Nickel hydrazine azide, its preparation method and uses as explosive ignitor

An azide and nickel salt technology, applied in the field of detonating medicinal compounds and their preparation, can solve the problems of long production cycle, large energy consumption, weak detonating power of nickel hydrazine nitrate, etc., and achieves low electrostatic accumulation, low mechanical sensitivity, The effect of low electrostatic spark sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

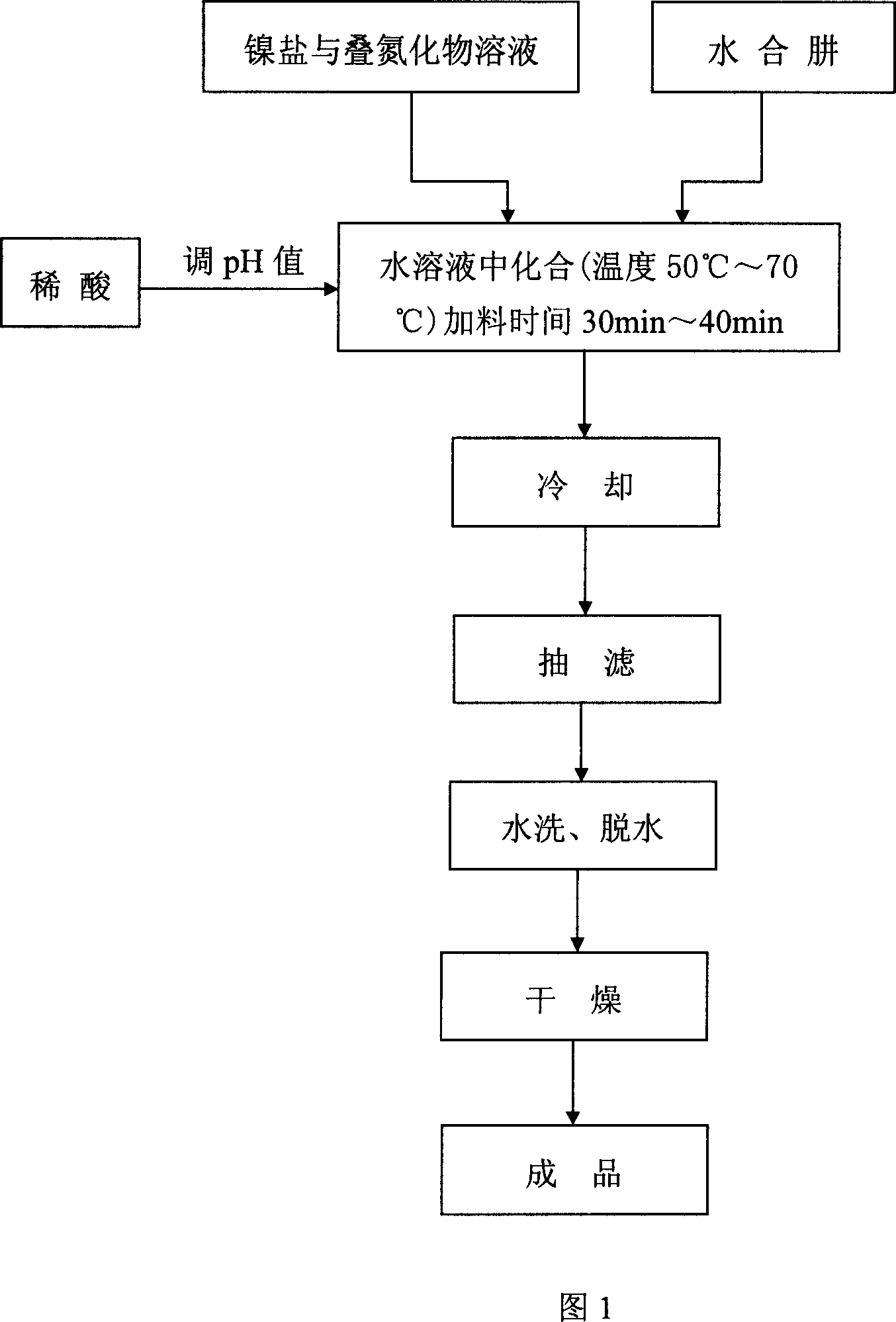

[0017] Embodiment 1: in conjunction with Fig. 1, raw material specification and requirement: hydrazine hydrate (N 2 h 4 ·H 2 O)AR, nickel nitrate (Ni(NO 3 ) 2 ) AR, sodium nitride (NaN 3 ) CP, nitric acid (HNO 3 ) CP, ethanol (C 2 h 5 OH)CP, main instruments and equipment: electric mixer; voltage regulating transformer; super constant temperature water bath; tall beaker (combiner) 400mL, Buchner funnel Ф65mm; filter bottle 1000mL, water bath oven, rotary vane vacuum pump.

[0018] The acidified 80mL deionized water was used as the reaction bottom liquid, placed in the compounder, and the raw material feeding ratio (mass ratio) was: Ni(NO 3 ) 2 ·6H 2 O:NaN 3 :N 2 h 4 ·H 2 O=2.19:1:0.80; feeding time: 30min~60min, compounding temperature: room temperature~70°C; heat the bottom solution in a constant temperature water bath to 60°C~70°C, start the stirrer at the same time, adjust the voltage to proper stirring state. Slowly add Ni(NO 3 ) 2 / NaN 3 The mixture and ...

Embodiment 2

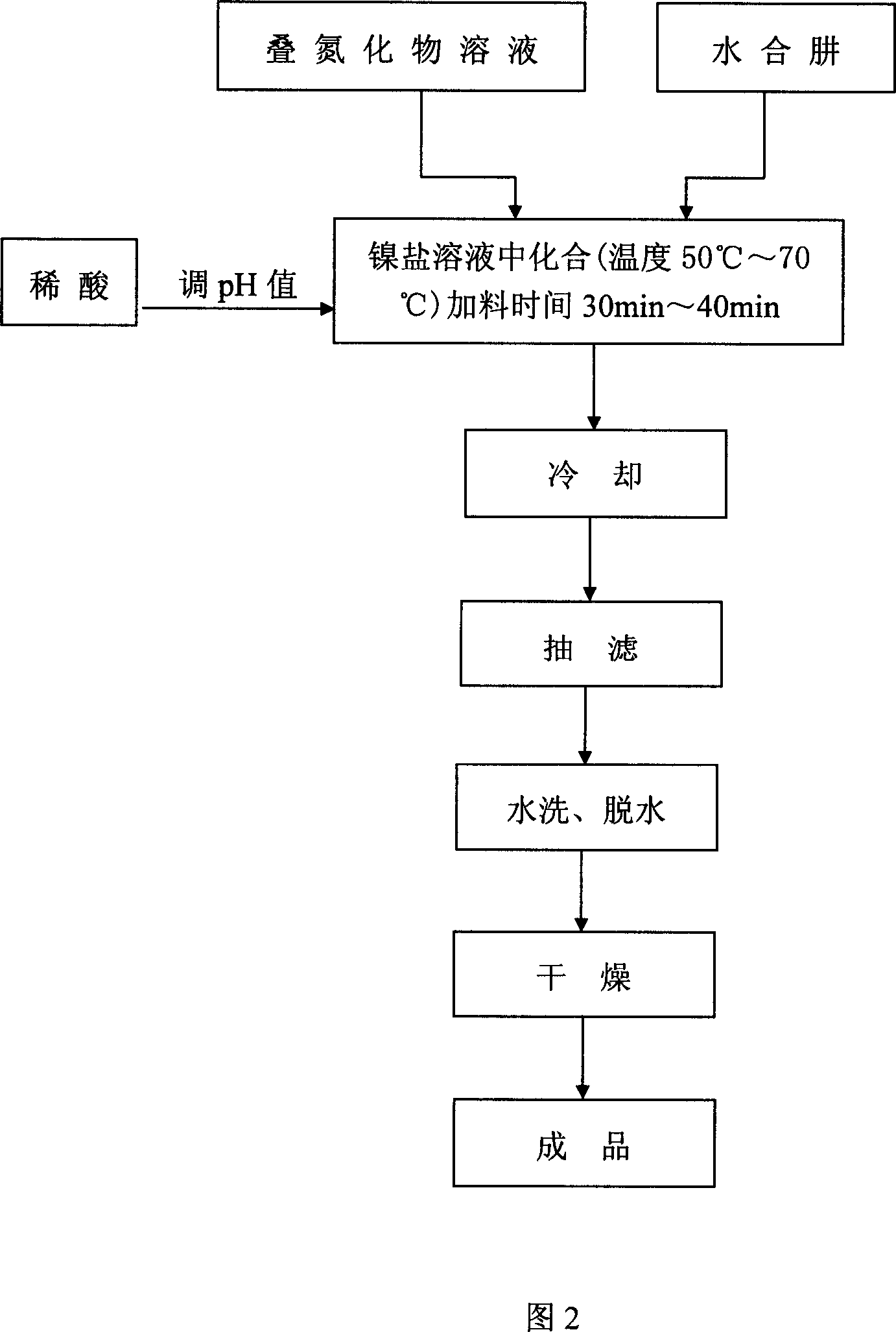

[0023] Embodiment 2: in conjunction with Fig. 2, the 80mL Ni(NO 3 ) 2 The solution is used as the reaction bottom liquid, placed in the compounder, then the stirrer is started, and the voltage is adjusted to a proper stirring state. Slowly add NaN dropwise at room temperature through the method of double-tube dropwise addition 3 solution and N 2 h 4 ·H 2 O solution, adjust the appropriate drop rate ratio. Continue to stir for 10 minutes after the addition is complete, and then discharge directly.

[0024] The operating method of suction filtration, washing, dehydration and drying is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com