Anti-glare and anti-fogging glass as well as surface treatment fluid thereof and preparation method thereof

A surface treatment liquid, anti-fogging technology, applied in the field of materials, can solve the problems of easy wear and tear, environmental sanitation and human health hazards, short service life, etc., to solve the problem of condensation, highlight the advantages of environmental protection, avoid environmental sanitation and Effects of harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

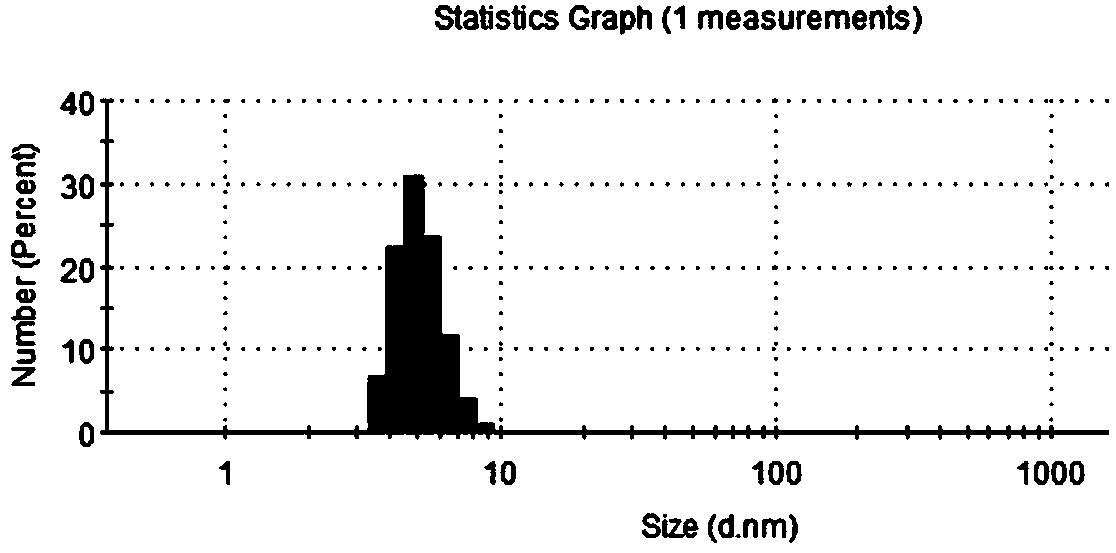

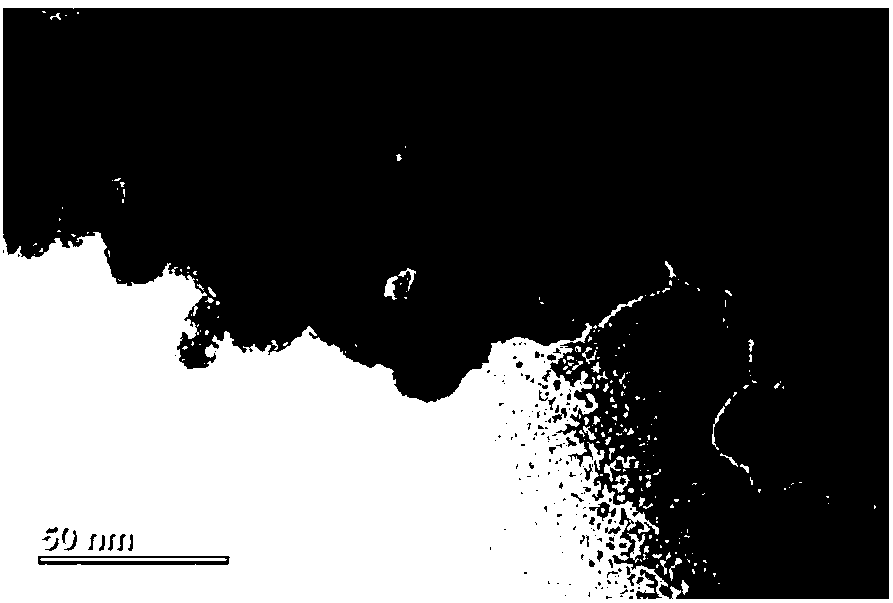

Image

Examples

Embodiment 1

[0054] A surface treatment solution for anti-glare and anti-fogging glass, which comprises tetraethyl orthosilicate, amino acid, water and alcohol, and the mass ratio of said tetraethyl orthosilicate, amino acid, water and alcohol is 1: 0.02:16:2. Wherein, the alcohol is at least one of methanol, ethanol, isopropanol, and butanol; the amino acid is at least one of basic amino acids such as arginine, lysine, and histidine. Methanol and arginine are used in this example.

[0055] The surface treatment solution of the anti-glare and anti-fogging glass is prepared by the following steps:

[0056] 1. Add an appropriate amount of a mixture of deionized water and ethanol to the jacketed double-layer reactor, and control the temperature of the circulating water in the jacket at 60°C.

[0057] 2. When the temperature of the deionized water in the reactor reaches the set value, add an appropriate amount of arginine into the reactor and stir to dissolve it completely.

[0058] 3. Add ...

Embodiment 2

[0068] A surface treatment liquid for anti-glare and anti-fogging glass. On the basis of Example 1, the mass ratio of tetraethyl orthosilicate, amino acid, water and alcohol is 1:0.05:20:0.5. Wherein, the alcohol is at least one of methanol, ethanol, isopropanol, and butanol; the amino acid is at least one of basic amino acids such as arginine, lysine, and histidine. In this example, ethanol and lysine are used.

[0069] The surface treatment solution of the anti-glare and anti-fogging glass is prepared by the following steps:

[0070] 1. Add an appropriate amount of a mixture of deionized water and ethanol to the jacketed double-layer reactor, and control the temperature of the circulating water in the jacket at 80°C;

[0071] 2. When the temperature of the deionized water in the reactor reaches the set value, add an appropriate amount of arginine into the reactor and stir to dissolve it completely.

[0072] 3. Add an appropriate amount of ethyl orthosilicate to the reactio...

Embodiment 3

[0079] A surface treatment liquid for anti-glare and anti-fogging glass. On the basis of Example 1, the mass ratio of tetraethyl orthosilicate, amino acid, water and alcohol is 1:0.01:8:3. Wherein, the alcohol is at least one of methanol, ethanol, isopropanol, and butanol; the amino acid is at least one of basic amino acids such as arginine, lysine, and histidine. In this example, isopropanol and histidine were used.

[0080] The surface treatment solution of the anti-glare and anti-fogging glass is prepared by the following steps:

[0081] 1. Add an appropriate amount of a mixture of deionized water and ethanol to the jacketed double-layer reactor, and control the temperature of the circulating water in the jacket at 55°C;

[0082] 2. When the temperature of the deionized water in the reactor reaches the set value, add an appropriate amount of arginine into the reactor and stir to dissolve it completely.

[0083] 3. Add an appropriate amount of ethyl orthosilicate to the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com