Quick carbon deposition method of carbon/carbon material member

A technology of carbon materials and components, which is applied in the field of rapid prototyping of carbon/carbon materials, can solve problems such as the need to punch holes in products, and achieve the effects of low porosity, avoiding adhesion, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Using PAN-based 12k carbon fiber to prepare a carbon fiber prefabricated body with a needle-punched structure without weft cloth and mesh tire. The carbon fiber prefabricated body is a hollow cylinder with a size of Φ600mm (outer diameter)×Φ540mm (inner diameter)×800mm (height), The initial density is 0.45g / cm 3 .

[0026] (2) Put the carbon fiber preform into a high-temperature graphitization furnace for high-temperature pretreatment. The high-temperature pretreatment temperature is 2000°C, and the holding time is 3h. After high-temperature pretreatment, its bulk density is 0.425g / cm 3 .

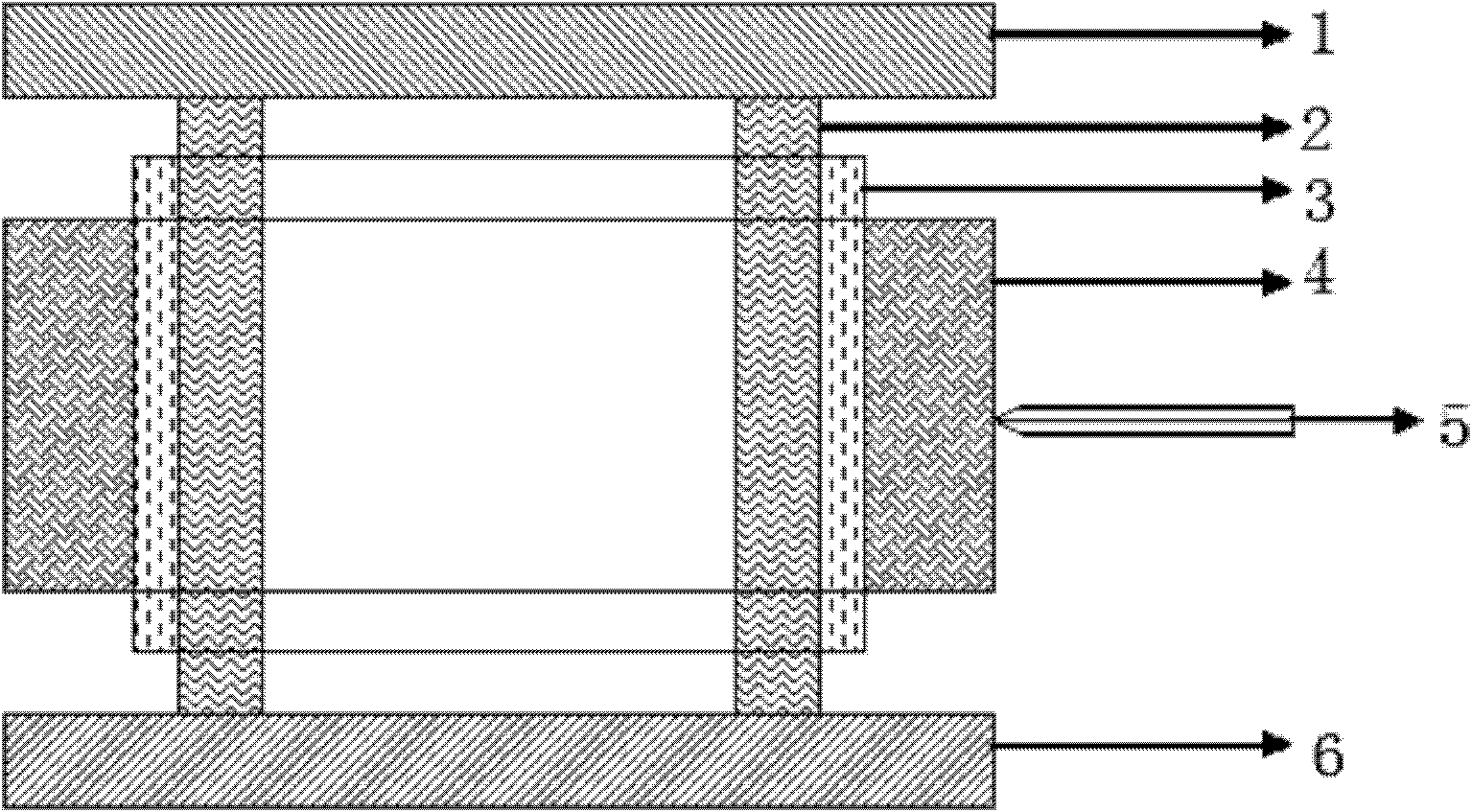

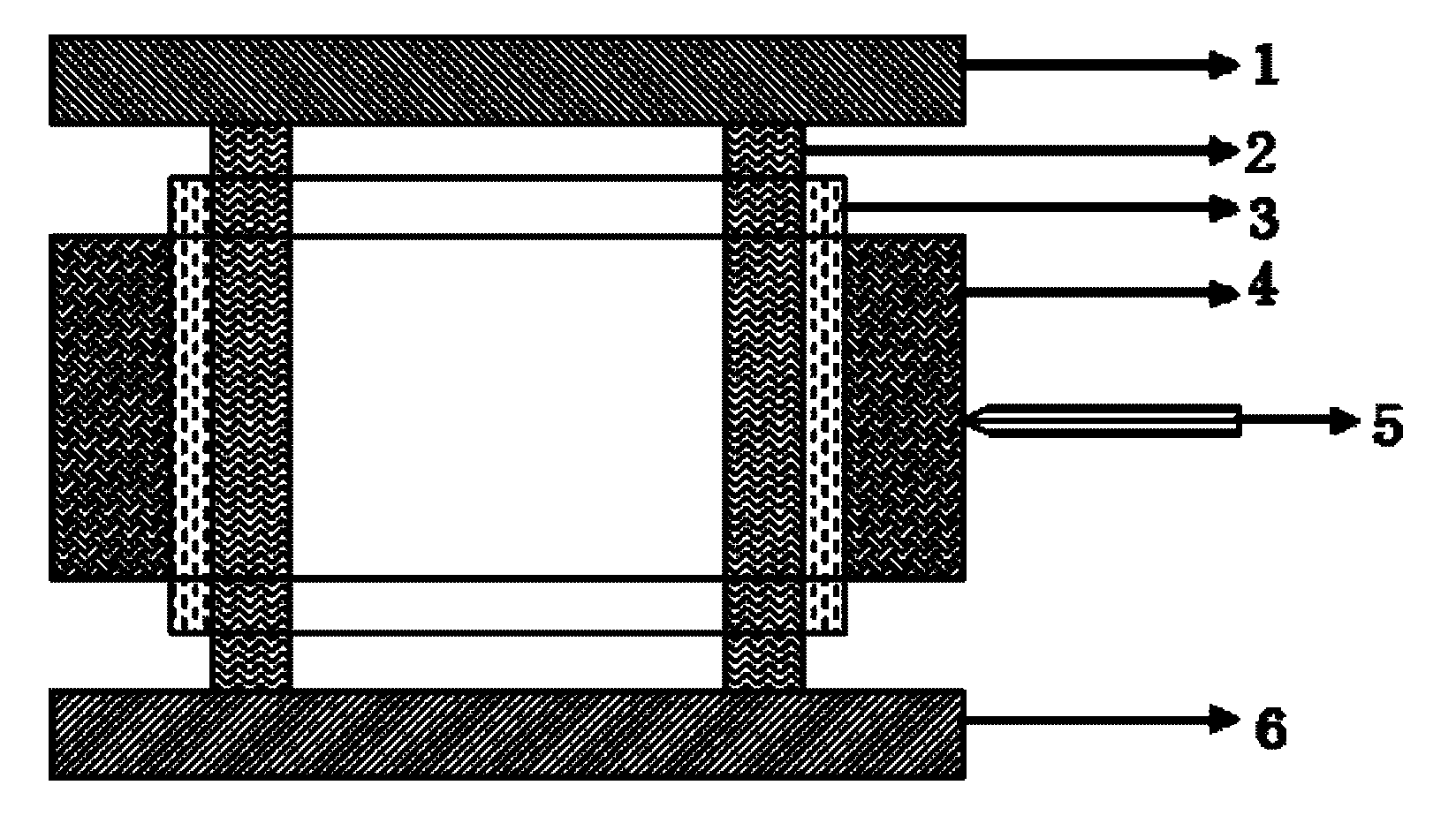

[0027] (3) if figure 1 As shown, the carbon fiber preform 4 that has been pretreated at high temperature in step (2) is bound to the heating element 2 with 6k carbon fibers, and the carbon fiber preform 4 and the heating element 2 are separated 3 by two layers of kraft paper. The heating element is made of graphite material, and the size is Φ540mm (outer diameter)×Φ500mm (inne...

Embodiment 2

[0031] (1) Use PAN-based 6k carbon fiber to prepare a carbon fiber prefabricated body with a needle-punched structure without weft cloth and mesh tire. The carbon fiber prefabricated body is a hollow cylinder with a size of Φ650mm (outer diameter)×Φ540mm (inner diameter)×400mm (height) , the initial density is 0.46g / cm 3 .

[0032] (2) Put the carbon fiber prefabricated body into a high-temperature graphitization furnace for high-temperature pretreatment. The high-temperature pretreatment temperature is 2200°C, and the temperature is kept for 1 hour. After high-temperature pretreatment, its bulk density is 0.432g / cm 3 .

[0033] (3) if figure 1 As shown, the carbon fiber preform that has been pretreated at high temperature in step (2) is bound to the heating element 2 with 12k carbon fibers, and the carbon fiber preform 4 and the heating element 2 are separated by flexible graphite paper 3 with a thickness of 0.5 mm. The heating element is made of graphite material, and its...

Embodiment 3

[0037] (1) Use PAN-based 6k carbon fiber to prepare a plain-weave carbon cloth laminated structure. The carbon fiber preform is flat, with a size of 800mm×800mm×50mm and an initial density of 0.65g / cm 3 .

[0038] (2) Put the carbon fiber prefabricated body into a high-temperature graphitization furnace for high-temperature pretreatment. The high-temperature pretreatment temperature is 2000°C, and it is kept for 2 hours. After high-temperature pretreatment, its bulk density is 0.63g / cm 3 .

[0039](3) Bonding 0.5 mm thick flexible graphite paper to the heating element with phenolic resin, and then bonding the carbon fiber preform that has been pretreated at high temperature in step (2) to the flexible graphite paper with phenolic resin. The heating element is made of graphite material, and the size is 900mm×900mm×20mm. An upper electrode 1 and a lower electrode 6 are respectively installed on the upper and lower sides of the heating element 2 . The upper electrode and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com