A forming device and method using a wire to guide molten metal coating

A technology of molten metal and metal wire, which is applied in the field of forming devices that use metal wires to guide molten metal coating, and metal coating forming devices. It can solve the problems that affect the accuracy of cladding and forming parts, and it is difficult to control, so as to improve mass production. Possibility, small heat-affected zone, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

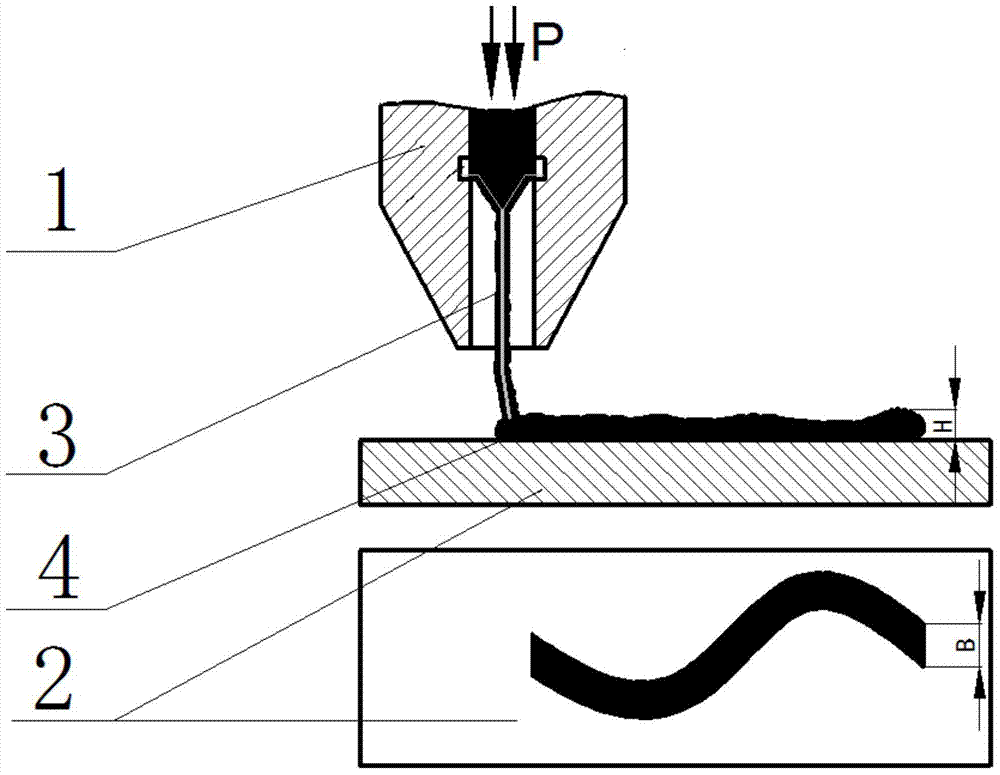

[0018] refer to figure 1 , the molding device of the present invention that utilizes a metal wire to guide molten metal coating includes a substrate 2, a nozzle 1, a 3D displacement platform and a metal wire 3, the substrate 2 is fixed on the 3D displacement platform, and the upper end of the metal wire 3 is inserted into the nozzle 1 in the nozzle at the bottom, and the upper end of the metal wire 3 is fixed on the inner surface of the nozzle, the lower end of the metal wire 3 is suspended, and the angle between the lower end of the metal wire 3 and the substrate 2 is 90-95°, the nozzle 1 and the metal wire 3 are located above the substrate 2; the metal wire 3 is a tungsten wire.

[0019] The molding method utilizing wire guide molten metal coating of the present invention comprises the following steps

[0020] 1) First, the molten metal is delivered to the nozzle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com