A water cooling device system and its control method for the production of plastic pencils

A water-cooling device and pencil technology, applied in the field of water cooling, can solve the problems of unfavorable development and low production efficiency, and achieve the effects of reducing manual learning costs, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

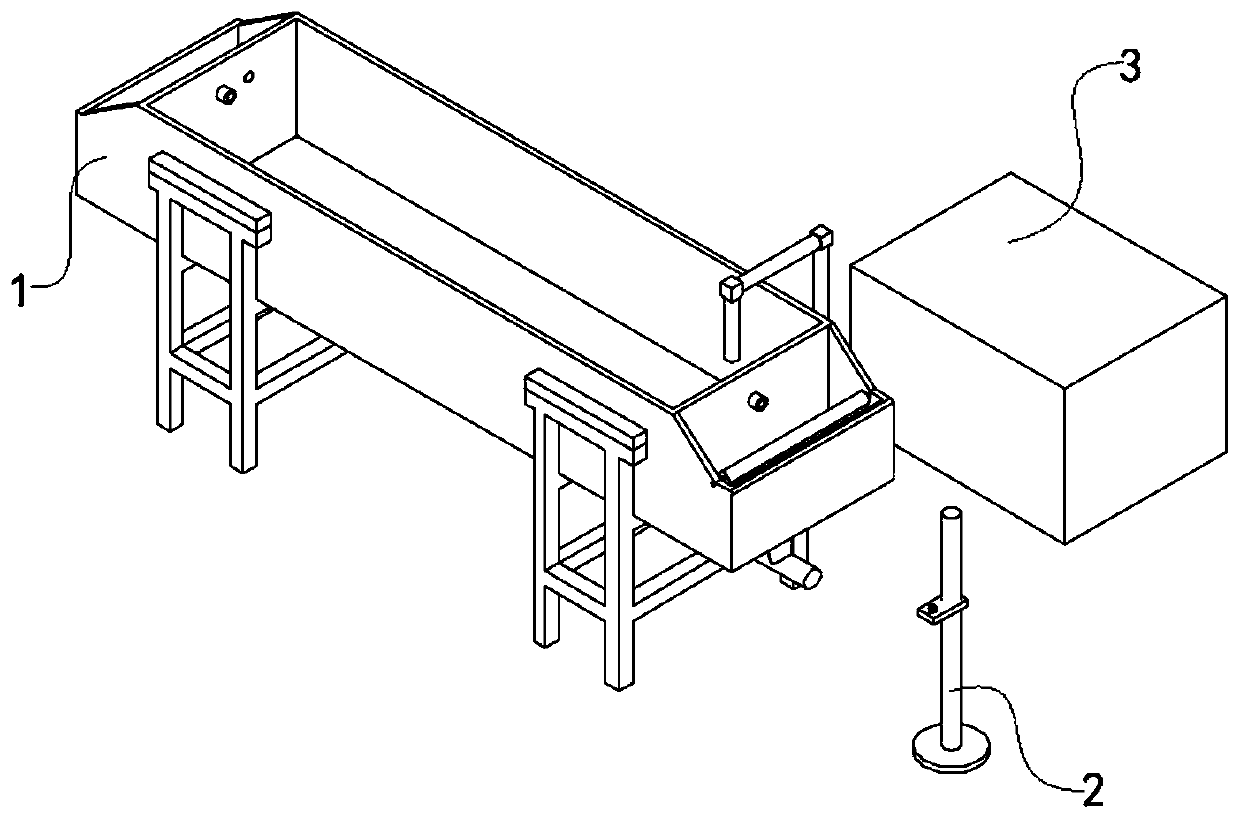

[0037] see figure 1 As shown, the present invention is a kind of water cooling device system for the production of plastic pencils, comprising a cooling tank 1, a monitoring device 2 and a water circulation device 3, characterized in that: the front station of the cooling tank 1 is provided with a monitoring device 2; The side of the tank 1 is provided with a water circulation device 3; the monitoring device 2 includes a photoelectric sensor.

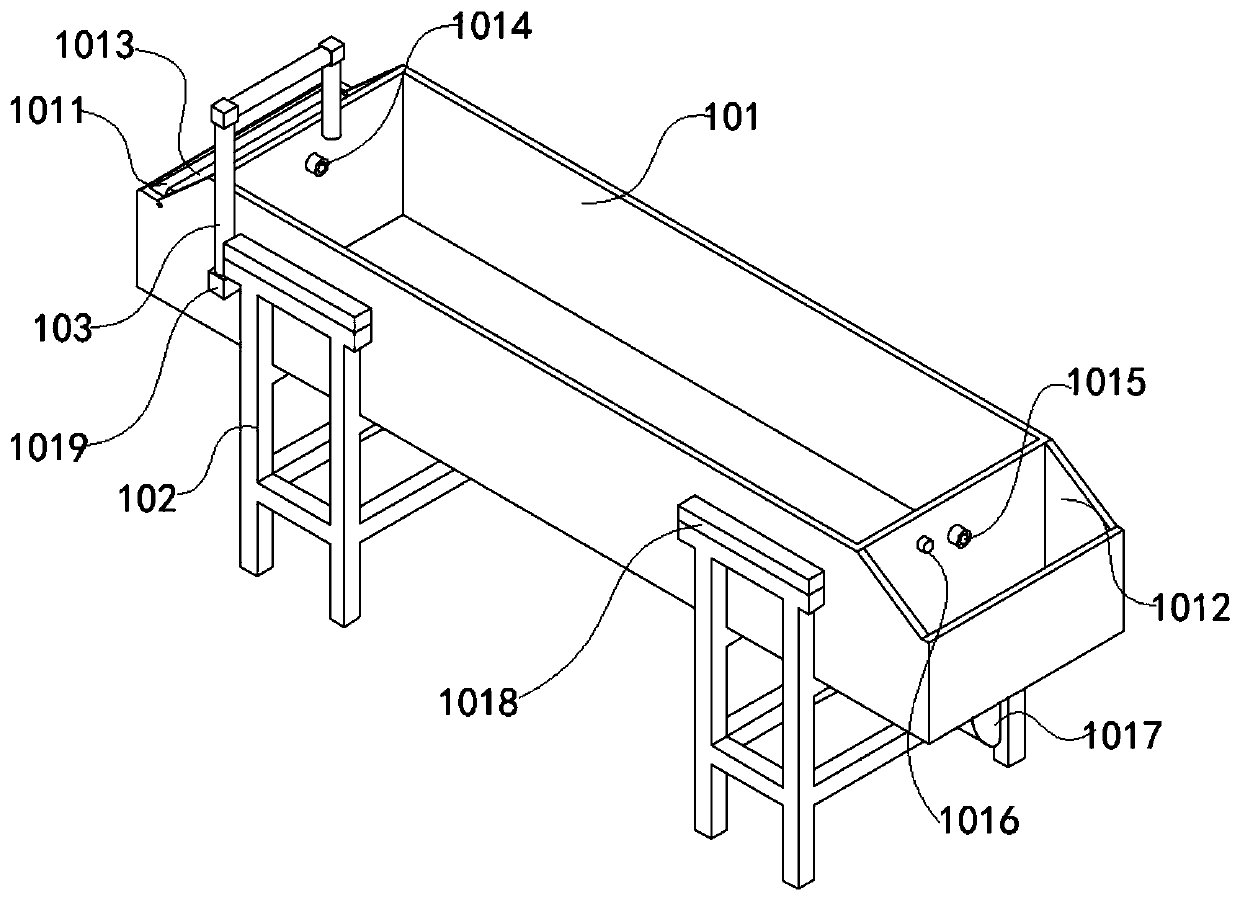

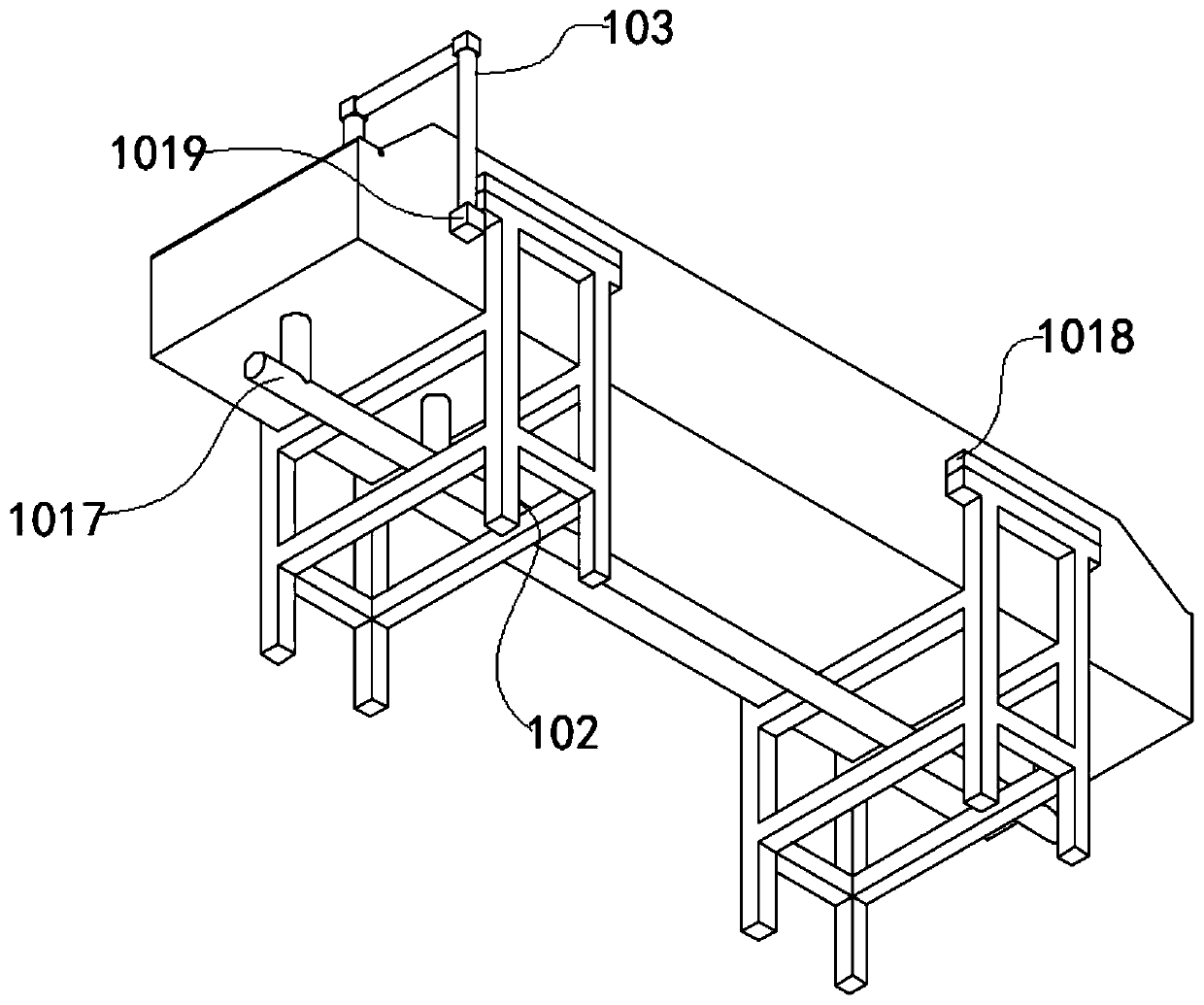

[0038] Such as Figure 2-5 As shown, the cooling tank 1 includes a water cooling tank body 101, a bracket 102 and a water pipe bracket 103; the water cooling tank body 101 is placed on the bracket 102; the water cooling tank 101 side is equipped with a water pipe bracket 103; When stop using, the water in the water-cooling tank body 101 is discharged to prolong the service life of the equipment; the side of the water-cooling tank body 101 is provided with some matching support seats 1018; the surface of the support seat 1018 is connect...

Embodiment 2

[0045] see Figure 8 As shown, a control method for a water cooling device used in the production of plastic pencils, including

[0046] The following steps:

[0047] SS01: The photoelectric sensor monitors the signal on and off, and outputs the photoelectric on and off signal to the MCU control chip;

[0048] SS02: The MCU control chip judges whether the pencil is broken according to the on-off signal of the photoelectric sensor. When the signal of the photoelectric sensor is blocked, the pencil is in a continuous state, and SS03 is executed; otherwise, it is in a broken state, and SS04 is executed;

[0049] SS03: Start the water pump and inject cold water into the cooling tank 1;

[0050] SS04: Stop the water pump and start the siren alarm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com