Magnetic silicon dioxide microspheres modified with diethylaminoethyl and preparation method and application thereof

A technology of diethylaminoethyl and silicon dioxide, which is used in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problem of low ability of magnetic spheres to bind nucleic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

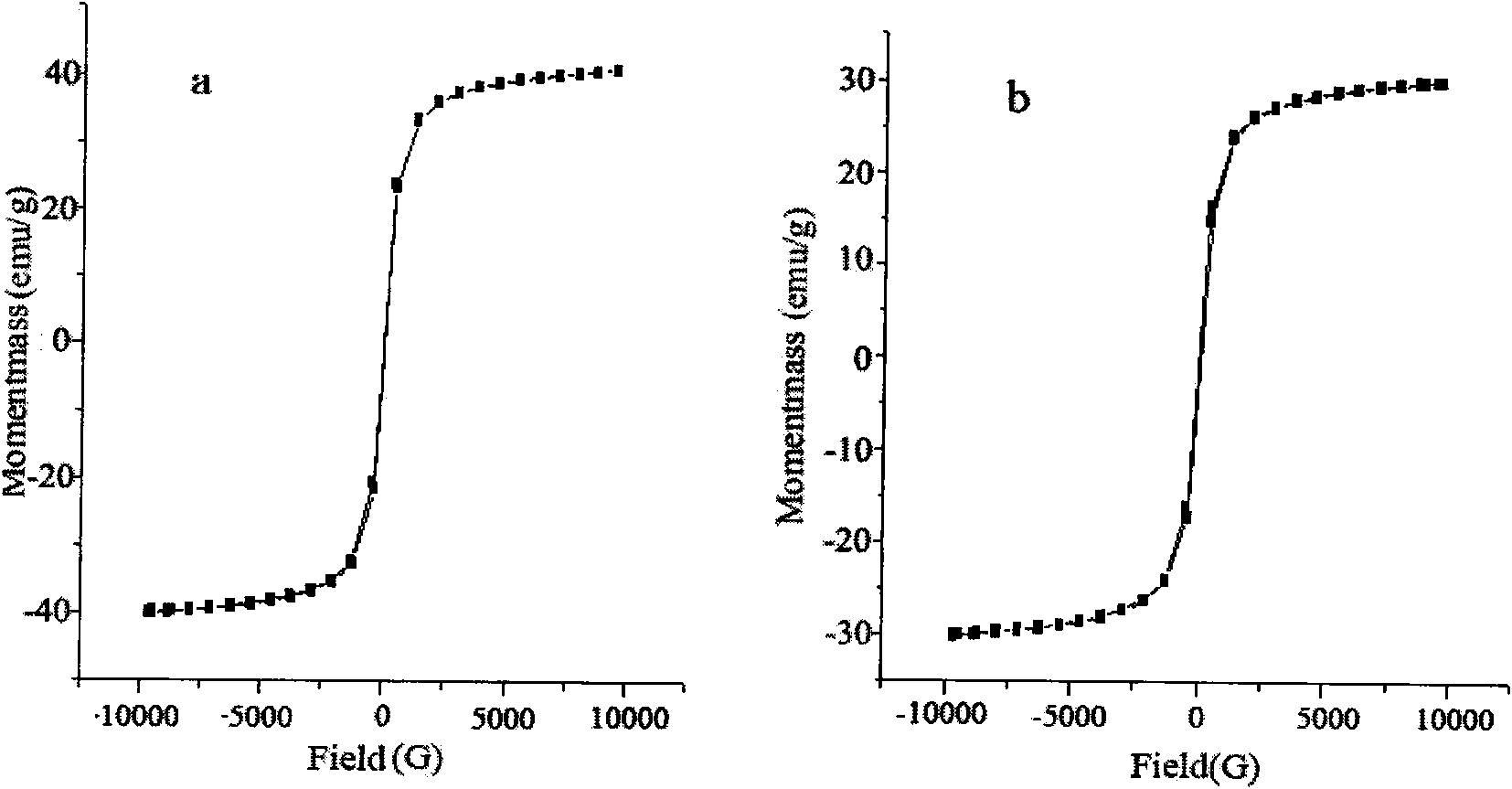

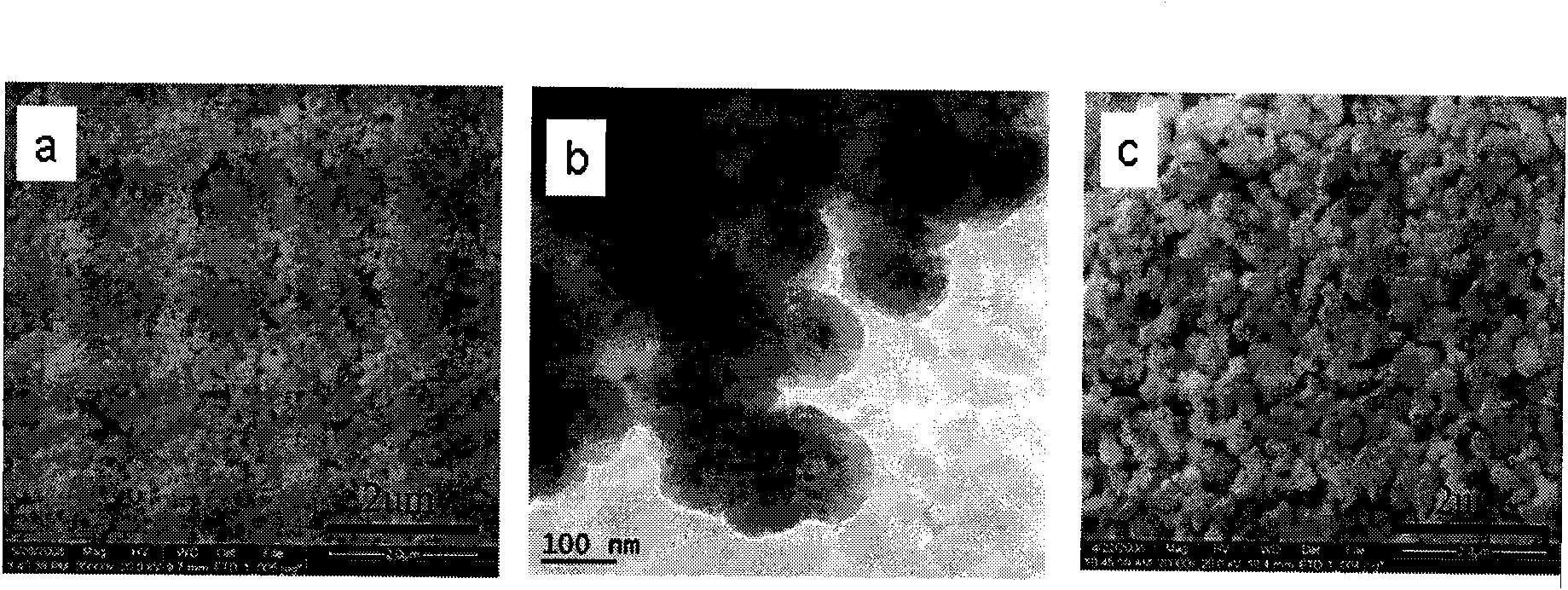

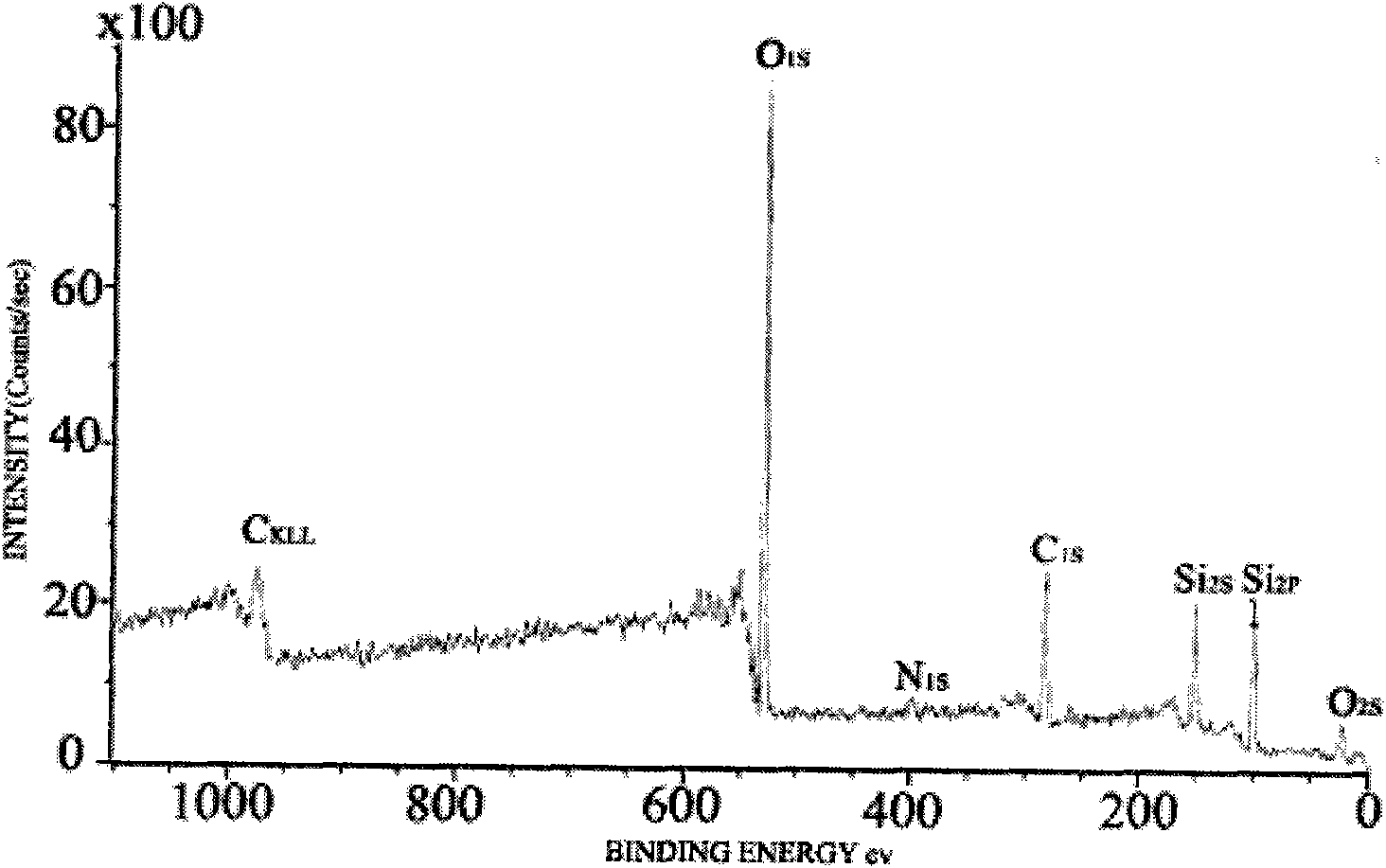

[0081] 1. Preparation of magnetic silica microspheres

[0082] Take 7.2892g cetyltrimethylammonium bromide and 109.3g toluene into the four-necked flask, stir evenly with a mixer at 1000 rpm, add 0.329g FeCl 2 ·4H 2 O and 0.987g FeCl 3 ·6H 2 O was dissolved in 9.4397g secondary water to prepare an aqueous solution with a concentration of 140g / L, and was added dropwise to the above mixture at 4 to 5 mL / h under the protection of 2 to 3 mL / min nitrogen, and stirring was continued for 4 to 6 hours at 800 rpm , Then add 2 mL of 25% ammonia water with a mass concentration of 25%, and continue stirring at 800 rpm for 2 hours. In the mixture, Fe3O4 nanoparticles are formed. Slowly add 9.79 mL of ethyl orthosilicate and stir at 800 rpm for reaction. Adjust the pH to 8, add 2~3mL / h of ethyl orthosilicate for 1 hour, stop the nitrogen protection, stir at 800 rpm, and age for 5 days at room temperature and pressure. Add 16.4g of ethanol to the product to Centrifuge at 2000 rpm for 40 minutes...

Embodiment 2

[0088] 1. Preparation of magnetic silica microspheres

[0089] Take 7.2892g cetyltrimethylammonium bromide and 87.47g toluene into a four-necked flask, stir evenly with a mixer at 1000 rpm, and add 0.305g FeCl 2 ·4H 2 O and 0.916g FeCl 3 ·6H 2 O was dissolved in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 130g / L, and added dropwise to the above mixture at 4 to 5 mL / h under the protection of 2 to 3 mL / min of nitrogen, and continued stirring at 800 rpm for 4 to 6 hours , Then add 1.15mL of 25% ammonia water with a mass concentration of 800 rpm and continue stirring for 2 hours. In the mixture, Fe3O4 nanoparticles are formed. Slowly add 6.78mL of ethyl orthosilicate and stir at 800 rpm. For the reaction, adjust the pH to 8, and add 2 to 3 mL / h of ethyl orthosilicate for 1 hour, stop the nitrogen protection, stir at 800 rpm, and age at room temperature and pressure for 5 days. Add ethanol 14.58g to the product Centrifuge at 2000 rpm for 40 minute...

Embodiment 3

[0095] 1. Preparation of magnetic silica microspheres

[0096] Take 7.2892g cetyltrimethylammonium bromide and 145.784g toluene into the four-necked flask, stir evenly with a mixer at 1000 rpm, add 0.354g FeCl 2 ·4H 2 O and 1.060g FeCl 3 ·6H 2 O was dissolved in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 150g / L, and added dropwise to the above mixture at 4 to 5 mL / h under the protection of 2 to 3 mL / min of nitrogen, and continued stirring at 800 rpm for 4 to 6 hours , Then add 2.28 mL of 25% ammonia water with a mass concentration of 800 rpm and continue to stir for 2 hours. In the mixture, Fe3O4 nanoparticles are formed. Slowly add 11.76 mL of ethyl orthosilicate and stir at 800 rpm. After the reaction, adjust the pH to 8, add 2-3 mL / h of ethyl orthosilicate for 1 hour, stop the nitrogen protection, stir at 800 rpm, and age at room temperature and pressure for 5 days. Add ethanol 18.223 to the product. Centrifuge at 2000 rpm for 40 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com