Vapor chamber with gradient wick structure and preparation method thereof

A technology of liquid-absorbing core and soaking plate, which is applied in lighting and heating equipment, indirect heat exchangers, modification by using liquid cooling, etc., can solve the problem of liquid-absorbing core with large capillary driving force and high permeability It can further improve the performance of the vapor chamber, reduce the overall performance of the vapor chamber, etc., and achieve the effects of enhancing heat transfer performance and working stability, improving hydrophobic characteristics, and improving hydrophilic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

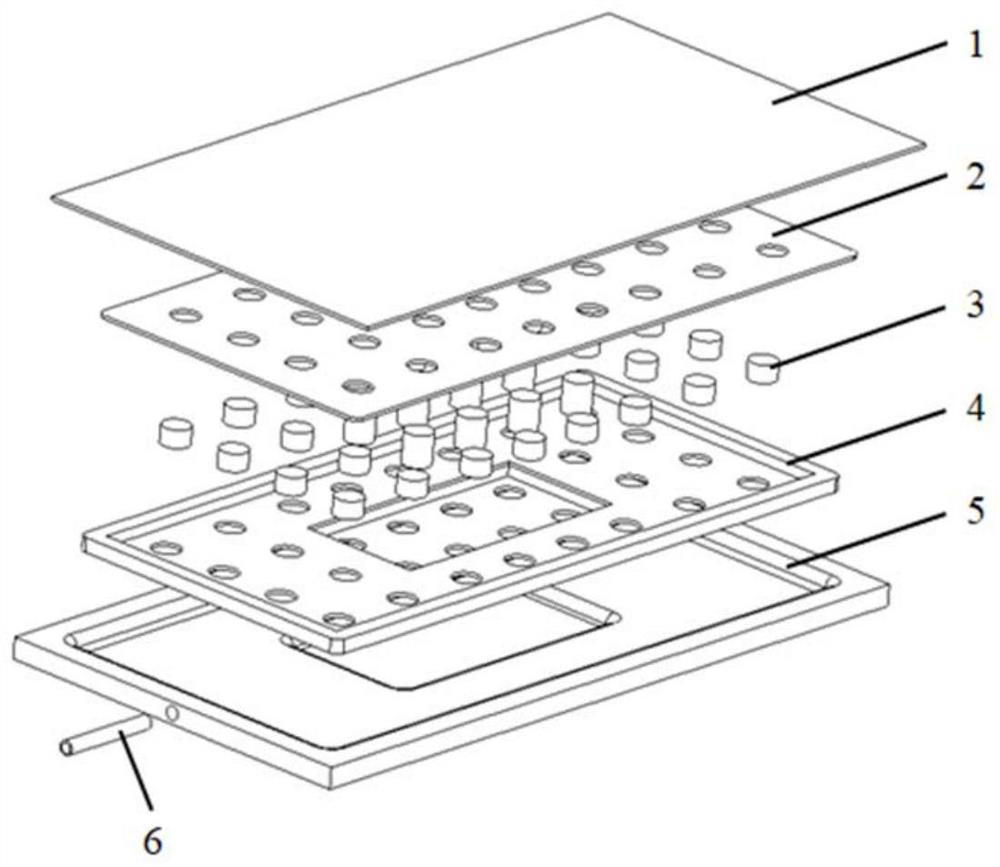

[0084] Such as figure 1 As shown, the vapor chamber of this embodiment includes: an upper shell plate 1 , a liquid-absorbing core 2 at the condensation end, a support column 3 , a liquid-absorbing core 4 at the evaporation end, a lower shell plate 5 and a liquid injection pipe 6 .

[0085] The thicknesses of the upper shell plate and the lower shell plate are 0.5 mm and 1.5 mm respectively.

[0086] The lower shell plate is stepped, and the protruding part is the area of the tooling surface where the heat source contacts.

[0087] The lower shell plate leaves a liquid injection port for placing a liquid injection pipe.

[0088] The upper shell plate and the lower shell plate are respectively sintered with a condensing end liquid-absorbing core and an evaporating end liquid-absorbing core.

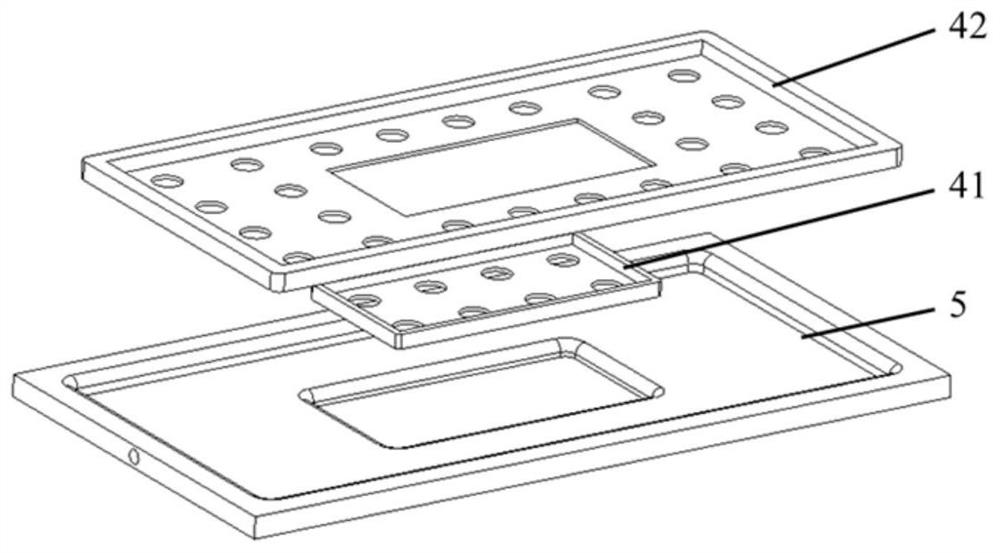

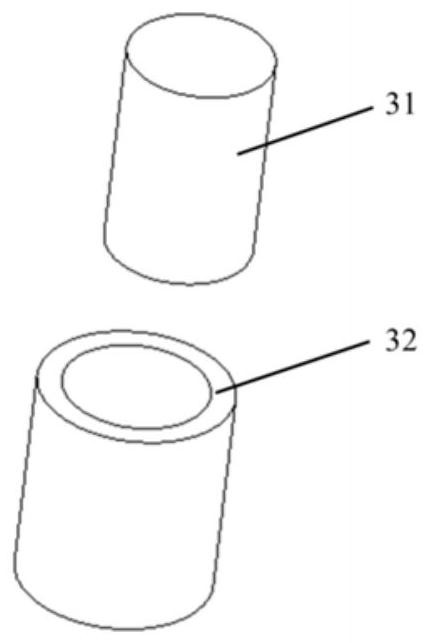

[0089] The evaporating end liquid-absorbing core includes #1 evaporating-end liquid-absorbing core 41 on the working surface area and #2 evaporating end liquid-absorbing core 42 away fr...

Embodiment 2

[0101] Such as Figure 7 As shown, the vapor chamber of this embodiment is different from that of Embodiment 1: the structural shape of the lower shell of the vapor chamber in Embodiment 2 is flat. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com