Surface modification method for raising activity of electrode material of vanadium cell

An electrode material and surface modification technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced battery life, high-temperature sintering with complicated steps of precious metal modification, and decreased stability of electrode materials, etc., to improve service life and price Effect of low cost and improved reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1

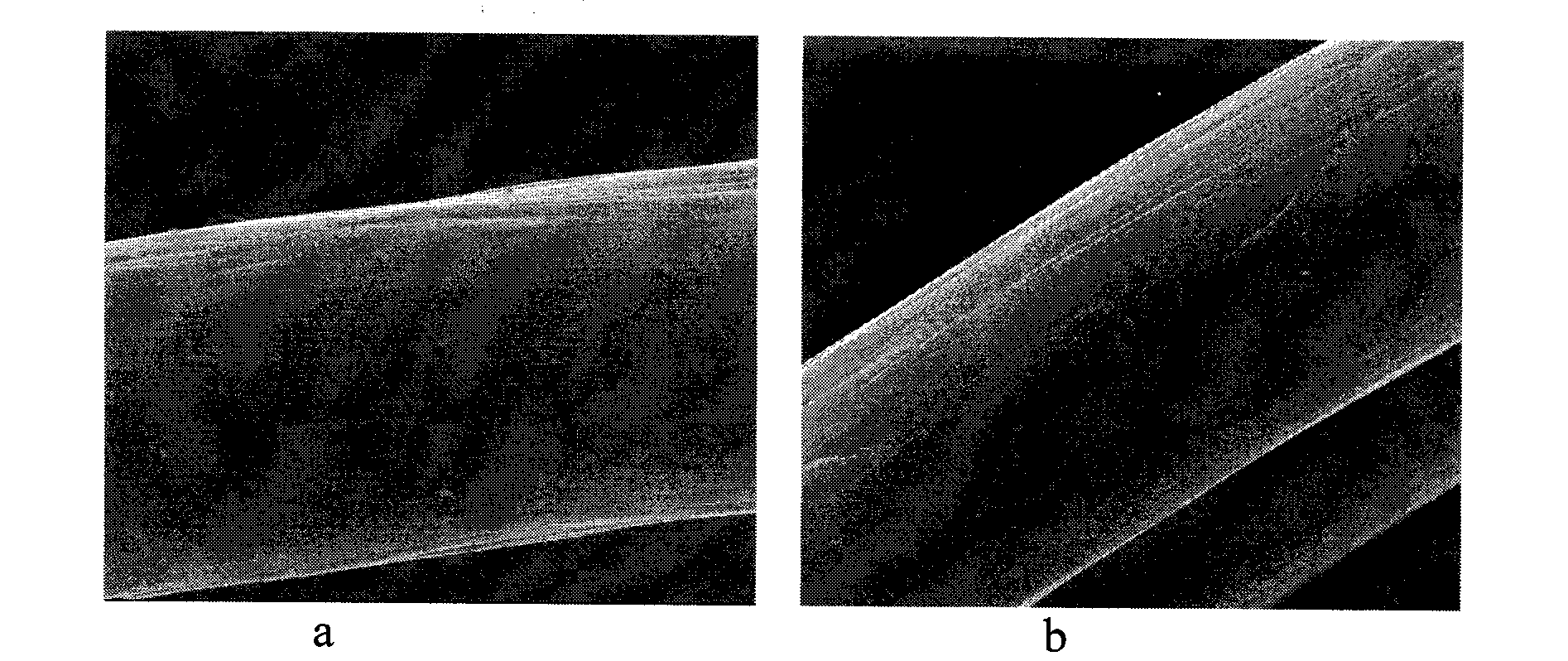

[0034] 1) Put the polypropylene carbon felt material with a thickness of 4mm in the superponement of the ultrasonic water in the ion water for 20min, put it in the oven at 75 ° C for 3 hours, and store it in the dryer for later use.

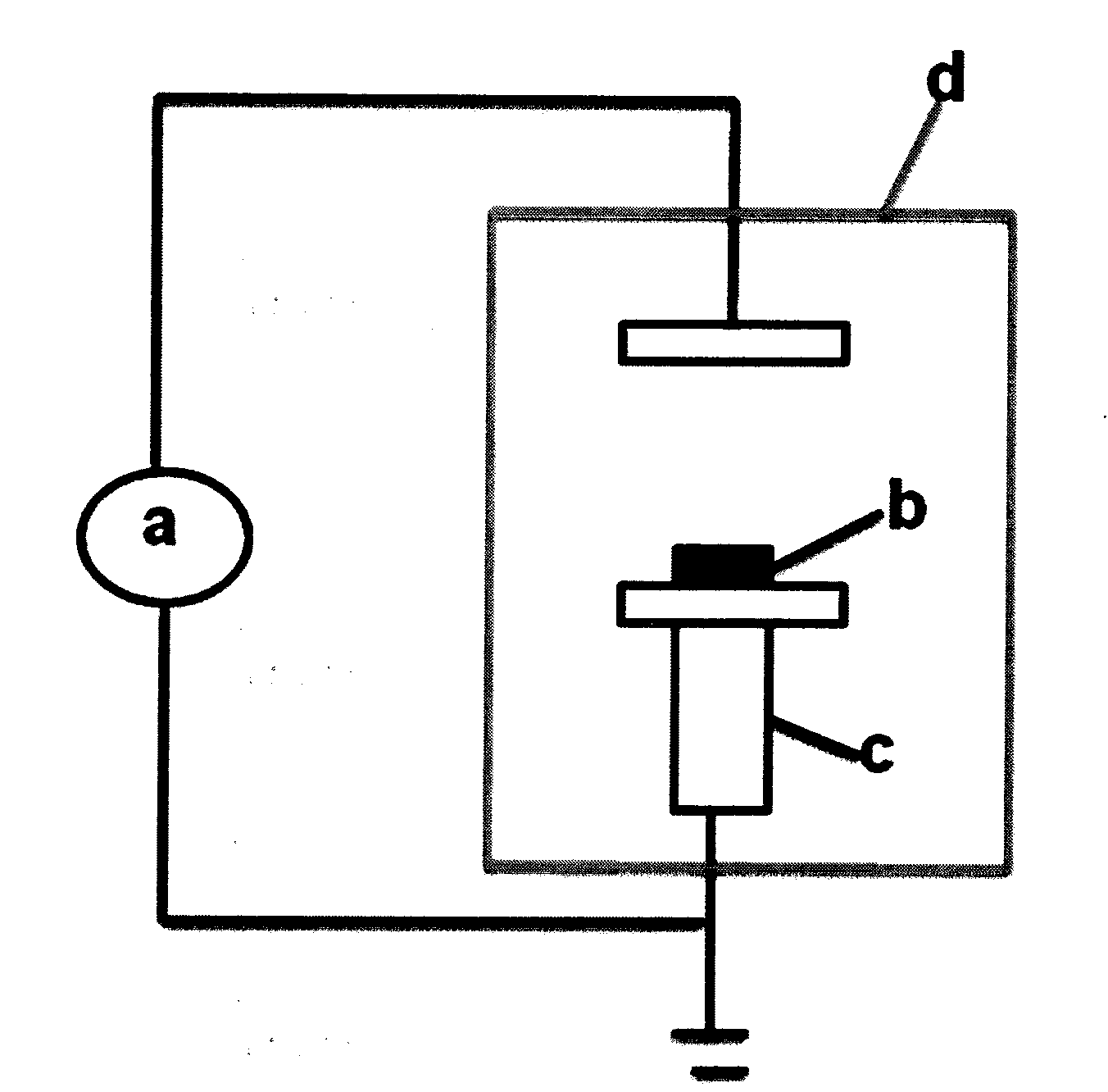

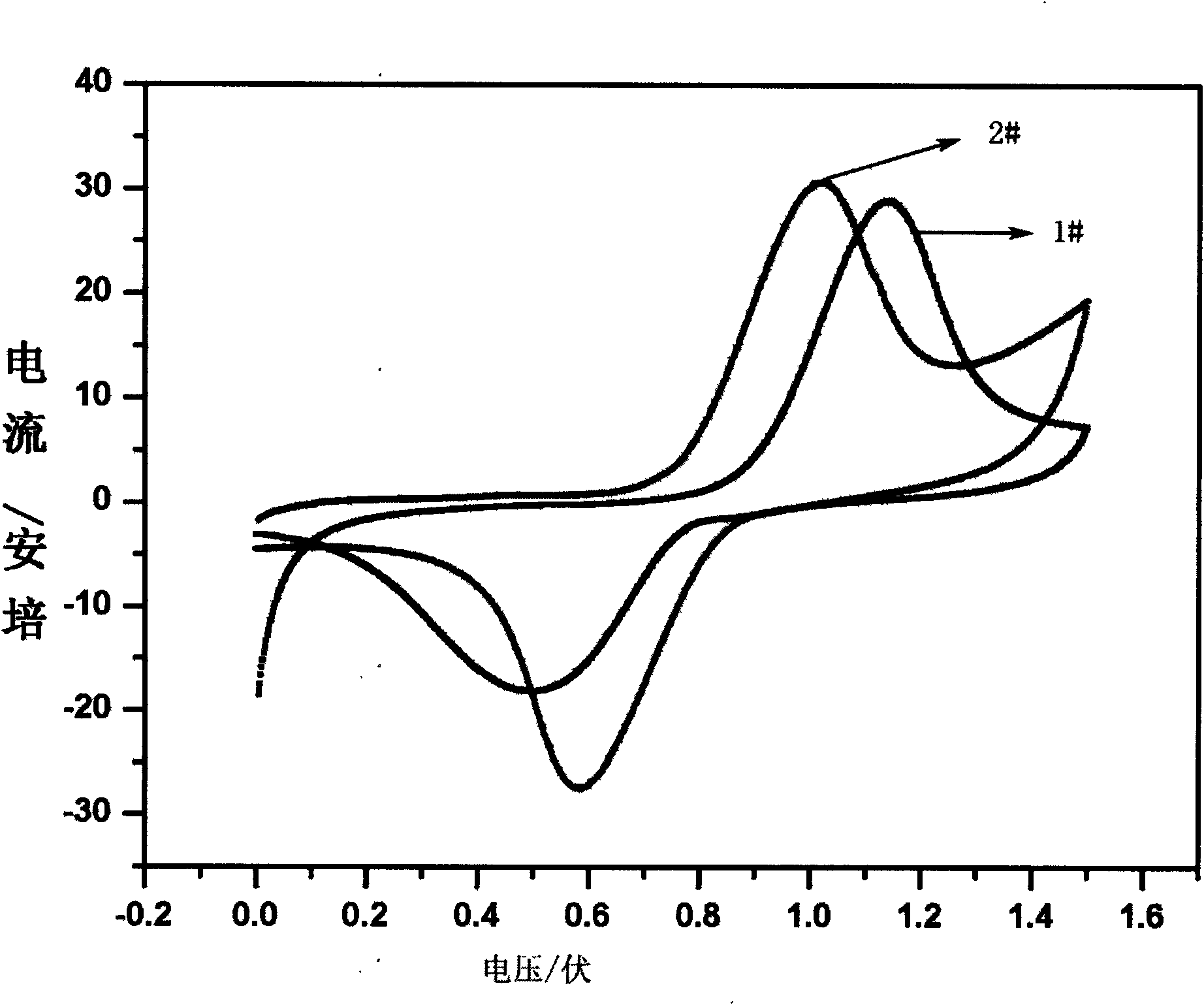

[0035] 2) Put the electrode material in the processing step 1) into the surface modified device of the ionic plasma plasma.The structure of the surface modification device of RF plasma is like figure 2 It is shown in the reaction room D. There is a sample table in the reaction room, and the ground end of RF generator A is connected to the sample table under the sample table. The other end of the RF generator A is connected to the electrode above the sample table in the reaction chamber D.When modifying the electrode material, put the electrode material as a sample B on the sample table.After the gas supply and vacuum system, the reaction chamber is vacuum, and then the reaction gas oxygen is used to maintain the pressure of the gas...

Embodiment 2

[0037] Example 2

[0038] The difference from Example 1 is:

[0039] 1) Put the graphite of a polypropylene cymbal with a thickness of 4mm and put it in the ultrasonic water in the ion water for 20min, put it in the oven at 75 ° C for 3 hours, and store it in the dryer for later use.

[0040] 2) Put the electrode material in the processing step 1) into the surface modified device of the ionic plasma plasma.After the gas supply and vacuum system, the reaction room was vacuum, and then the reaction gas nitrogen was passed in to maintain the pressure of the gas system of the reaction room by 150Pa. The processing time was 100s.The gas flow is 100ml / min.The instrument power is controlled at 200W.

[0041] 3) Wash the graphite -felt ultrasound of the step 2) for 5 minutes. Take it out and dry it at 100 ° C for 3 hours. You can use the electrode material of the battery to assemble the battery.

Embodiment 3

[0042] Example 3

[0043] The difference from Example 1 is:

[0044] 1) Put the graphite of a polypropylene cymbal with a thickness of 4mm and put it in the ultrasonic water in the ion water for 20min, put it in the oven at 75 ° C for 3 hours, and store it in the dryer for later use.

[0045] 2) Put the electrode material in the processing step 1) into the surface modified device of the ionic plasma plasma, and then draw the reaction room through the gas supply and vacuum system, and then pass the reaction gas ammonia gas to maintain the reaction room gas system systemThe pressure is 100Pa, and the processing time is from 300s.The gas flow is 100ml / min.The instrument power is controlled at 200W.

[0046] 3) Wash the graphite felt material in step 2) for 5 minutes. Take it out and dry at 100 ° C in the oven for 3 hours. You can use the electrode material for the battery to assemble the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com