Hydrophilic sponge material and preparation method thereof

A hydrophilic sponge and hydrophilic technology, which is applied in the field of hydrophilic sponge materials and its preparation, can solve the problems such as the decline of the physical properties of the sponge, and achieve the effects of excellent mechanical properties, improved hydrophilic properties, and good hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment hydrophilic sponge is made from the raw material of following parts by weight:

[0040] 100 parts of PPG, 25 parts of POP, 25 parts of hydrophilic polyols, 6.2 parts of water, 0.3 parts of bis(2-dimethylaminoethyl) ether amine catalyst, 0.4 parts of stannous octoate catalyst, 2 parts of hydrophilic silicone oil (9205) , Hydrophilic additive (HQ990) 12 parts, TDI 85 parts.

[0041] Mix and foam the above raw materials evenly at room temperature, the stirring speed is 3000rpm, the pressure is 40bar, and the foaming speed is 3-5m / min to form a strip or block foam sponge. After aging at room temperature for 24-30h, it becomes a hydrophilic sponge material .

[0042] The prepared hydrophilic sponge material was tested, and the test results are shown in Table 1.

Embodiment 2

[0044] 80 parts of PPG, 5 parts of POP, 15 parts of hydrophilic polyol, 2.6 parts of water, 0.28 parts of bis(2-dimethylaminoethyl) ether amine catalyst, 0.28 parts of stannous octoate catalyst, 1.2 parts of hydrophilic silicone oil (9205) , 8 parts of hydrophilic additive (HQ990), 85 parts of TDI.

[0045] Mix and foam the above raw materials evenly at room temperature, the stirring speed is 4000rpm, the pressure is 60bar, and the foaming speed is 3-5m / min to form a strip or block foam sponge. After aging at room temperature for 24-30h, it becomes a hydrophilic sponge material .

[0046] The prepared hydrophilic sponge material was tested, and the test results are shown in Table 1.

Embodiment 3

[0048] 0 part of PPG, 25 parts of POP, 75 parts of hydrophilic polyol, 2.5 parts of water, 0.55 part of bis(2-dimethylaminoethyl)ether amine catalyst, 55 parts of MDI.

[0049] Mix and foam the above raw materials evenly at room temperature, the stirring speed is 4000rpm, the pressure is 60bar, and the foaming speed is 3-5m / min to form a strip or block foam sponge. After aging at room temperature for 24-30h, it becomes a hydrophilic sponge material .

[0050] The prepared hydrophilic sponge material was tested, and the test results are shown in Table 1.

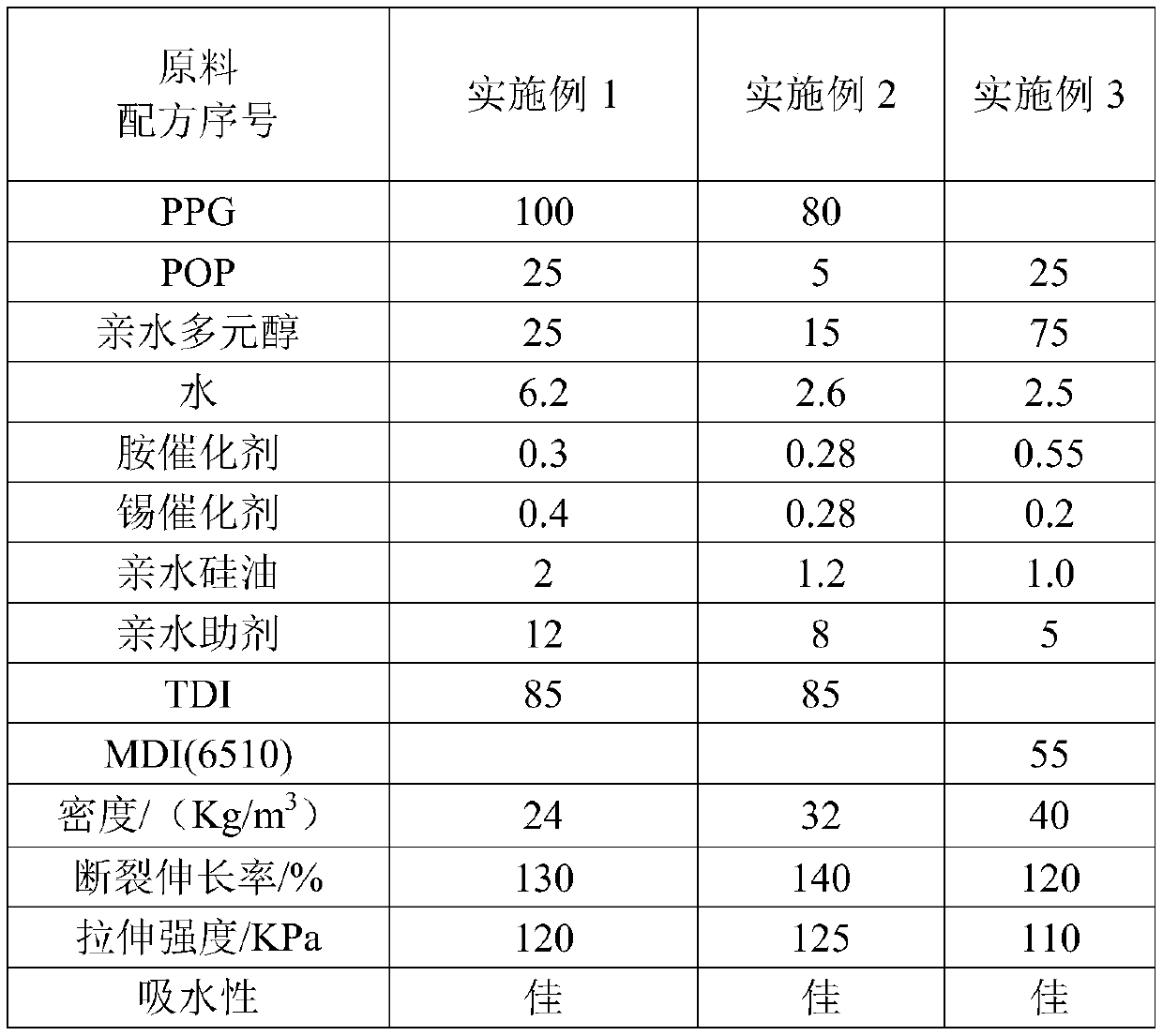

[0051] The formulations and physical properties of Examples 1-3 are shown in Table 1 below.

[0052] Table 1:

[0053]

[0054] The polyurethane sponge material (5g) that embodiment 1-3 obtains is put into water, 5~10s can sink to the bottom of the water, and through testing, the water absorption of the polyurethane sponge material prepared in embodiment 1 is 50g / g; Embodiment 2 The water absorption of the polyurethane sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com