Method for fast preparing translucent Li-alpha-SiAlON ceramic material

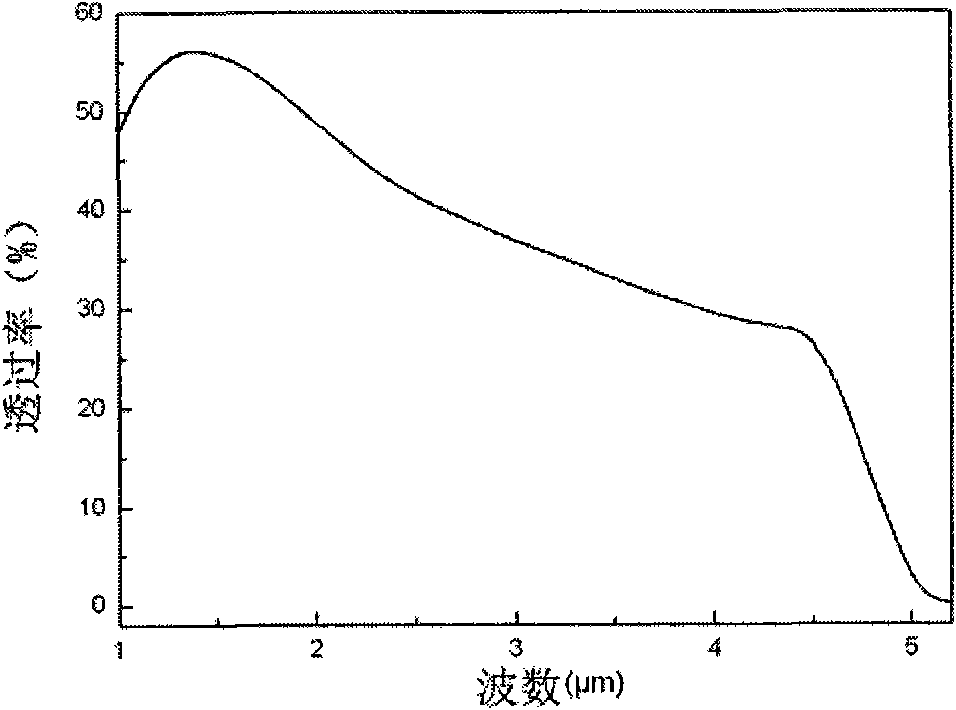

A ceramic material, translucent technology, applied in the field of translucent ceramic material preparation, can solve the problem of high sintering temperature, achieve the effect of low sintering temperature, excellent infrared light transmission performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

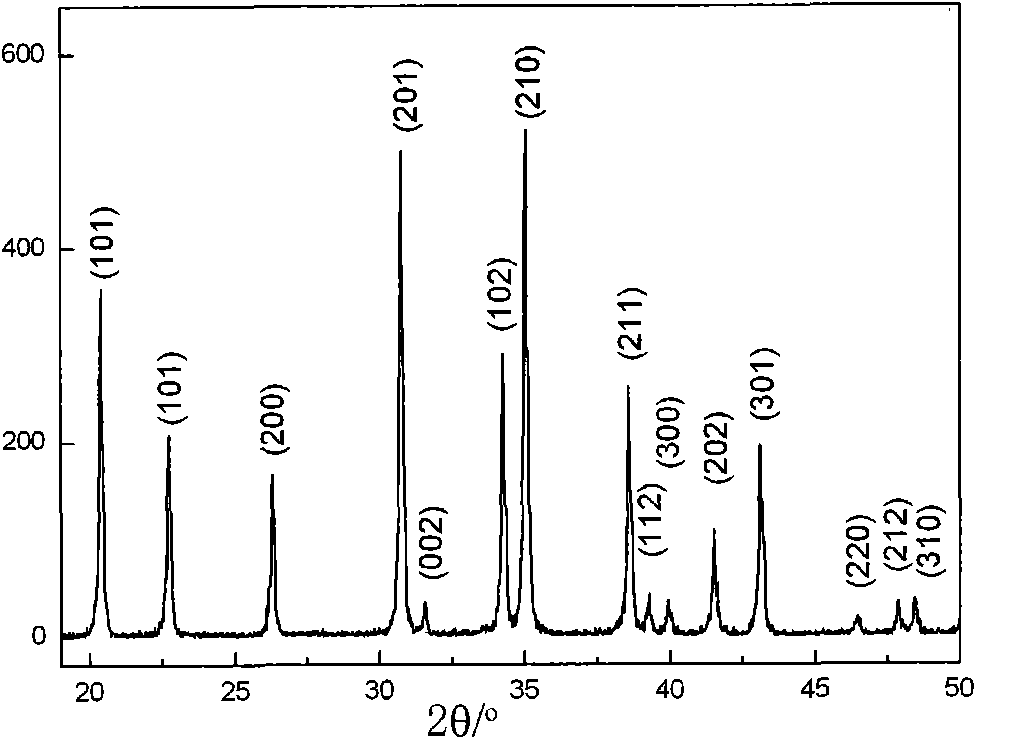

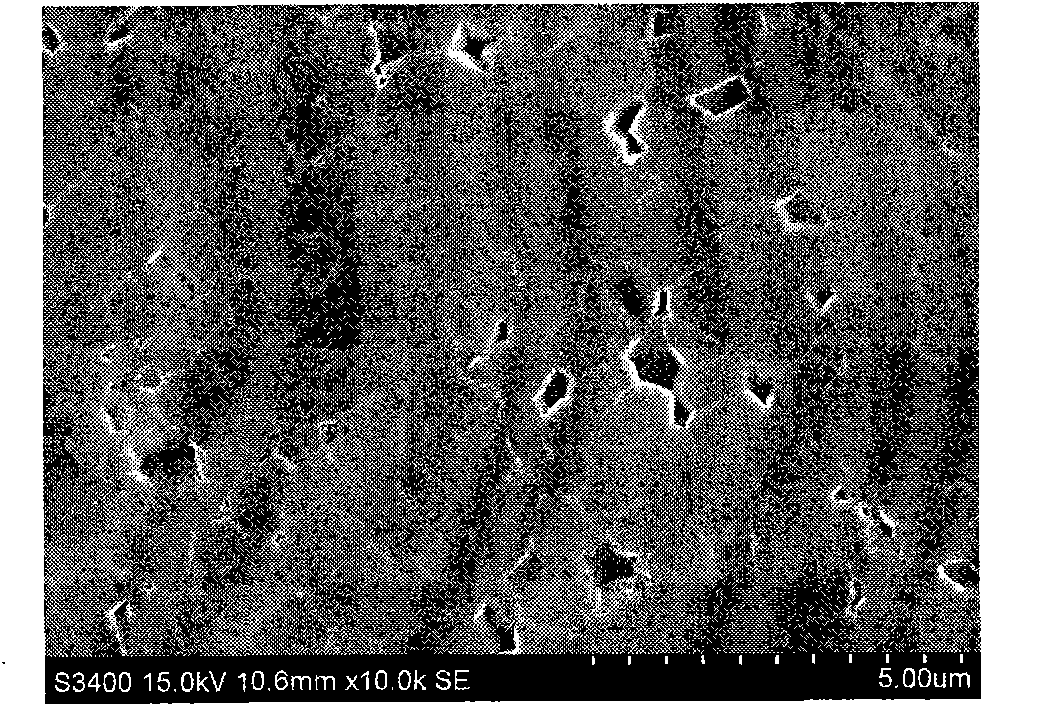

[0028] α-Si 3 N 4 , AlN, α-Al 2 o 3 , Li 2 CO 3 as raw material, according to Li m Si 12-m-n al m+n o n N 16-n The stoichiometric ratio of (m=1.0, n=1.5) selects α-Si with a total weight of 100g 3 N 4 , AlN, α-Al 2 o 3 , Li 2 CO 3 Raw materials, mixed in a plastic bottle, then with Si 3 N 4The ball is the ball milling medium, the ball-to-material ratio is 4:1, then add 500ml of absolute ethanol, and roll the ball mill for 24 hours to obtain the slurry; the slurry is evaporated to dryness in a rotary evaporator at 60°C, and then put into a vacuum drying oven to vacuum Dry for at least 24 hours, then take it out, grind for 20 minutes, and pass through a 100-mesh sieve to obtain the undersize; put the sieved undersize into a graphite mold with a diameter of 20mm, and then put it into a spark plasma sintering furnace, in N 2 Under the condition of gas protection and sintering pressure of 20Mpa, the heating rate was raised to 1000°C at a rate of 100°C / min, kept for...

Embodiment 2

[0034] α-Si 3 N 4 , AlN, α-Al 2 o 3 , Li 2 CO 3 as raw material, according to Li m Si 12-m-n Al m+n o n N 16-n The stoichiometric ratio of (m=1.2, n=1.2) selects α-Si with a total weight of 100g 3 N 4 , AlN, α-Al 2 o 3 , Li 2 CO 3 Raw materials, mixed in a plastic bottle, then with Si 3 N 4 The ball is the ball milling medium, the ball-to-material ratio is 4:1, then add 500ml of absolute ethanol, and roll the ball mill for 24 hours to obtain the slurry; the slurry is evaporated to dryness in a rotary evaporator at 60°C, and then placed in a vacuum drying oven Vacuum dry for at least 24 hours, take it out, grind for 20 minutes, and pass through a 100-mesh sieve to obtain the undersize; put the undersize into a graphite mold with a diameter of 20 mm, 2 Under the condition of gas protection and sintering pressure of 20Mpa, the heating rate was raised to 1000°C at a rate of 100°C / min, kept for 1min, and then raised to 1600°C at a rate of 100°C / min, sintered for 5m...

Embodiment 3

[0037] α-Si 3 N 4 , AlN, α-Al 2 o 3 , Li 2 CO 3 as raw material, according to Li m Si 12-m-n Al m+n o n N 16-n The stoichiometric ratio of (m=0.5, n=0.9) selects α-Si with a total weight of 100g 3 N 4 , AlN, α-Al 2 o 3 , Li 2 CO 3 Raw material, put into plastic bottle and mix, take Si 3 N 4 The ball is the ball milling medium, the ball-to-material ratio is 4:1, then add 500ml of absolute ethanol, and roll the ball mill for 24 hours to obtain the slurry; the slurry is evaporated to dryness in a rotary evaporator at 50°C, and then put into a vacuum drying oven to vacuum Dry for at least 24 hours, take it out, grind for 20 minutes, and pass through a 100-mesh sieve to get the undersize, put the undersize into a graphite mold with a diameter of 20mm, and then put it into a spark plasma sintering furnace. 2 Under the conditions of gas protection and sintering pressure of 20Mpa, the temperature was raised to 950°C at a rate of 100°C / min, kept for 1min, then raised t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com