Environment-friendly odorless hydrophilic organic silicon softening agent for wool tops and preparation method of environment-friendly odorless hydrophilic organic silicon softening agent

A technology of silicone softener and wool top, applied in the direction of improved hand fiber, textile and papermaking, fiber treatment, etc., can solve the problem of non-washable, poor acid and alkali resistance of silicone softener, silicone softener Problems such as smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

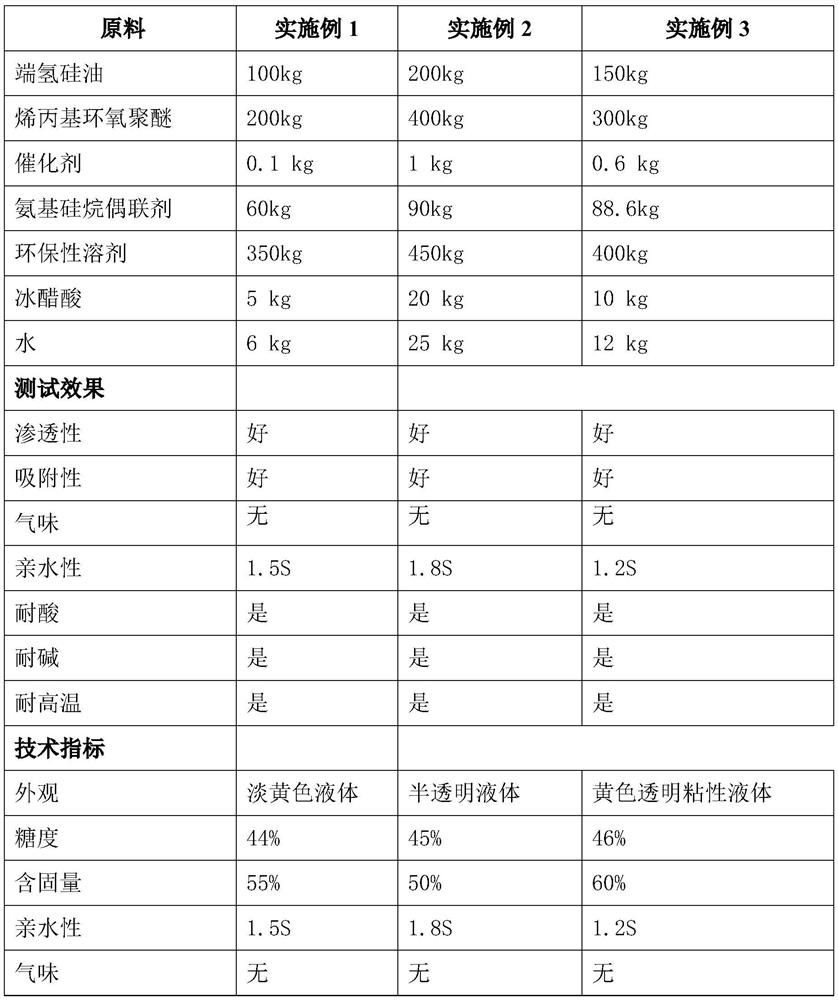

Embodiment 1

[0035] Environmentally friendly and odorless hydrophilic silicone softener for wool tops, composed of the following quality components:

[0036] 100kg of hydrogen-terminated silicone oil, 200kg of allyl epoxy polyether, 0.1kg of catalyst, 60kg of aminosilane coupling agent, 350kg of environmentally friendly solvent, 5kg of glacial acetic acid, and the balance is water.

[0037] The environment-friendly and tasteless hydrophilic silicone softener for wool tops is prepared by the following method: step (1) preparation of component I:

[0038] Take 100kg of terminal hydrogen-containing silicone oil and 200kg of allyl epoxy polyether and put them into a 500kg reaction kettle, open the inert gas bottle, adjust the appropriate flow rate, then raise the temperature of the material to 35°C, and add 1kg of catalyst. The temperature was then raised to 110°C and kept at this temperature for 5 hours to obtain Component I.

[0039] Step (2) prepares component II:

[0040] After the heat ...

Embodiment 2

[0050] Environmentally friendly and odorless hydrophilic silicone softener for wool tops, composed of the following quality components:

[0051]200kg of hydrogen-terminated silicone oil, 400kg of allyl epoxy polyether, 1kg of catalyst, 90kg of aminosilane coupling agent, 450kg of environmentally friendly solvent, 20kg of glacial acetic acid, and the balance is water.

[0052] The environment-friendly and tasteless hydrophilic silicone softener for wool tops is prepared by the following method: step (1) preparation of component I:

[0053] Take 200kg of terminal hydrogen-containing silicone oil and 400kg of allyl epoxy polyether and put them into a 1000kg reaction kettle, open the inert gas bottle, adjust the appropriate flow rate, then raise the temperature of the material to 45°C, and add 10kg of catalyst. The temperature was then raised to 130°C and maintained at this temperature for 4 hours to obtain Component I.

[0054] Step (2) prepares component II:

[0055] After the...

Embodiment 3

[0065] Environmentally friendly and odorless hydrophilic silicone softener for wool tops, composed of the following quality components:

[0066] 150kg of hydrogen-terminated silicone oil, 300kg of allyl epoxy polyether, 0.6kg of catalyst, 88.6kg of aminosilane coupling agent, 400kg of environmentally friendly solvent, 10kg of glacial acetic acid, and the balance is water.

[0067] The environment-friendly and tasteless hydrophilic silicone softener for wool tops is prepared by the following method: step (1) preparation of component I:

[0068] Take 150kg of terminal hydrogen-containing silicone oil and 300kg of allyl epoxy polyether and put them into a 1000kg reaction kettle, open the inert gas bottle, adjust the appropriate flow rate, then raise the temperature of the material to 38°C, and add 6kg of catalyst. The temperature was then raised to 120°C and maintained at this temperature for 4.5 hours to obtain Component I.

[0069] Step (2) prepares component II:

[0070] Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com