Thermoelectric material Mg2Sn and preparation method thereof

A technology of thermoelectric materials and bulk materials, applied in the field of thermoelectric materials Mg2Sn and its preparation, can solve problems such as easy oxidation, easy volatilization, and harsh temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

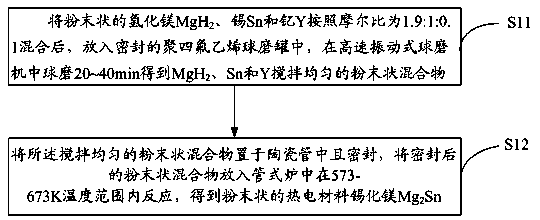

[0014] The present invention adopts MgH 2 Synthesis of thermoelectric material Mg by reaction method 2 Sn powder, combined with electric field activated pressure-assisted synthesis of FAPAS to achieve Mg 2 Rapid densification of Sn-based bulk materials for thermoelectric materials Mg 2 Sn, the corresponding reaction formula is: MgH 2 +S n →Mg 2 S n +H 2 ↑The material preparation method specifically includes the following steps:

[0015] Step 1: powdered magnesium hydride MgH 2 , tin Sn and yttrium Y are mixed according to the molar ratio of 1.9:1:0.1. Specifically, in an argon (Ar gas) protected glove box, the MgH 2 Powder, Sn powder, and Y powder are mixed according to the molar percentage of 1.9:1:0.1 to obtain a preliminary mixture;

[0016] MgH 2 And Sn as a reactive substance, Y as a dopant, doping Y can improve the electrical properties of thermoelectric materials;

[0017] Step 2: Stir the mixture so that the components are evenly mixed. Specifically, seal t...

Embodiment approach 2

[0024] see figure 1 , the Mg provided by the embodiment of the present invention 2 The preparation method of Sn, powdery magnesium hydride MgH 2 , tin Sn and yttrium Y were mixed according to the molar ratio of 1.9:1:0.1, put into a sealed polytetrafluoroethylene ball mill jar, and ball milled in a high-speed vibrating ball mill for 30 minutes (min) to obtain MgH 2 , Sn and Y are uniformly stirred powdery mixture; the uniformly stirred powdery mixture is placed in a ceramic tube and sealed, and the sealed powdery mixture is put into a tube furnace for reaction at 673K (400°C), Obtain the powdery thermoelectric material magnesium tin oxide Mg 2 Sn, others are the same as embodiment 1.

Embodiment approach 3

[0026] Mg 2 The graphite mold of Sn is placed in the FAPAS furnace activated by the electric field for sintering, and the bulk Mg with the shape corresponding to the graphite mold is obtained 2 Sn, the powdered Mg 2 The graphite mold of Sn is placed in a vacuum FAPAS furnace with a vacuum degree not greater than 15Pa, the current speed of the FAPAS furnace is set to 800-1000A, and the powdered Mg 2 Sn is heated to 800K to make it sintered, and others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com