Method for preparing magnetic silica microspheres with surfaces modified by cations

A technology of silica and surface modification, which is applied in the preparation of silica, silica, and test samples, etc., can solve the problems of nucleic acid loss, time-consuming and labor-intensive nucleic acid purification process, etc., and achieve large amount of nucleic acid, simple operation, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

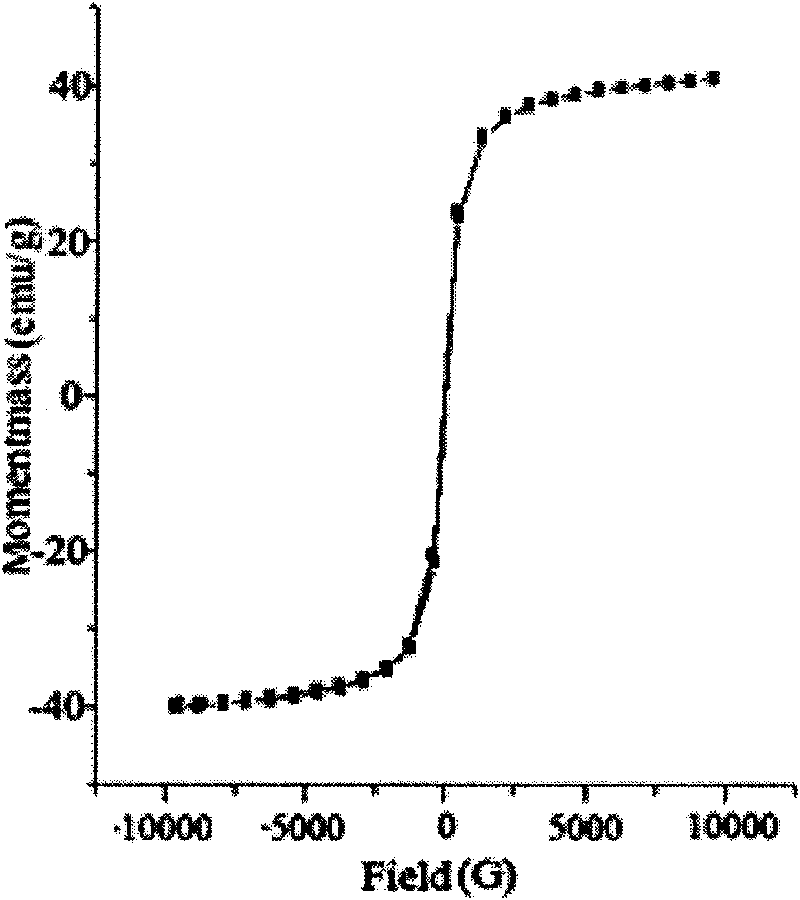

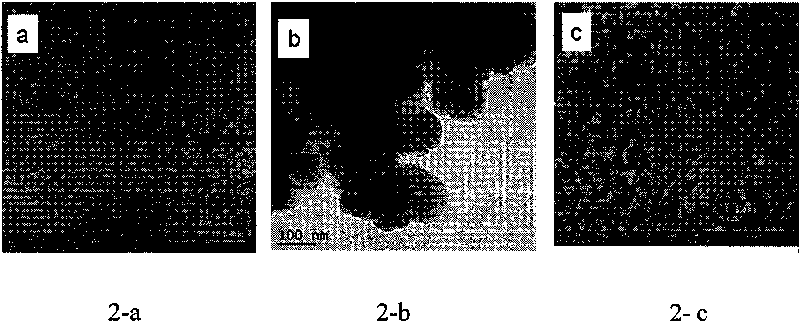

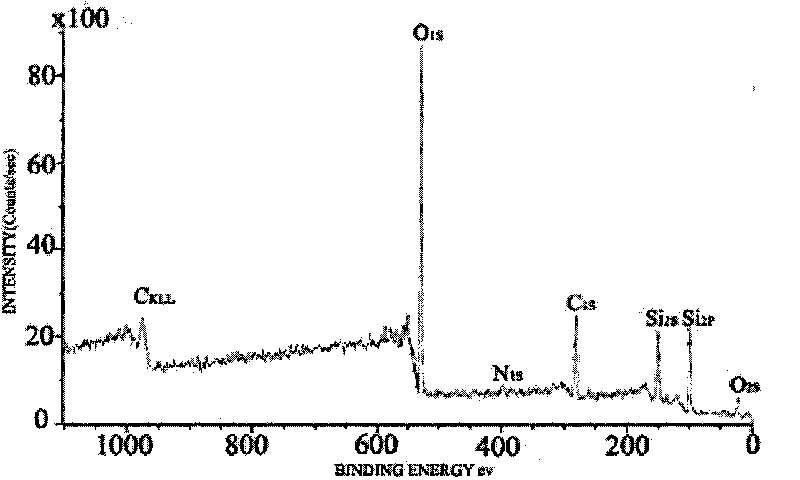

[0050] Example 1 Preparation of magnetic silica microspheres with surface-modified histidine

[0051] 1. Preparation of Magnetic Silica Microspheres

[0052] Take 7.2892g of cetyltrimethylammonium bromide and 109.3g of toluene into the four-necked flask, stir evenly with a stirrer at 1000 rpm, mix 0.329g of FeCl 2 4H 2 O with 0.987g FeCl 3 ·6H 2 Dissolve O in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 140g / L, add dropwise to the above mixture at 4-5mL / h under nitrogen protection at 2-3mL / min, and continue stirring at 800 rpm for 4-6 hours , then add 2 mL of ammonia water with a mass concentration of 25%, and continue to stir at 800 rpm for 2 hours. In the mixture, iron ferric oxide nanoparticles are formed, slowly add 9.79 mL of tetraethyl orthosilicate, and stir at 800 rpm. Adjust the pH to 8, 1 hour after adding tetraethyl orthosilicate dropwise at 2-3mL / h, stop the nitrogen protection, stir at 800 rpm, age for 5 days at normal temp...

Embodiment 2

[0057] Example 2 Preparation of magnetic silica microspheres with surface-modified polyhistidine

[0058] 1. Preparation of Magnetic Silica Microspheres

[0059] Take 7.2892g of cetyltrimethylammonium bromide and 109.3g of toluene into the four-necked flask, stir evenly with a stirrer at 1000 rpm, mix 0.329g of FeCl 2 4H 2 O with 0.987g FeCl 3 ·6H 2 Dissolve O in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 140g / L, add dropwise to the above mixture at 4-5mL / h under nitrogen protection at 2-3mL / min, and continue stirring at 800 rpm for 4-6 hours , then add 2 mL of ammonia water with a mass concentration of 25%, and continue to stir at 800 rpm for 2 hours. In the mixture, iron ferric oxide nanoparticles are formed, slowly add 9.79 mL of tetraethyl orthosilicate, and stir at 800 rpm. Adjust the pH to 8, 1 hour after adding tetraethyl orthosilicate dropwise at 2-3mL / h, stop the nitrogen protection, stir at 800 rpm, age for 5 days at normal ...

Embodiment 3

[0064] Embodiment 3 prepares the magnetic silica microsphere of surface modification imidazole

[0065] 1. Preparation of Magnetic Silica Microspheres

[0066] Take 7.2892g of cetyltrimethylammonium bromide and 109.3g of toluene into the four-necked flask, stir evenly with a stirrer at 1000 rpm, mix 0.329g of FeCl 2 4H 2 O with 0.987g FeCl 3 ·6H 2 Dissolve O in 9.4397g of secondary water to prepare an aqueous solution with a concentration of 140g / L, add dropwise to the above mixture at 4-5mL / h under nitrogen protection at 2-3mL / min, and continue stirring at 800 rpm for 4-6 hours , then add 2 mL of ammonia water with a mass concentration of 25%, and continue to stir at 800 rpm for 2 hours. In the mixture, iron ferric oxide nanoparticles are formed, slowly add 9.79 mL of tetraethyl orthosilicate, and stir at 800 rpm. Adjust the pH to 8, 1 hour after adding tetraethyl orthosilicate dropwise at 2-3mL / h, stop the nitrogen protection, stir at 800 rpm, age for 5 days at normal te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com