Process method for processing titanium nitride residues on aluminum welding pad

A process method, titanium nitride technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

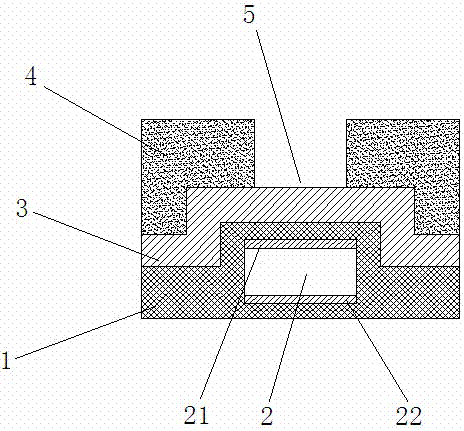

[0030] Such as Figure 3A As shown, in a specific embodiment of the present invention, a process method for treating titanium nitride residues on an aluminum pad includes: a substrate 1, a metal layer 2 provided in the substrate 1, a substrate 1 and a metal layer A top metal barrier layer 21 is provided between the upper surface of the layer 2, a bottom metal barrier layer 22 is provided between the substrate 1 and the lower surface of the metal layer 2, a barrier layer 3 is provided on the upper surface of the substrate 1, and the barrier layer 3 is deposited. The photoresist layer 4, the photoresist layer 4 is located directly above the metal layer 2 and hollowed out 5, which includes the following process steps:

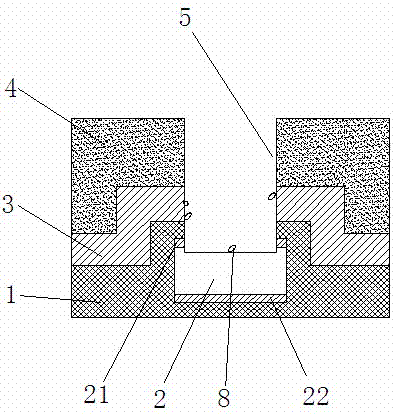

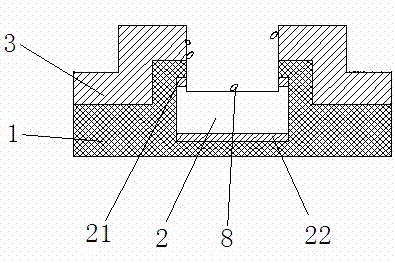

[0031] Such as Figure 3B As shown, in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com