Anti-electrostatic degradable film material and preparation method thereof

A degradable film and anti-static technology, which is applied in the field of polymer materials, can solve the problems of product damage, economic loss, and lack of anti-static performance, and achieve the effect of solving static damage, good degradation performance, and reducing static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

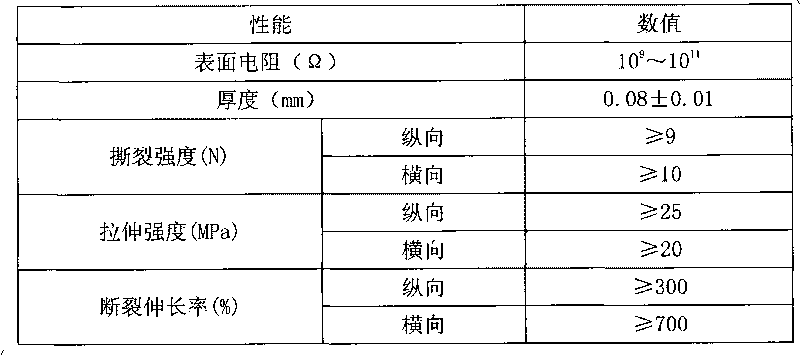

Image

Examples

Embodiment 1

[0027] Embodiment 1. An antistatic degradable film material is made of the following raw materials in parts by weight: 60 parts of LDPE, 18 parts of LLDPE, 10 parts of a compound blended with thermoplastic starch and aliphatic polyester, antistatic masterbatch 2 parts of granules, wherein the mixing weight ratio between thermoplastic starch and aliphatic polyester is 1:1.

[0028] Preparation:

[0029] (1), weigh LDPE, LLDPE, starch-based degradable plastic raw materials and antistatic masterbatch, and mix them uniformly to form a mixture;

[0030] (2) Put the mixture into the film blowing machine for plasticizing and extruding; the temperature of the feeding section of the blowing film machine is set at 130°C to 140°C, and the temperature of the plasticizing section is set at 160°C to 175°C. Die head temperature 160°C;

[0031] (3), the plasticized extruded material is blown and drawn to make a film, and then the air ring is cooled; wherein the blow-up ratio is 2.5, and the...

Embodiment 2

[0034] Embodiment 2. An antistatic degradable film material is made of the following raw materials in parts by weight: 27 parts of LDPE, 18 parts of LLDPE, 30 parts of a compound blended with thermoplastic starch and aliphatic polyester, antistatic masterbatch 5 parts of granules, wherein the mixing weight ratio between thermoplastic starch and aliphatic polyester is 1:1.5.

[0035] Preparation method: Preparation method:

[0036] (1), weigh LDPE, LLDPE, starch-based degradable plastic raw materials and antistatic masterbatch, and mix them uniformly to form a mixture;

[0037] (2) Put the mixture into the film blowing machine for plasticizing and extruding; the temperature of the feeding section of the blowing film machine is set at 130°C to 140°C, and the temperature of the plasticizing section is set at 160°C to 175°C. Die head temperature 160°C;

[0038] (3), the plasticized extruded material is blown and drawn to make a film, and then the air ring is cooled; wherein the ...

Embodiment 3

[0040] Embodiment 3. An antistatic degradable film material is made of the following raw materials in parts by weight: 30 parts of LDPE, 15 parts of LLDPE, 50 parts of thermoplastic starch and aliphatic polyester blended compound, antistatic masterbatch 5 parts of granules, wherein the mixing weight ratio between thermoplastic starch and aliphatic polyester is 1:1.

[0041] Preparation method: Preparation method:

[0042] (1), weigh LDPE, LLDPE, starch-based degradable plastic raw materials and antistatic masterbatch, and mix them uniformly to form a mixture;

[0043] (2) Put the mixture into the film blowing machine for plasticizing and extruding; the temperature of the feeding section of the blowing film machine is set at 130°C to 140°C, and the temperature of the plasticizing section is set at 160°C to 175°C. Die head temperature 160°C;

[0044] (3), the plasticized extruded material is blown and drawn to make a film, and then the air ring is cooled; wherein the blowing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com