Preparation method of dispersant modified iron nanoparticles

A dispersant and nano-iron technology, applied in the field of preparation of nano-iron particles, can solve the problems of dechlorination system promotion or inhibition, insufficient use of surfactants, control of nano-particle size, etc., and achieve easy engineering. Application, improved stability, enhanced surface attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of polymethyl methacrylate PMMA dispersed modified nano-iron particles and their removal of various chlorinated organics in water, the specific contents are as follows:

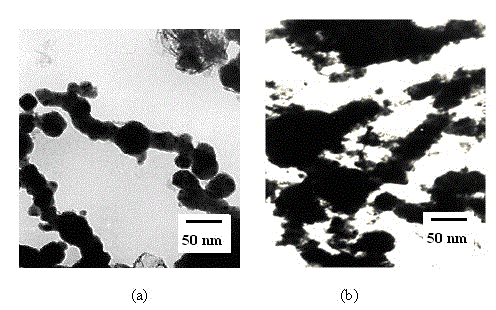

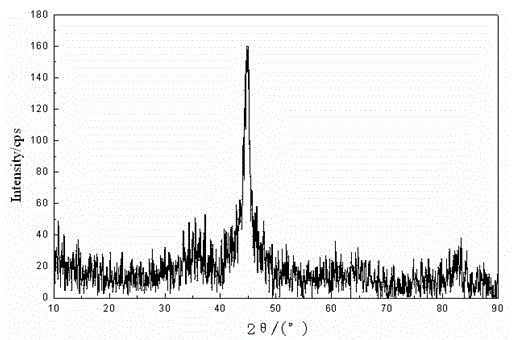

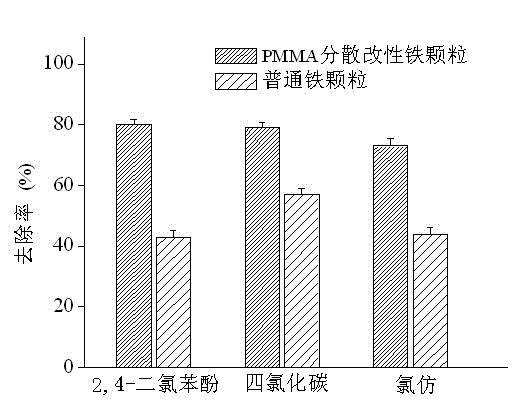

[0036] (1) Preparation of PMMA dispersed modified iron nanoparticles and its dechlorination effect

[0037] Get the anisole solution 10mL and the 200mL concentration that is 7% PMMA by mass percent and be 0.1mol / L FeSO 4 After the solution is mixed, stir for 10 minutes, and add an excess of 0.2mol / L KBH dropwise to the above mixed solution 4 Add the solution to 200mL and stir. After the dropwise addition, delay stirring for 15 minutes until the reaction is complete, filter and drain through a vacuum filtration device, wash with deionized water for 3 times, and filter until dry, and then wash with absolute ethanol for 3 times , washed once with acetone, dried and put into a vacuum drying oven at 100°C to dry for 6 hours, ground under nitrogen, sealed and stored to obtain PMMA dis...

Embodiment 2

[0043] Embodiment 2: the preparation of PMMA dispersion modified nano-palladium / iron particles and its removal of various chlorinated organics in water, the specific contents are as follows:

[0044] (1) Preparation of PMMA dispersed modified nano-palladium / iron bimetallic particles and its dechlorination effect

[0045] Get the anisole solution 10mL and 200mL concentration that is 8% PMMA of mass percent and be 0.1mol / L FeSO 4 After the solution is mixed, stir for 10 minutes, and add an excess of 0.2mol / LKBH dropwise to the above mixed solution 4 Add the solution to 200mL and stir. After the dropwise addition, delay stirring for 15 minutes until the reaction is complete, filter and drain through a vacuum filter device, wash with deionized water for 3 times, and pour the zero-valent nano-iron particles obtained by draining into palladium acetate In the ethanol solution, react under magnetic stirring for 30min, place the reaction product in a sand core filter device and filter...

Embodiment 3

[0050] Example 3: Preparation of CTAB dispersed modified nano-nickel / iron particles and their removal of various chlorinated organics in water, the specific contents are as follows:

[0051] (1) Preparation of nano-nickel / iron bimetallic particles modified by CTAB dispersion and its dechlorination effect

[0052] Take 10mL of 10% cetyltrimethylammonium bromide solution (with 70% ethanol as solvent) and 250mL of 0.15mol / L FeSO 4 After the solution is mixed, stir for 10 minutes, and add an excess of 0.3mol / LKBH dropwise to the above mixed solution 4 Add the solution to 200mL and stir. After the dropwise addition, delay stirring for 12 minutes until the reaction is complete, filter and drain through a vacuum filter device, wash with deionized water twice, and immerse the zero-valent nano-iron particles obtained by draining to a concentration of 120mg / L nickel chloride (NiCl 2 ) solution, reacted for 30 minutes under magnetic stirring, put the reaction product in a sand core fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com