Copper and copper alloy surface conditioning agent

A surface treatment agent, copper alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of weak alkalinity, unfavorable appearance of printed circuit boards, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

[0024] The present invention can be used as a prepreg when applied to the organic solder protection film process for printed circuit boards. The aqueous solution of the prepreg contains 0.85% xanthine by weight, 5.1% by weight of sodium carbonate, and 0.8% by weight of Sodium hydroxide, ammonium bromide with a weight ratio of 0.038%, the pH value is adjusted to 11, and the temperature is set at 25°C.

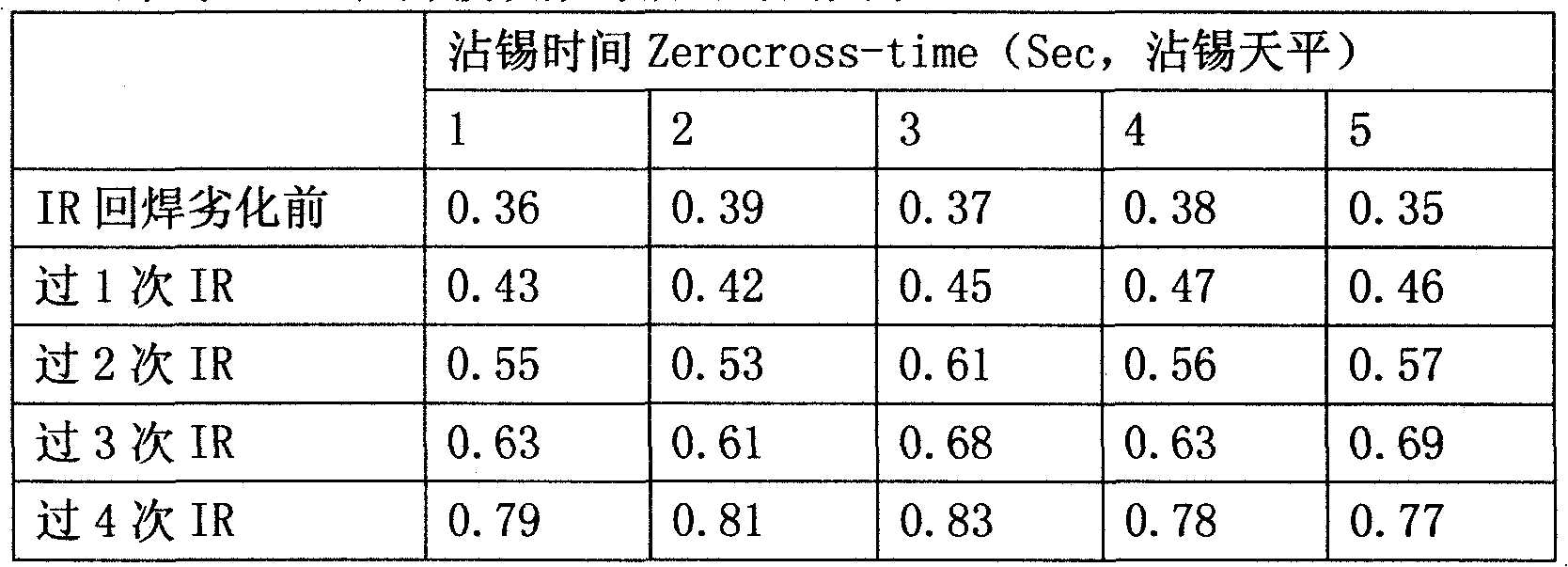

[0025] In the process of organic solder protection coating film for printed circuit boards, acidic or alkaline cleaners are used to remove oil stains on the surface of printed circuit boards, and after washing with water, the surface of copper or copper alloys is roughened with sulfuric acid / hydrogen peroxide microetching solution to improve organic Adhesion of solder protection film on copper or copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com