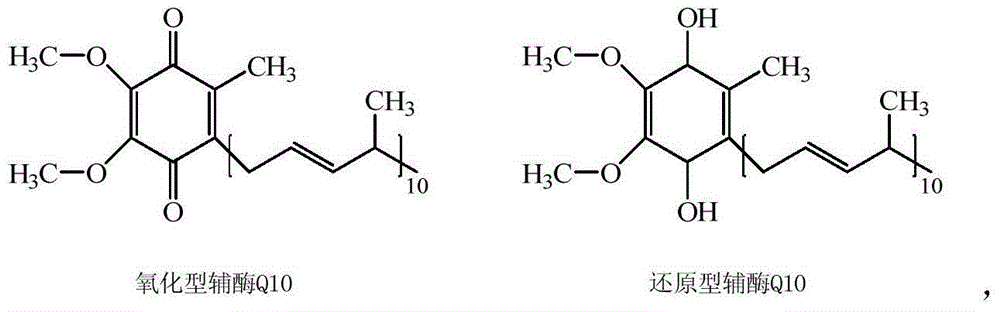

Preparation method for reductive coenzyme Q10

A reduced and oxidized coenzyme technology, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of reduced coenzyme Q10, such as easy deterioration, inconvenient workshop operation, and potential safety hazards, and achieve reduction Quick response, safe and reliable product, easy control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 10g of oxidized coenzyme Q10, add 100ml of n-hexane, 100ml of ethanol, and 10ml of distilled water, heat up to 50°C and stir to dissolve, protect with nitrogen, add 4g of stannous chloride, 0.5ml of concentrated hydrochloric acid, and detect after 3 hours of reaction. After reaching the oxidized coenzyme Q10, add 100ml of n-hexane to stir and extract, after standing for stratification, wash the upper layer with 100ml of distilled water, then wash with 100ml of alkali solution, then wash with 100ml of distilled water, finally distill off the solvent n-hexane, add 100ml of ethanol and stir After dissolving, the reduced coenzyme Q10 was crystallized with a purity of 98.4% and a yield of 94%. The lower aqueous solution is electrochemically reduced to obtain a transparent stannous chloride dilute hydrochloric acid solution with a tin recovery rate of 95%. The concentrated stannous chloride continues to reduce the oxidized coenzyme Q10 for repeated use and continuous reac...

Embodiment 2

[0038] Take 20g of oxidized coenzyme Q10, add 300ml of ethanol, heat up to 50°C and stir to dissolve, protect with nitrogen, add 6g of stannous chloride and 0.5ml of concentrated hydrochloric acid, and test after 2 hours of reaction. When almost no oxidized coenzyme Q10 can be detected, The purity of reduced coenzyme Q10 was 95% and the yield was 92%. The mother liquor is directly electrochemically reduced to obtain a stannous chloride-containing solution, and the oxidized coenzyme Q10 is continuously reduced for repeated use and continuous reaction.

Embodiment 3

[0040] Take 10g of oxidized coenzyme Q10, add 100ml of cyclohexane, 100ml of methanol, and 5ml of distilled water, heat up to 60°C and stir to dissolve, protect with nitrogen, add 4g of stannous chloride, 0.5ml of concentrated hydrochloric acid, and detect after 2 hours of reaction. After less than oxidized coenzyme Q10, add 100ml of cyclohexane to stir and extract, let it stand for stratification, go to the lower layer, wash with 100ml of distilled water, then wash with 100ml of alkali solution, then wash with 100ml of distilled water, and finally distill off the solvent cyclohexane, After adding 100ml of ethanol and stirring to dissolve, the reduced temperature was crystallized to obtain reduced coenzyme Q10 with a purity of 98.2% and a yield of 93%. The lower aqueous solution is electrochemically reduced to obtain a transparent stannous chloride dilute hydrochloric acid solution with a tin recovery rate of 95%. The concentrated stannous chloride continues to reduce the oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com