Compound strengthening method of small hole in ultrahigh strength steel part

A technology for ultra-high-strength steel and parts, which is applied in the improvement field of surface strengthening methods, which can solve problems such as insufficient strengthening effect, high roughness, and scratches on the hole wall, and achieve the depth of the orifice extrusion strengthening layer and the feasibility of process implementation Good, the effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Composite strengthening of Φ14mm holes

[0018] 1. Hole rounding

[0019] The orifice is manually rounded with a reamer, and the rounding radius is 1.0mm.

[0020] 2. Hole shot peening

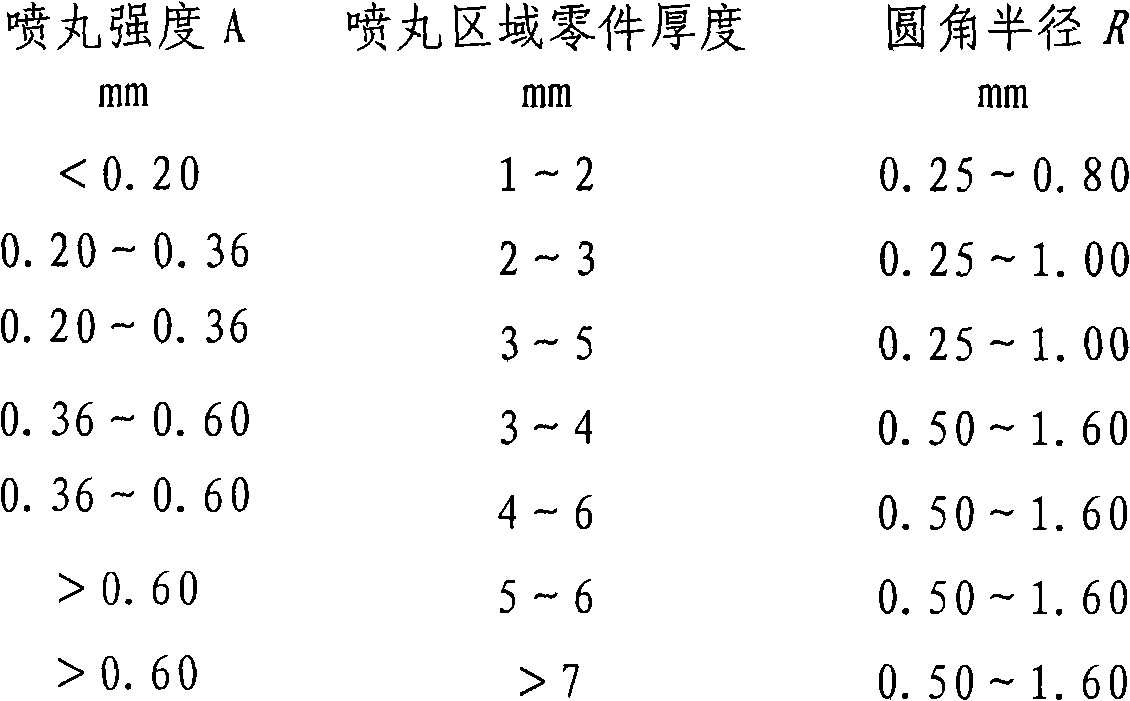

[0021] Process selection:

[0022] (1) projectile

[0023] Projectile type: cast steel shot

[0024] Projectile size: φ0.4mm

[0025] (2) Shot peening method: Spray the hole wall directly by using the hair gun rotation and feeding method

[0026] (3) Shot peening intensity: 0.25A

[0027] (4) Shot peening coverage: 100%

[0028] (5) Spray angle (the angle between the nozzle and the tangent of the sprayed surface): 85°

[0029] 3. Orifice extrusion

[0030] Use a hydraulic press and a self-made orifice extrusion head to extrude and strengthen the orifice, and the extrusion load is 21MPa.

[0031] After using the above-mentioned process steps to strengthen the small hole on the tensile-tension fatigue sample with the middle opening of A-100 steel, the strengthening ef...

Embodiment 2

[0036] Example 2: Composite strengthening of Φ12mm holes

[0037] 1. Hole rounding

[0038] The orifice is manually rounded with a reamer, and the rounding radius is 1.0 mm.

[0039] 2. Hole shot peening

[0040] Process selection:

[0041] (1) projectile

[0042] Projectile type: cast steel shot

[0043] Projectile size: φ0.4mm

[0044] (2) Shot peening method: Spray the hole wall directly by using the hair gun rotation and feeding method

[0045] (3) Shot peening intensity: 0.20A

[0046] (4) Shot peening coverage: 100%

[0047] (5) Spray angle (the angle between the nozzle and the tangent of the sprayed surface): 85°

[0048] 3. Orifice extrusion

[0049] Use a hydraulic press and a self-made orifice extrusion head to extrude and strengthen the orifice, and the extrusion load is 21MPa.

[0050] After using the above-mentioned process steps to strengthen the small hole on the tensile-tension fatigue sample with the middle opening of A-100 steel, the strengthening e...

Embodiment 3

[0055] Example 3: Composite strengthening of Φ10mm holes

[0056] 1. Hole rounding

[0057] The orifice is manually rounded with a reamer, and the rounding radius is 1.0 mm.

[0058] 2. Hole shot peening

[0059] Process selection:

[0060] (1) projectile

[0061] Projectile type: cast steel shot

[0062] Projectile size: φ0.2mm

[0063] (2) Shot peening method: Spray the hole wall directly by using the hair gun rotation and feeding method

[0064] (3) Shot peening intensity: 0.20A

[0065] (4) Shot peening coverage: 100%

[0066] (5) Spray angle (the angle between the nozzle and the tangent of the sprayed surface): 85°

[0067] 3. Orifice extrusion

[0068]Using a hydraulic press, a self-made orifice extrusion head is used to extrude and strengthen the orifice, and the extrusion load is 16MPa.

[0069] After using the above-mentioned process steps to strengthen the small hole on the tensile-tension fatigue sample with the middle opening of A-100 steel, the strengthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com