Laser additive heterogeneous alloy repairing method for small-thickness defects on surface of injection mold steel

A laser additive and injection mold technology, applied in the direction of additive processing, additive manufacturing, etc., can solve the problems of complex forming process, large differences in composition and structure, easy cracking, etc., and achieve the effect of good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

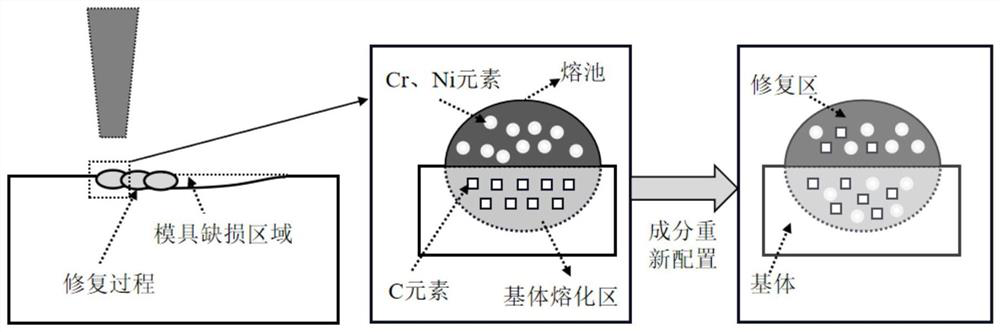

[0021] figure 1 For the schematic diagram of the laser additive hetero alloy repair on the surface of the die steel, the main constituent elements of the matrix and the repair material are redistributed in the molten pool, so as to achieve the ability to achieve high hardness repair.

[0022] The process parameters of laser deposition and forming: the laser power is 2000W, the scanning rate is 6mm / s, the powder feeding rate is 8g / min, the forming process is carried out in an argon atmosphere protection environment (oxygen content <200ppm), and the amount of defocusing during the deposition process The diameter of the light spot is 40mm, the diameter of the spot size is 3mm, the flow rate of the carrier gas is 15L / min, and the surface of the substrate is polished with 240# sandpaper before forming. The repair process adopts a lap rate of 40 to 60%.

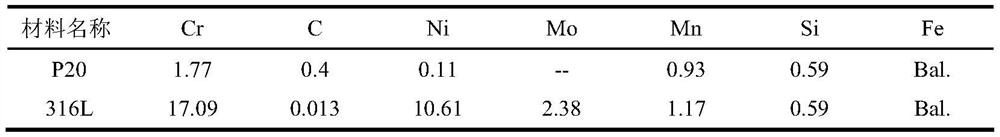

[0023] The 316L stainless steel powder is used as the repair material, and the hardened P20 mold is used as the mold base. Its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Matrix hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com