Preparation method of anti-yellowing agent HN-150

An anti-yellowing agent and solvent technology, which is applied in the field of chemical intermediate technology, can solve the problems of low product purity, difficult recovery of solvents, and easy environmental pollution, and achieve the effects of high purity, low equipment requirements, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

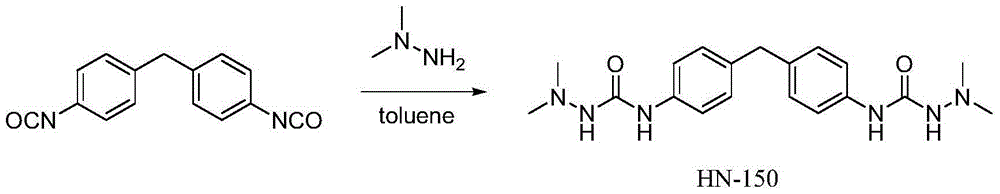

[0020] The invention provides a preparation method of spandex anti-yellowing agent HN-150, comprising the following steps:

[0021] a. respectively dissolve unsymmetrical dimethylhydrazine and diphenylmethane diisocyanate in the organic solvent under the state of stirring; then mix the two and continue to stir the reaction;

[0022] b. After the reaction finishes, filter the mixed solution in a;

[0023] c. Dry the solid obtained by filtering in b.

[0024]

Embodiment 1

[0027] In a 2L three-necked flask, mix 66.0g of unsymmetrical dimethylhydrazine in 1000mL of ethyl acetate. Slowly add 125.0 g of diphenylmethane diisocyanate into the three-necked flask in batches. After the addition was complete, stirring was continued for 2 hours. The reaction solution was suction-filtered to obtain a crude product with a wet weight of about 360 g. The crude product obtained above was dried in an oven to obtain about 175.0 g of white powder with a yield of 92% (the purity was 97% as detected by HPLC).

[0028] The ethyl acetate in the above-mentioned filtrate is distilled again, and the ethyl acetate obtained can continue to be reused.

Embodiment 2

[0030] In a 1000mL three-necked flask, mix 100.0g of diphenylmethane diisocyanate in 600mL of ethyl acetate. Mix 53.0g of unsymmetrical dimethylhydrazine in 160mL of ethyl acetate, and slowly add it into the three-necked flask. After the addition was complete, stirring was continued for 2 hours. The reaction solution was suction-filtered to obtain a crude product with a wet weight of about 280 g. The crude product obtained above was dried in an oven to obtain about 140.0 g of white powder with a yield of 92% (the purity was 97% as detected by HPLC).

[0031] The ethyl acetate in the above-mentioned filtrate is distilled again, and the ethyl acetate obtained can continue to be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com