Antistatic agent for polyester elasticizing oiling agent and manufacturing method thereof

A technology of antistatic agent and manufacturing method, which is applied in the field of antistatic agent and its manufacture, can solve problems such as poor see-through rate and antistatic property, poor frost resistance, and poor unwinding of texturizing oil, and achieve less static accumulation and antistatic Strong frost resistance and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The antistatic agent for polyester elastic finish described in this embodiment, by weight, comprises the following materials:

[0043] 40 parts of fatty alcohol; 11 parts of ethylene oxide; 42 parts of phosphorus pentoxide; 2 parts of potassium hydroxide; 5 parts of deionized water.

[0044] The above-mentioned manufacture method for the antistatic agent of polyester elastic finish described in the present embodiment comprises following production steps:

[0045] The first step: fatty alcohol and ethylene oxide synthesize fatty alcohol polyoxyethylene ether;

[0046] The second step: fatty alcohol polyoxyethylene ether and phosphorus pentoxide synthesize fatty alcohol polyoxyethylene ether phosphate;

[0047] The third step: fatty alcohol polyoxyethylene ether phosphate and ethylene oxide to synthesize fatty alcohol polyoxyethylene ether phosphate polyoxyethylene;

[0048] The fourth step: Fatty alcohol polyoxyethylene ether polyoxyethylene phosphate and potassium hyd...

Embodiment 2

[0067] The antistatic agent for polyester elastic finish described in this embodiment, by weight, comprises the following materials:

[0068] 36 parts of fatty alcohol; 10 parts of ethylene oxide; 48 parts of phosphorus pentoxide; 3 parts of potassium hydroxide; 3 parts of deionized water.

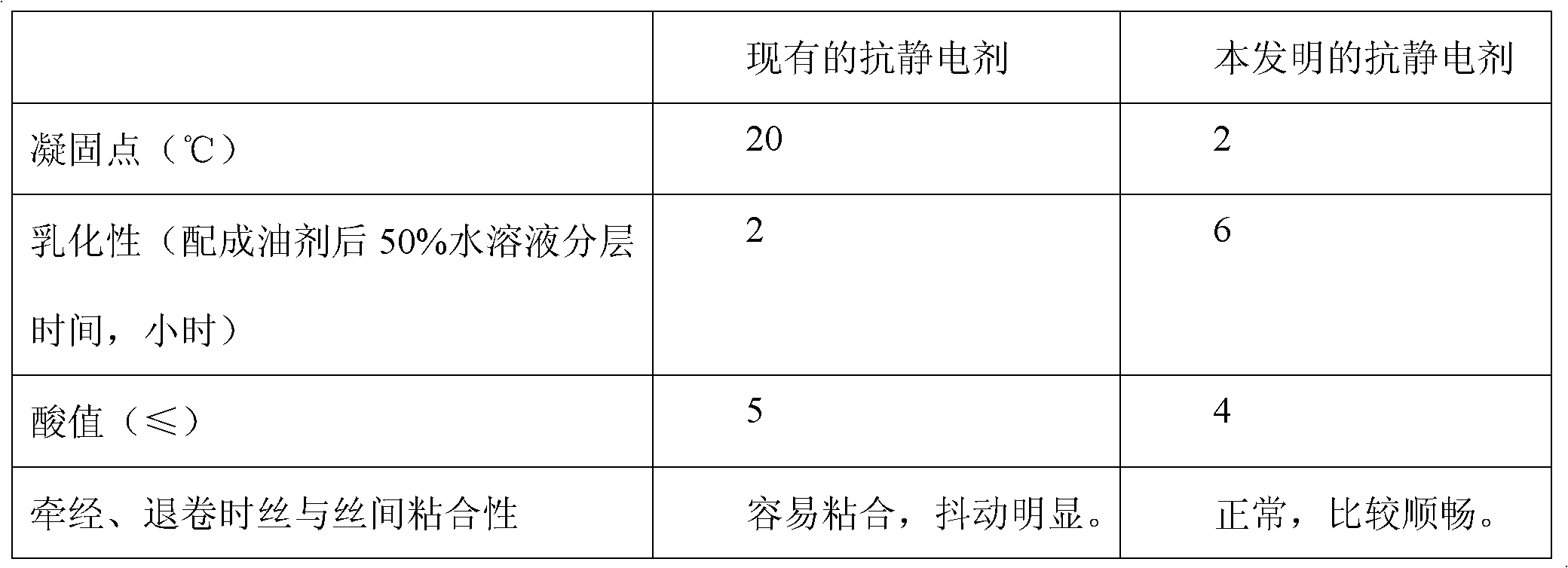

[0069] Its manufacture method is the same as embodiment 1, and the difference between the high-efficiency antistatic agent and existing antistatic agent produced by the present embodiment is as follows:

[0070]

[0071]

Embodiment 3

[0073] The antistatic agent for polyester elastic finish described in this embodiment, by weight, comprises the following materials:

[0074] 31 parts of fatty alcohol; 12 parts of ethylene oxide; 50 parts of phosphorus pentoxide; 3 parts of potassium hydroxide; 4 parts of deionized water.

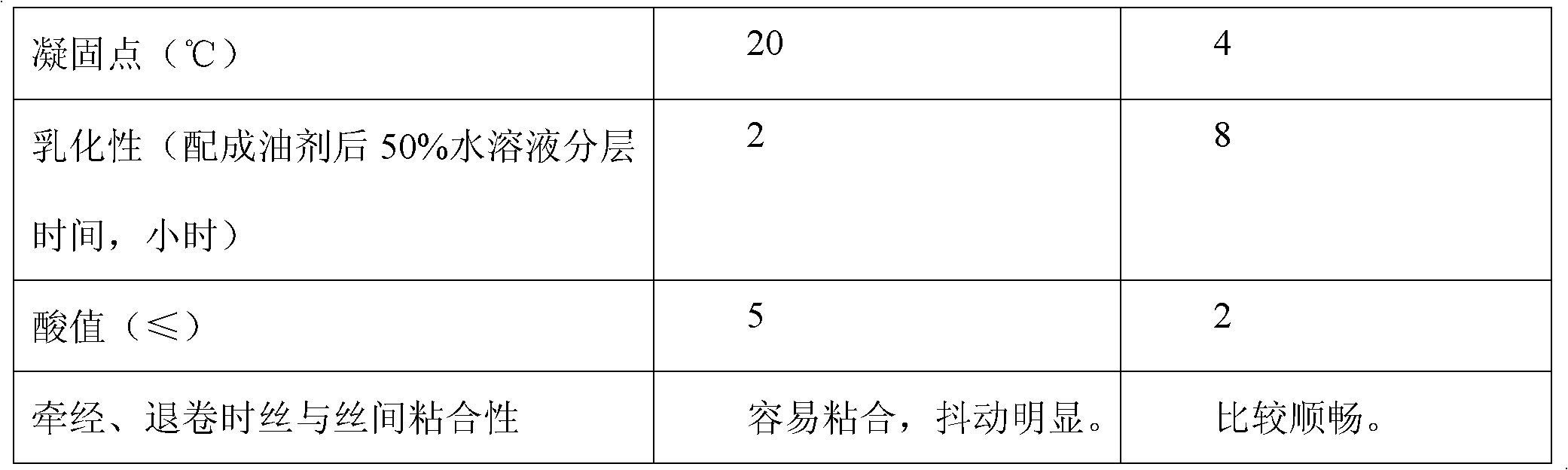

[0075] Its manufacture method is the same as embodiment 1, and the difference between the high-efficiency antistatic agent and existing antistatic agent produced by the present embodiment is as follows:

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com