Method for manufacturing three-dimensional large-size aluminum-lithium alloy round ingot through spray forming

An aluminum-lithium alloy, spray forming technology, applied in the field of aluminum-lithium alloy, can solve the problems of long process, difficult aluminum-lithium alloy billet, difficult densification, etc., achieve dense forming, good process stability, and avoid segregation of alloy elements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

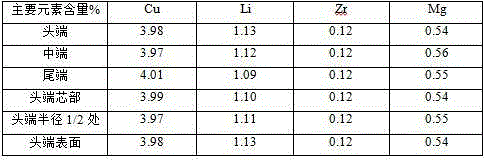

Embodiment 1

[0028] Embodiment 1: the production of 2195 aluminum-lithium alloy billets;

[0029] 1) Alloy weight percentage: Cu4.0%, Ag0.4%, Li1.2%, Zr0.12%, Mg0.56%, Fe<0.15%, Si<0.12%, Ti<0.1%, Zn<0.25, Al balance.

[0030] 2) Melt the weighed aluminum-lithium alloy components in a melting furnace, use a mixture of LiCl and KCl at a mass ratio of 1:1 as a covering agent, and the melting temperature is 740°C.

[0031] 3) After all the alloys are melted, pour Ar30min into the melt depth 2 / 3 for refining.

[0032] 4) After refining, let stand for 30 minutes, and then filter.

[0033] 5) Spray the filtered above melt.

[0034] The spray deposition process parameters are: spray angle 15°, atomization pressure 0.6MPa, atomization temperature 760°C, receiving pan rotation speed 40rpm, receiving pan descending speed 3.0mm / s, receiving distance 490mm, deposition chamber Ar pressure 1.05 Atmospheric pressure, the final deposition rate is 16kg / min, and the aluminum-lithium alloy ingot with a s...

Embodiment 2

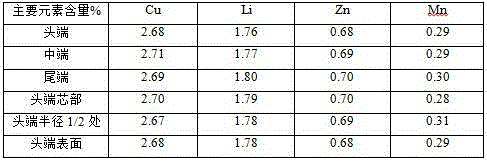

[0037] Embodiment 2: the production of 2099 aluminum-lithium alloy billets;

[0038]1) Alloy weight percentage: Cu2.7%, Ag0.4%, Li1.8%, Zr0.08%, Mg0.30%, Zn0.7%, Mn0.3%, Fe<0.07%, Si<0.05% , Ti<0.1%, Al balance.

[0039] 2) Melt the weighed aluminum-lithium alloy components in a melting furnace, use a mixture of LiCl and KCl at a mass ratio of 1:1 as a covering agent, and the melting temperature is 740°C.

[0040] 3) After all the alloys are melted, pour Ar35min into the 2 / 3 of the melt depth.

[0041] 4) After refining, let stand for 30 minutes, and then filter.

[0042] 5) Spray the filtered above melt.

[0043] The spray deposition process parameters are: spray angle 18°, atomization pressure 0.5MPa, atomization temperature 760°C, receiving pan rotation speed 40rpm, receiving pan descending speed 3.2mm / s, receiving distance 485mm, deposition chamber Ar pressure 1.1 Atmospheric pressure, the final deposition rate is 15kg / min, and the aluminum-lithium alloy ingot with a s...

Embodiment 3

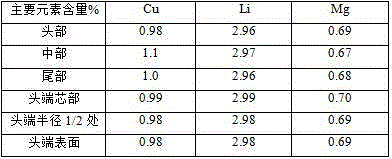

[0046] Embodiment 3: the production of VL30 aluminum-lithium alloy billet;

[0047] 1) Alloy weight percentage: Li3.0%, Cu1.0%, Mg0.7%, Fe<0.07%, Si<0.05%, Al balance.

[0048] 2) Melt the weighed aluminum-lithium alloy components in a melting furnace, use a mixture of LiCl and KCl at a mass ratio of 1:1 as a covering agent, and the melting temperature is 710°C.

[0049] 3) After all the alloys are melted, pass Ar40min to the 2 / 3 of the melt depth.

[0050] 4) After refining, let stand for 30 minutes, and then filter.

[0051] 5) Spray the filtered above melt.

[0052] The spray deposition process parameters are: spray angle 25°, atomization pressure 0.4MPa, atomization temperature 730°C, receiving pan rotation speed 40rpm, receiving pan descending speed 3.5mm / s, receiving distance 450mm, deposition chamber Ar pressure 1.1 Atmospheric pressure, the final deposition rate is 12kg / min, and the aluminum-lithium alloy ingot with a specification of Φ300×1000mm is obtained; the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com