Method for rapidly densifying high-density full-gaseous phase pyrolytic carbon-based carbon/carbon composite materials

A carbon composite material, gas phase pyrolysis technology, applied in the field of carbon/carbon composite material preparation, can solve the problems affecting the density and uniformity, reduce the wear resistance of C/C materials, etc., and achieve convenient operation and simple process method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

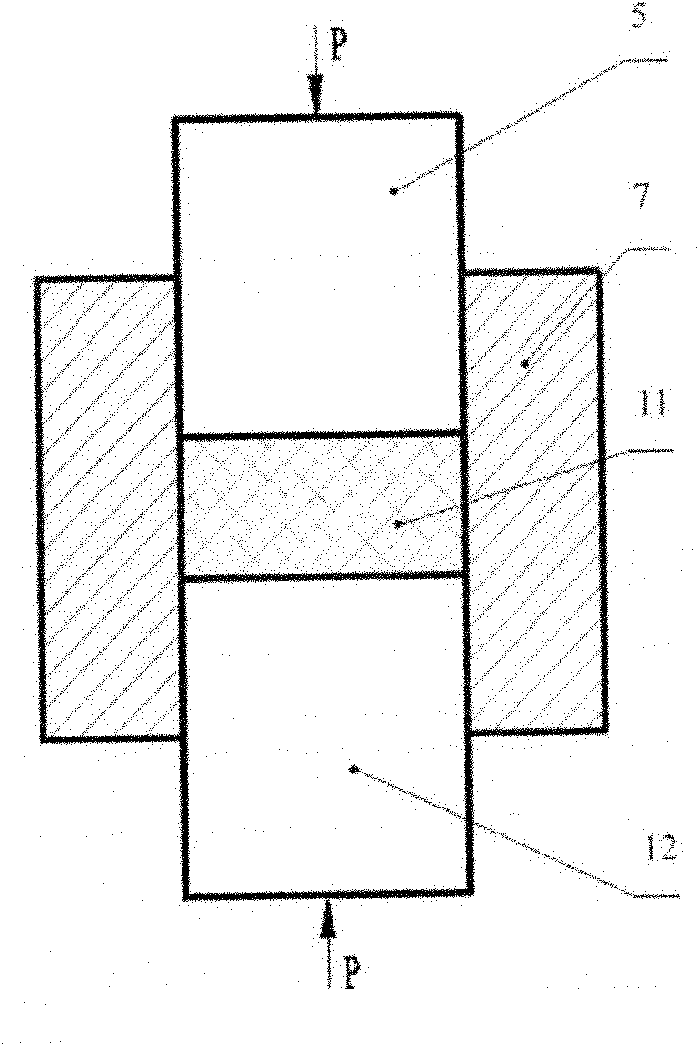

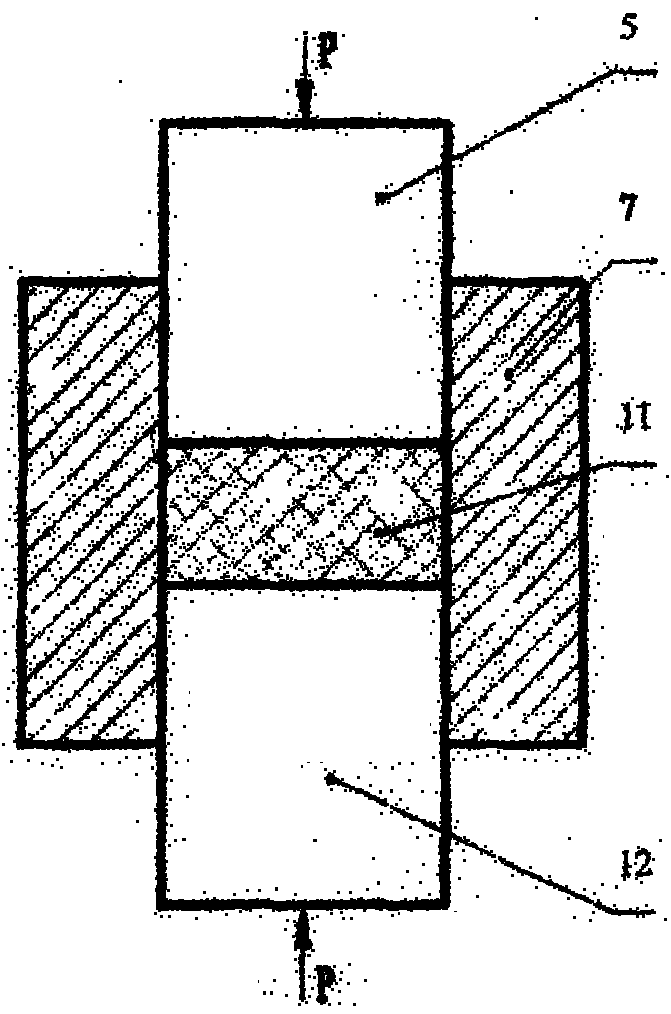

[0023] See attached figure 1 , using quasi-3D needle-punched carbon fiber integral felt, the felt body density is 0.3g / cm 3 , densified to 1.50g / cm by CVI 3, turn it, and the processed sample size is a cylindrical prefabricated body with an outer diameter of Φ50mm and a thickness of 25-30mm. The cylindrical mold 7 is used as a hot-pressing mold, and the mold is heated to 2300-2400℃ , loaded at a loading rate of 60-70MPa / h to 40-45MPa, controlling the strain in the pressing direction to 7%, and gradually unloading at an unloading rate of 30-40MPa / h after holding the pressure for 5-6 minutes; cooling with the furnace to obtain The main performance indicators of the test piece are as follows:

[0024] Density≥1.75g / cm 3

[0025] Graphitization degree≥72%

[0026] Thermal conductivity (⊥)≥45W / m·k

[0027] Shear strength (⊥)≥15MPa

[0028] Compressive strength (⊥)≥135MPa

Embodiment 2

[0030] See attached figure 1 , using quasi-3D needle-punched carbon fiber integral felt, the felt body density is 0.35g / cm 3 , densified to 1.60g / cm by CVI 3 , turn it, the size of the processed sample is a cylindrical prefabricated body with an outer diameter of Φ50mm and a thickness of 25-30mm. The cylindrical mold 7 is used as a hot pressing mold, and heated to 2500℃~2600℃ after the mold is installed. , loaded at a loading rate of 70-80MPa / h to 30-35MPa, the strain in the pressing direction is controlled to be 7%, and the pressure is maintained for 9-10 minutes and then gradually unloaded at an unloading rate of 30-40MPa / h; cooled with the furnace, the obtained The main performance indicators of the test piece are as follows:

[0031] Density≥1.80g / cm 3

[0032] Graphitization degree≥76%

[0033] Thermal conductivity (⊥)≥50W / m·k

[0034] Shear strength (⊥)≥13MPa

[0035] Compressive strength (⊥)≥135MPa

Embodiment 3

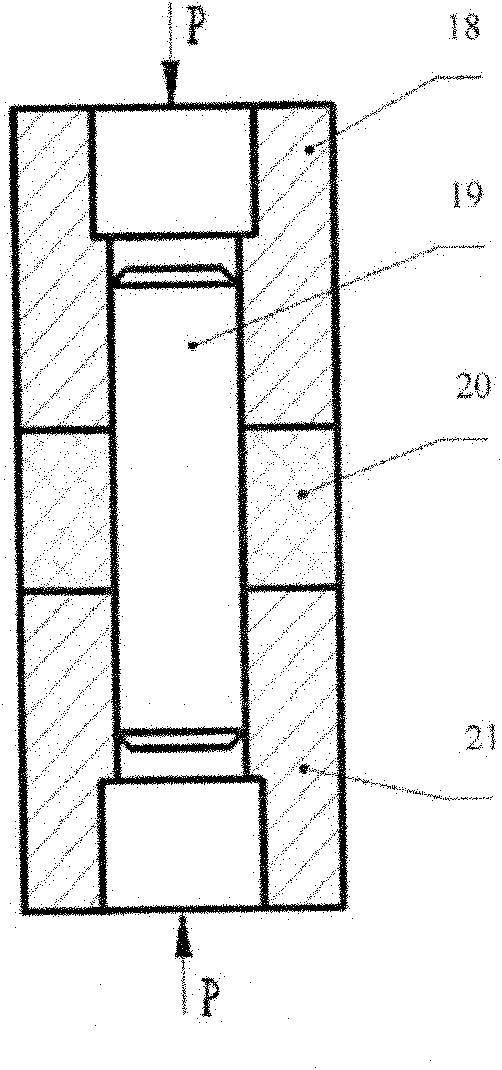

[0037] See attached figure 2 , using quasi-3D needle-punched carbon fiber integral felt, the felt body density is 0.4g / cm 3 , densified by CVI to 1.65g / cm 3 , turn it, and the size of the processed sample is an annular prefabricated body with an outer diameter of Φ50mm and a thickness of 25-30mm. The cylindrical mold 7 is used as a hot pressing mold, and the core is inserted in the ring of the test piece. Shaft 19 is molded and heated to 2600°C-2700°C, loaded to 45-50MPa at a loading rate of 90-100MPa / h, controlled to 7% strain in the pressing direction, and held at 30-40MPa / h for 7-8 minutes. The unloading rate is gradually unloaded; with the furnace cooling, the main performance indicators of the prepared test piece are as follows:

[0038] Density≥1.85g / cm 3

[0039] Graphitization degree ≥ 80%

[0040] Thermal conductivity (⊥)≥40W / m·k

[0041] Shear strength (⊥)≥12MPa

[0042] Compressive strength (⊥)≥130MPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com