Spray forming device for ultrahard aluminum lithium alloy

A spray forming and lithium alloy technology is applied in the field of spray forming devices for super-hard aluminum-lithium alloys, which can solve the problems of easy oxidation of the powder surface, impurities, and difficulty in densification, and achieve high ingot yield, good process stability, The effect of high forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

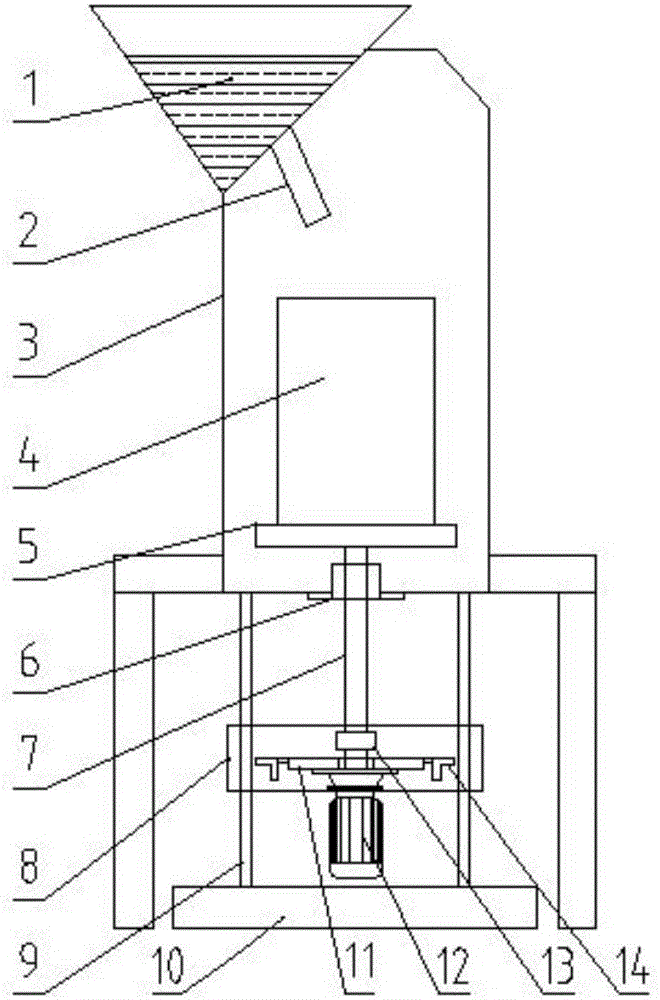

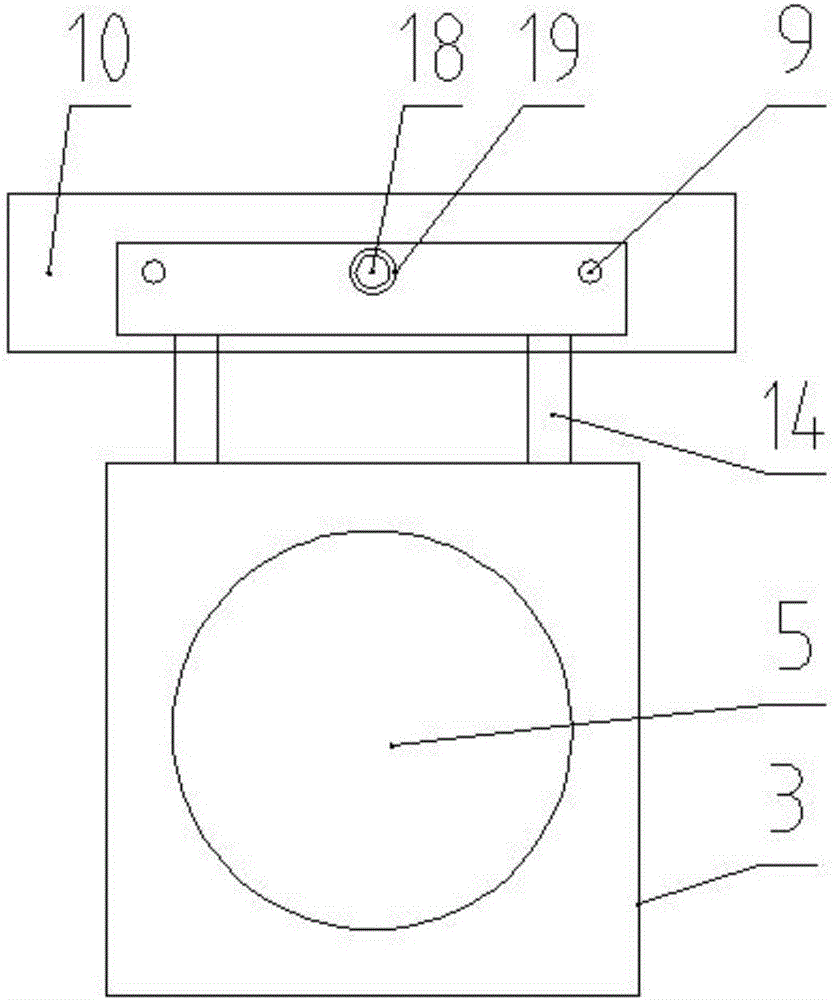

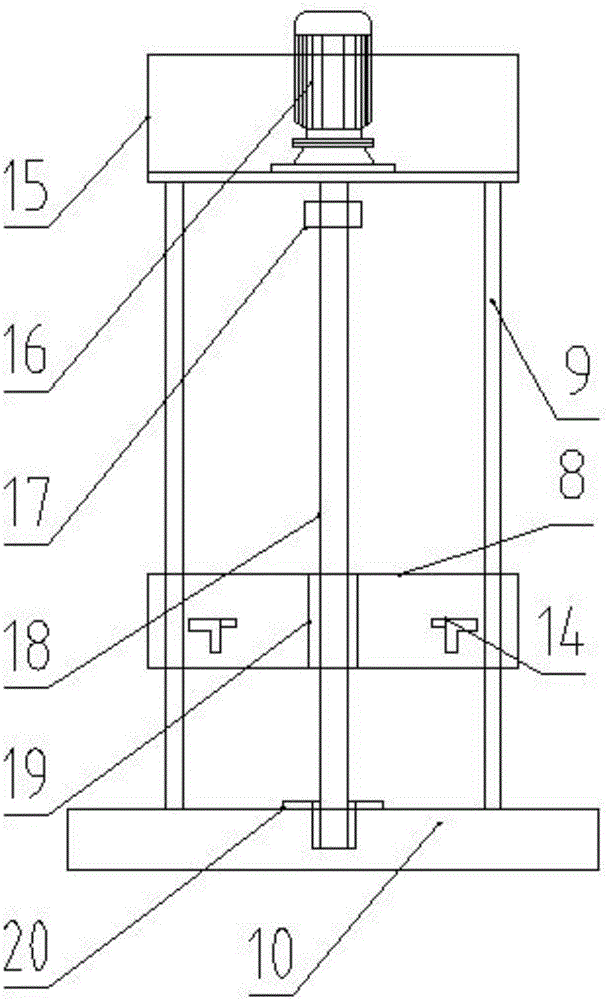

[0024] see figure 1 , figure 2 , image 3 , a spray forming device for superhard aluminum-lithium alloy, comprising: a rotating mechanism, a lifting mechanism, and a receiving tray 5, characterized in that: the lifting mechanism includes a screw rod 18, a screw rod sleeve 19, a guide rod 9, and a lifting bracket 8 , the screw sleeve 19 is fixed in the middle of the lifting bracket 8, the external thread of the inner threaded screw rod 18 in the screw sleeve 19 is threaded, and the two sides of the lifting bracket 8 are provided with two groups of guide rod holes in the vertical direction. Two groups of guide rods 9 pass through the guide rod holes, two groups of guide rods 9 are fixed between the lifting motor fixing base 15 and the chassis 10, and one end of the screw rod 18 is connected with the main shaft of the lifting motor 16 through the screw coupling 17 , the rotating mechanism includes a rotating shaft 7, a rotating motor 12, a rotating motor fixing seat 11, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com