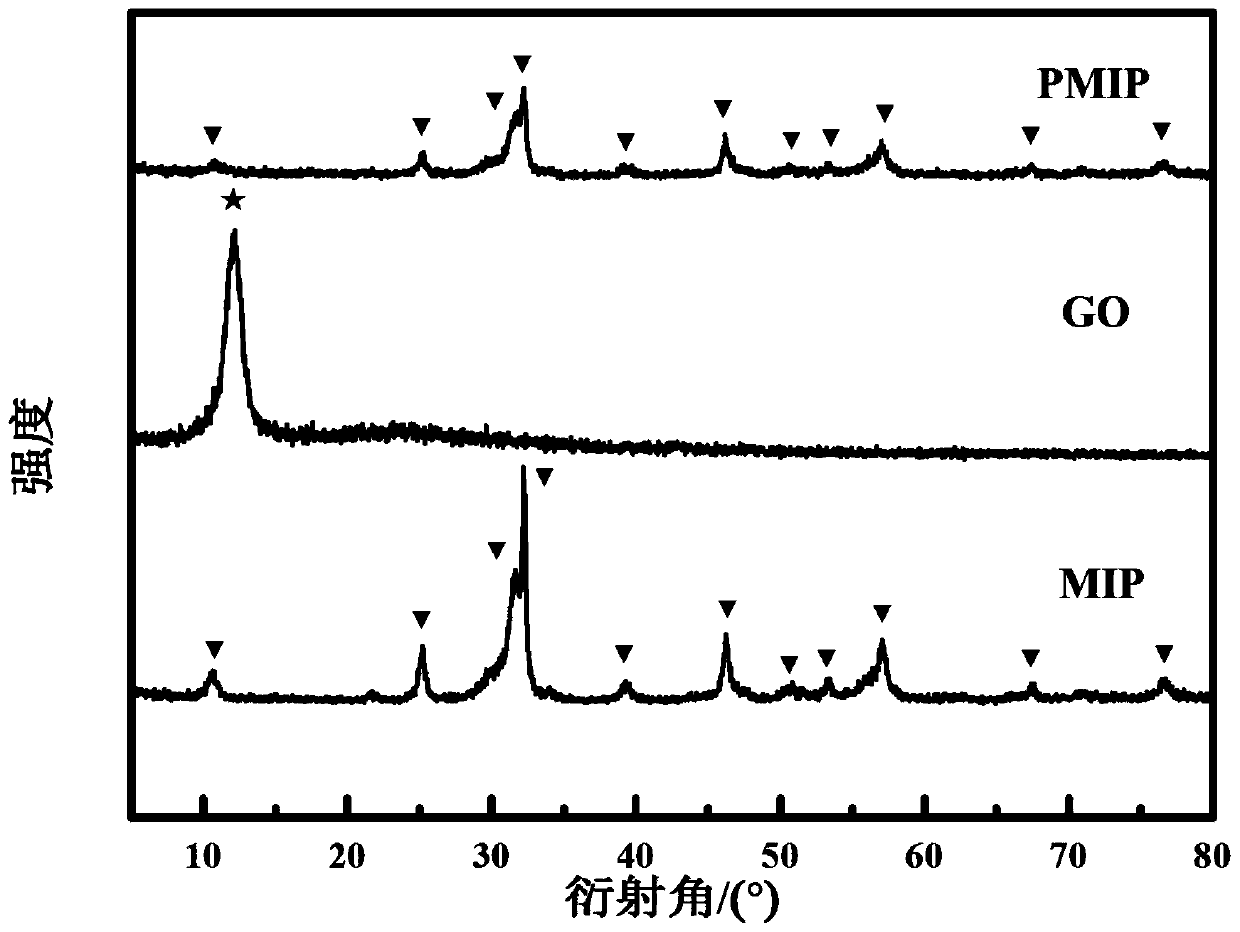

ActiveCN111013654AImprove photocatalytic performanceImprove adsorption capacityWater/sewage treatment by irradiationOther chemical processesFunctional monomerCross linker

The invention provides a graphene oxide / molecularly imprinted composite material, and a preparation method and an application thereof, and belongs to the technical field of organic pollutant degradation. The preparation method of the graphene oxide / molecularly imprinted composite material comprises the following steps: mixing template molecules, a functional monomer and a pore-foaming agent, and carrying out a pre-polymerization reaction to obtain a prepolymer; mixing the prepolymer, a first cross-linking agent, an initiator and BiOBr, and carrying out a polymerization reaction under a protective atmosphere condition to obtain a first polymer; eluting the first polymer to obtain a molecularly imprinted polymer; and mixing the molecularly imprinted polymer, graphene oxide, a solvent and a second cross-linking agent, and carrying out a cross-linking reaction to obtain the graphene oxide / molecularly imprinted composite material. The prepared graphene oxide / molecularly imprinted compositematerial has excellent selective adsorption performance and photocatalytic performance, and is long in cycle life.

Owner:TAIYUAN UNIV OF TECH

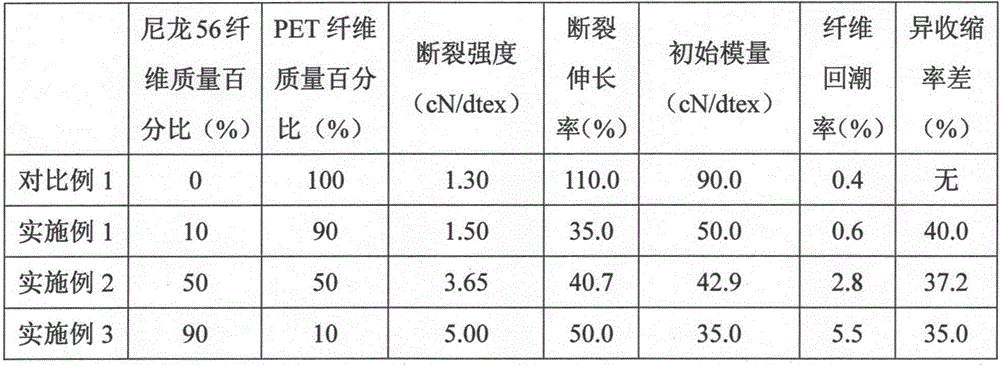

FDY/POY different shrinkage combined filament yarn of biomass nylon 56 fiber/PET fiber and preparing method thereof

InactiveCN105803571AGood hydrophilicGood flexibilityConjugated synthetic polymer artificial filamentsMaterials scienceBiomass

The invention discloses FDY / POY different shrinkage combined filament yarn of biomass nylon 56 fiber / PET fiber.The combined filament yarn is characterized by being prepared by spinning biomass nylon 56 fiber slices and PET slices; the biomass nylon 56 fiber is FDY fiber and the PET fiber is POY fiber, or the biomass nylon 56 fiber is POY fiber, and the PET fiber is FDY fiber.The difference between the boiling water shrinkage of the biomass nylon 56 fiber and that of the PET fiber is equal to or larger than 30%.According to the obtained FDY / POY different shrinkage combined filament yarn of the biomass nylon 56 fiber / PET fiber, the surfaces of tows curl slightly and naturally, hydrophily and softening property of the tows are obviously improved, and the FDY / POY different shrinkage combined filament yarn can be used for developing imitated cotton and imitated silk fabric.

Owner:DONGHUA UNIV +2

A kind of electrothermal film and its preparation method and application

ActiveCN107592688BExtended service lifeAvoid the problem of electrothermal performance attenuationOhmic-resistance heating detailsHeating element materialsFiberThermal insulation

The invention discloses an electric heating film and a preparation method and an application thereof. The electric heating film comprises a waterproof layer, an insulating layer, an electric heating layer, an electrode, an insulating layer, a thermal insulation layer and a waterproof layer and the like; the electric heating layer comprises fiber base fabric, a high-conductivity nanometer carbon material and a functional auxiliary; and the high-conductivity nanometer carbon material is adsorbed on the surface or in the gap of the fiber base fabric. The preparation method comprises the steps oftaking the fiber base fabric as the bearing substrate of the high-conductivity nanometer carbon material, performing wetting to form a hydrophilic treatment liquid firstly, next, performing baking andcuring, then coating with a wetted nanometer carbon aqueous dispersion liquid, and next, performing baking and curing to obtain the electric heating layer; and next, gluing with the insulating layer,the thermal insulation layer, the waterproof layer and the electrode through hot melt adhesive to form the electric heating film. The electric heating film is free of binder resin, so that the problem of electric heating performance degradation caused by resin aging can be obviously avoided; and the electric heating film has the integrated performance of electric heating, waterproof property, thermal insulation, reflection and the like, and can be widely applied to the industries of home heating, floor heating, thermal insulation, industrial heating and the like.

Owner:江西江铜碳纳米材料有限公司

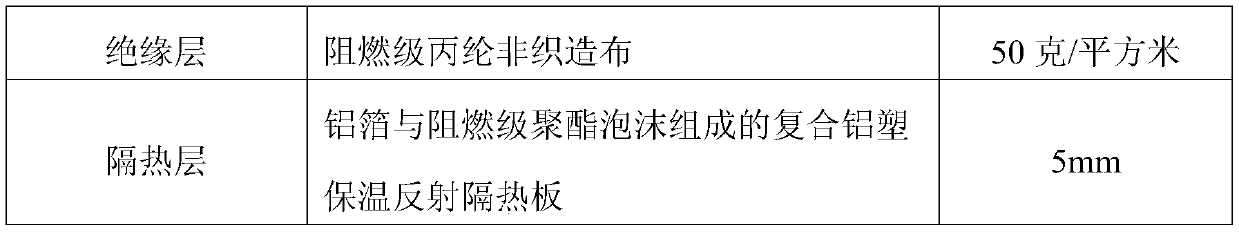

Environment-friendly odorless hydrophilic organic silicon softening agent for wool tops and preparation method of environment-friendly odorless hydrophilic organic silicon softening agent

The invention relates to the technical field of organic silicon softeners, in particular to an environment-friendly odorless hydrophilic organic silicon softener for wool tops and a preparation method thereof.The environment-friendly odorless hydrophilic organic silicon softener is prepared from, by mass, 100-200 kg of hydrogen-terminated silicone oil, 200-400 kg of allyl epoxy polyether, 0.1-1 kg of a catalyst, 60-90 kg of an amino silane coupling agent, 350-450 kg of an environment-friendly solvent, 5-20 kg of glacial acetic acid and the balance water. Due to the self-dispersion characteristic of amino polyether polysiloxane, the silicone oil can be self-emulsified in water, but due to intermolecular winding and the super-strong water absorption and thickening effect of polyether, if no solvent is involved, the emulsification can become very difficult. The silicone oil needs to be dispersed and diluted by a proper environment-friendly, odorless and non-toxic solvent to improve emulsification, so that a microemulsion which is suitable for use and has proper viscosity is prepared.

Owner:ZHEJIANG HAPPY CHEM

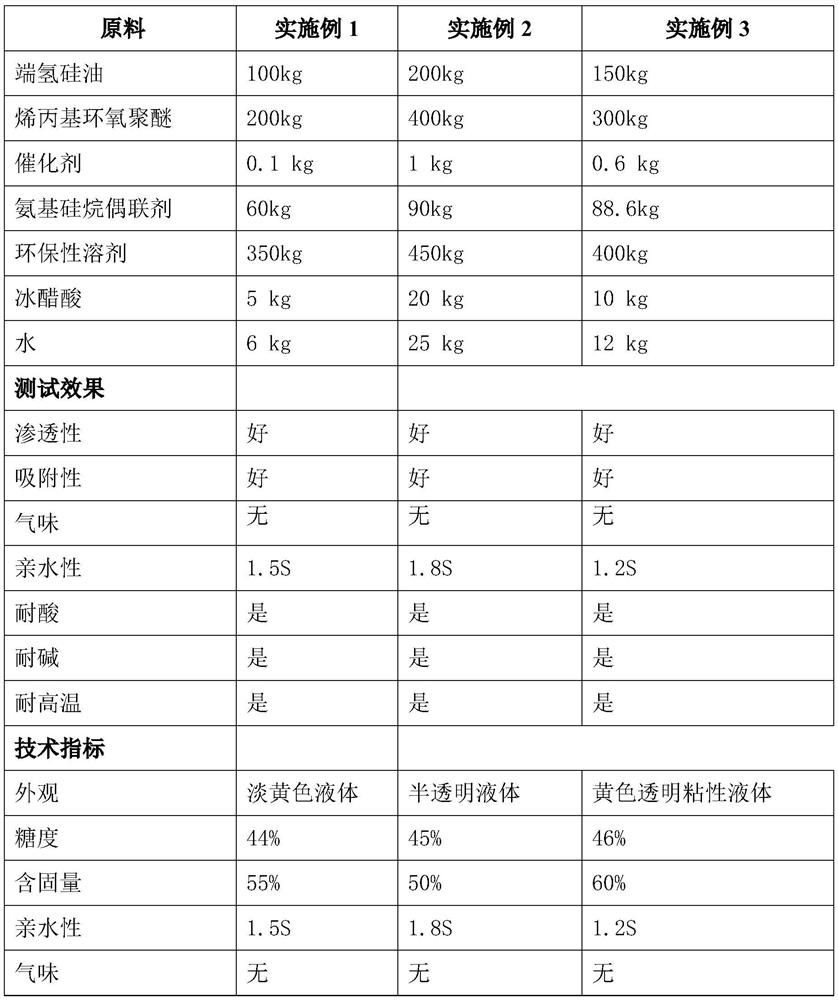

Preparation method of lacrimal duct plug with medicine slow release function

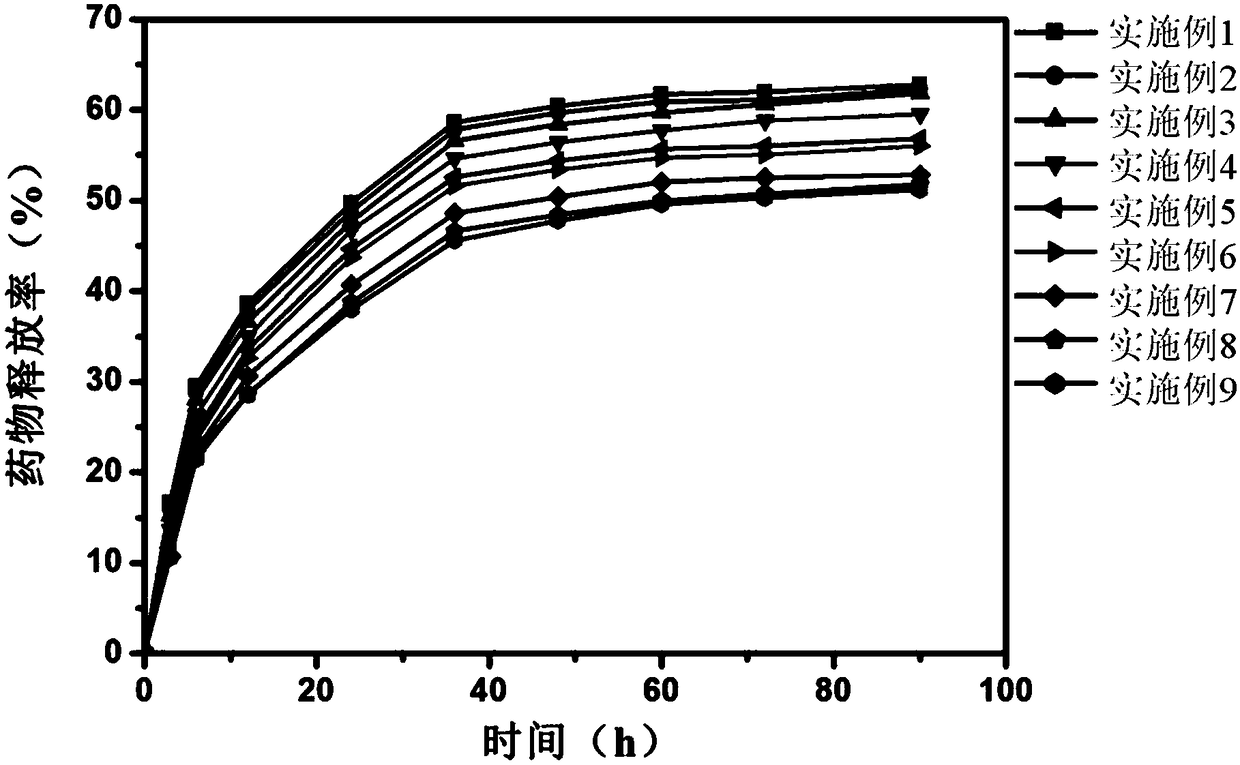

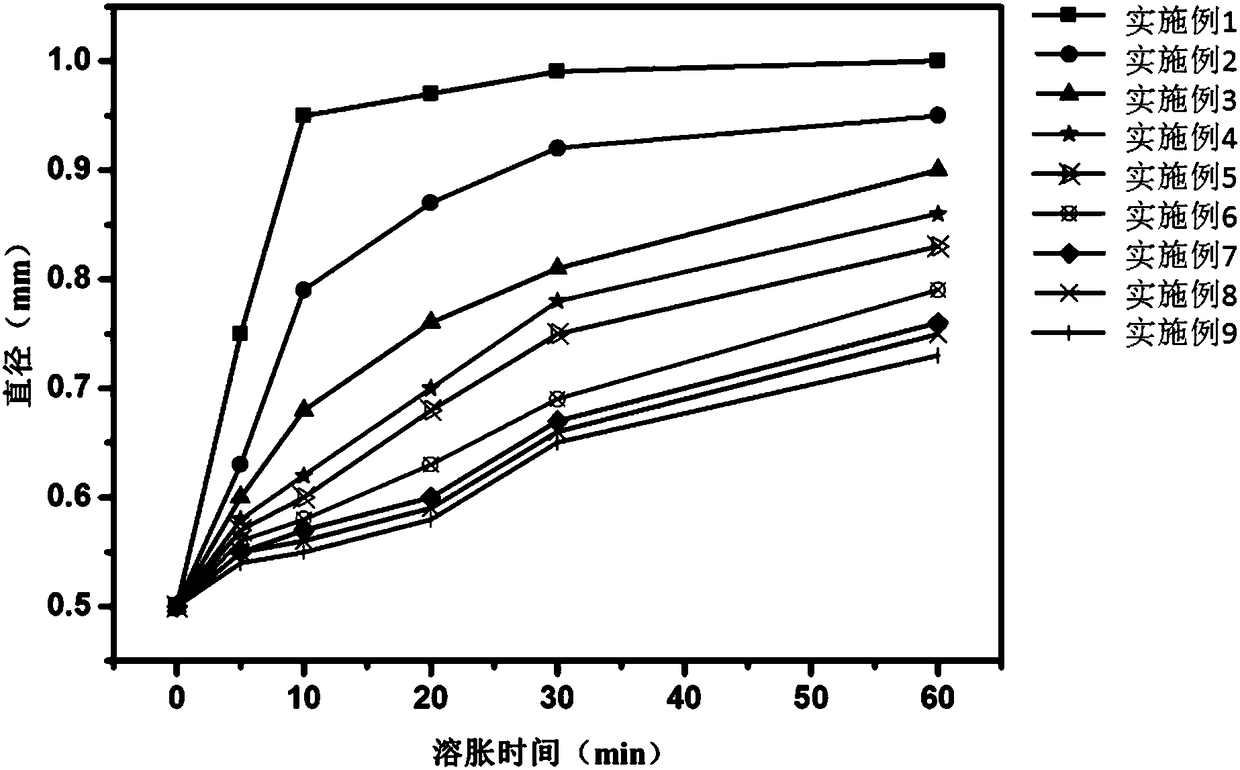

InactiveCN108395507AControllable and adjustable release rateExtended release timeSurgical adhesives(Hydroxyethyl)methacrylateMedicine

The invention discloses a preparation method of a lacrimal duct plug with a medicine slow release function. The method comprises the following steps of (1) uniformly mixing preparation raw materials of the lacrimal duct plug; injecting the materials into a mold; (2) performing reaction for 18 to 26h in the mold at 25 to 88 DEG C; performing curing shaping to obtain primarily shaped water gel; (3)performing UV irradiation on the primarily shaped water gel obtained in the step (2) for 5 to 30 min; performing further curing and shaping to obtain shaped water gel; (4) taking out the shaped watergel obtained in the step (3) from the mold; performing soaking and washing for 2 to 4 days by clean water; then, taking out the water gel; performing drying; obtaining the lacrimal duct plug with themedicine slow release function. The lacrimal duct plug uses hydroxyethyl methacrylate as a substrate; the medicine can be loaded; after the implementation by operation, the water absorption expansioncan be realized; the self fixing effect is achieved; the operative operation is facilitated; the medicine release speed can be regulated in a controllable way; the long-time implementation can be realized; the repulsion and the inflammation can be reduced; the excellent biocompatibility is realized.

Owner:广州锐澄医疗技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com