Contact temperature measuring sensor, preparation method thereof, and cooking equipment

A technology of temperature measurement sensor and cooking equipment, which is applied to thermometers, instruments, thermometers, etc. that use electric/magnetic elements that are directly sensitive to heat, and can solve problems such as difficult precise temperature control, cumbersome process, and difficult intelligent cooking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

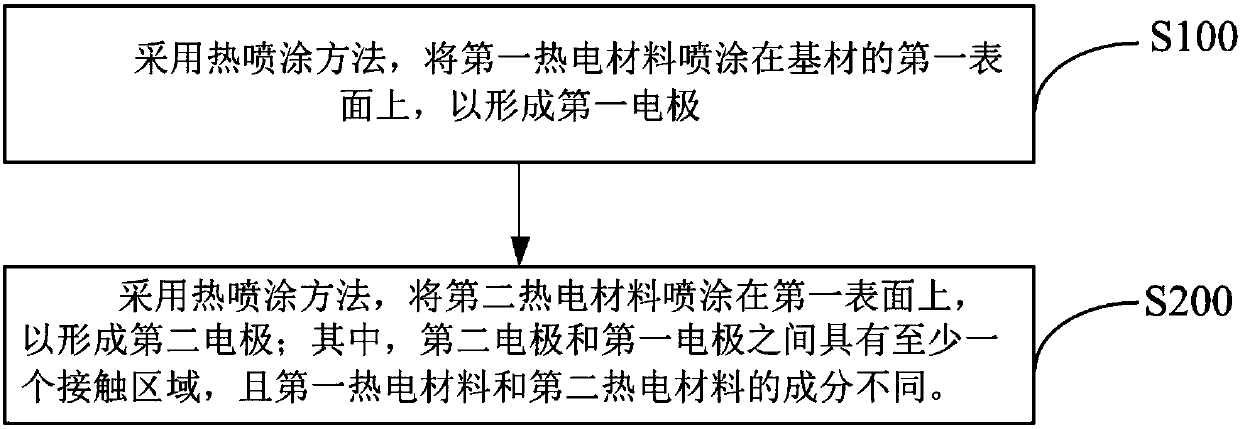

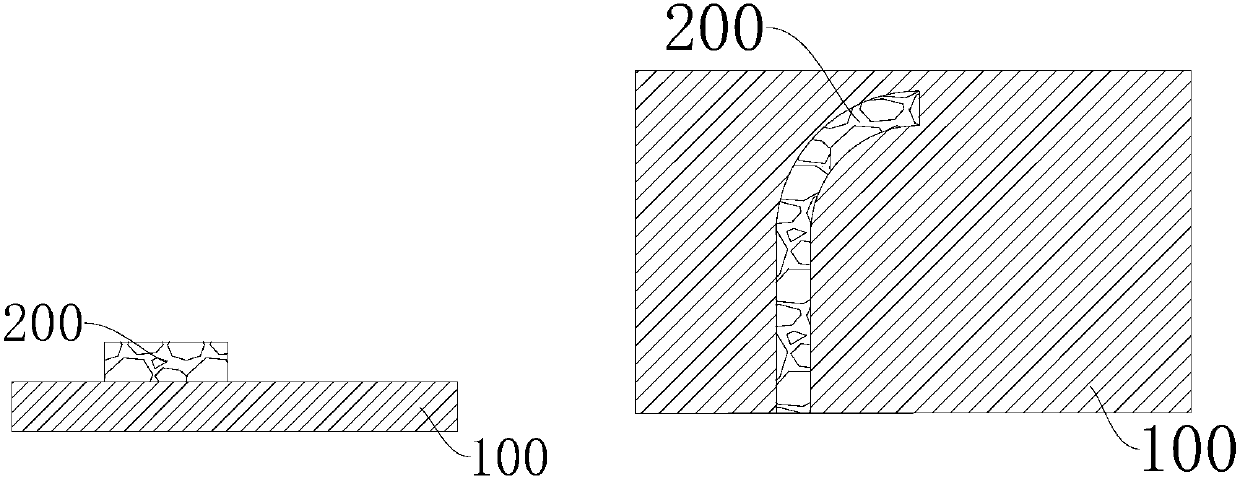

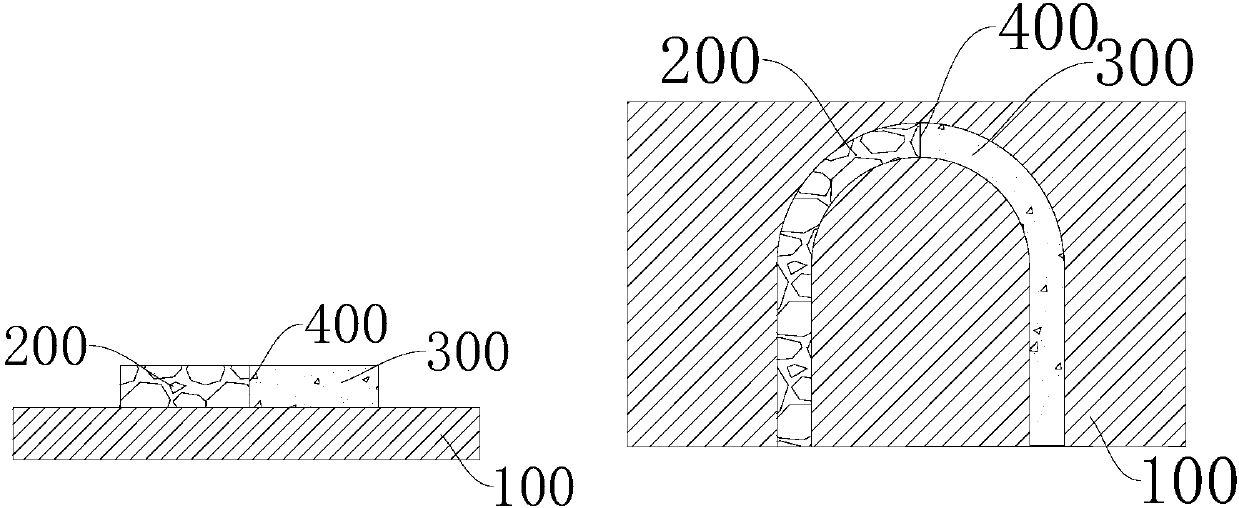

[0045] In one aspect of the present invention, the present invention provides a method for preparing a contact temperature sensor. According to an embodiment of the present invention, refer to figure 1 with Figure 2a to Figure 2c , The method includes the following steps:

[0046] S100: Using a thermal spraying method to spray the first thermoelectric material on the first surface of the substrate 100 to form the first electrode 200, see Figure 2a (in Figure 2a The middle left is a schematic diagram of the cross-sectional structure Figure 2a The middle right is a schematic diagram of the plane structure);

[0047] According to the embodiment of the present invention, the specific material type of the first thermoelectric material is not particularly limited. As long as the requirements are met, those skilled in the art can make flexible selections according to their needs. For example, they may include but not limited to platinum rhodium alloys and nickel-chromium alloys. , Iro...

Embodiment 1

[0130] Method for preparing contact temperature sensor

[0131] 1. The clean surface of the ceramic (100*200*1mm) is immersed in 10% hydrochloric acid and ultrasonic for 10 minutes, and then immersed in ethanol solvent for 20 minutes;

[0132] 2. Cover the first mask with the first electrode pattern hollowed out on the ceramic;

[0133] 3. Remove the oxidized part of the surface of the first wire (the composition is iron, the diameter is 1.2mm);

[0134] 4. The carrier gas is N 2 Under the conditions of, use arc spray equipment to spray the first wire on the ceramic covering the first mask. The spraying voltage is 40V, the current is 100A, the spraying distance is 400mm, the spraying air pressure is 0.4MPa, and the spray gun moving speed is 100mm / S, forming the first electrode of the contact temperature sensor, with an average thickness of 15μm and a resistance of 350Ω;

[0135] 5. Cover the second mask with the hollowed-out second electrode pattern on the ceramic, the hollowed-out pat...

Embodiment 2

[0140] Method for preparing contact temperature sensor

[0141] 1. The stainless steel alloy (200*200*1mm) is sandblasted with 80 mesh brown corundum, and then the surface is insulated;

[0142] 2. Cover the first mask plate with the first electrode pattern hollowed out on the stainless steel alloy whose surface has been insulated;

[0143] 3. Remove the first wire (the composition is Ni 90 Cr 10 , The diameter is 2.0mm) the oxidation part of the surface;

[0144] 4. The carrier gas is N 2 Under the conditions of, use the arc spray equipment to spray the first wire on the ceramic covering the first mask. The spraying voltage is 20V, the current is 100A, the spraying distance is 300mm, the spraying air pressure is 0.6MPa, and the spray gun moving speed is 100mm / S, forming the first electrode of the contact temperature sensor, with an average thickness of 35μm and a resistance of 150Ω;

[0145] 5. Cover the second mask plate with the hollowed-out second electrode pattern on the stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com