Filtering equipment of air gap control

A technology of pore size and filter, which is applied in the direction of membrane filter, fixed filter element filter, filter separation, etc., and can solve the problems of inability to perform pressurized filtration, small filter area, and filter materials that cannot be tensioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

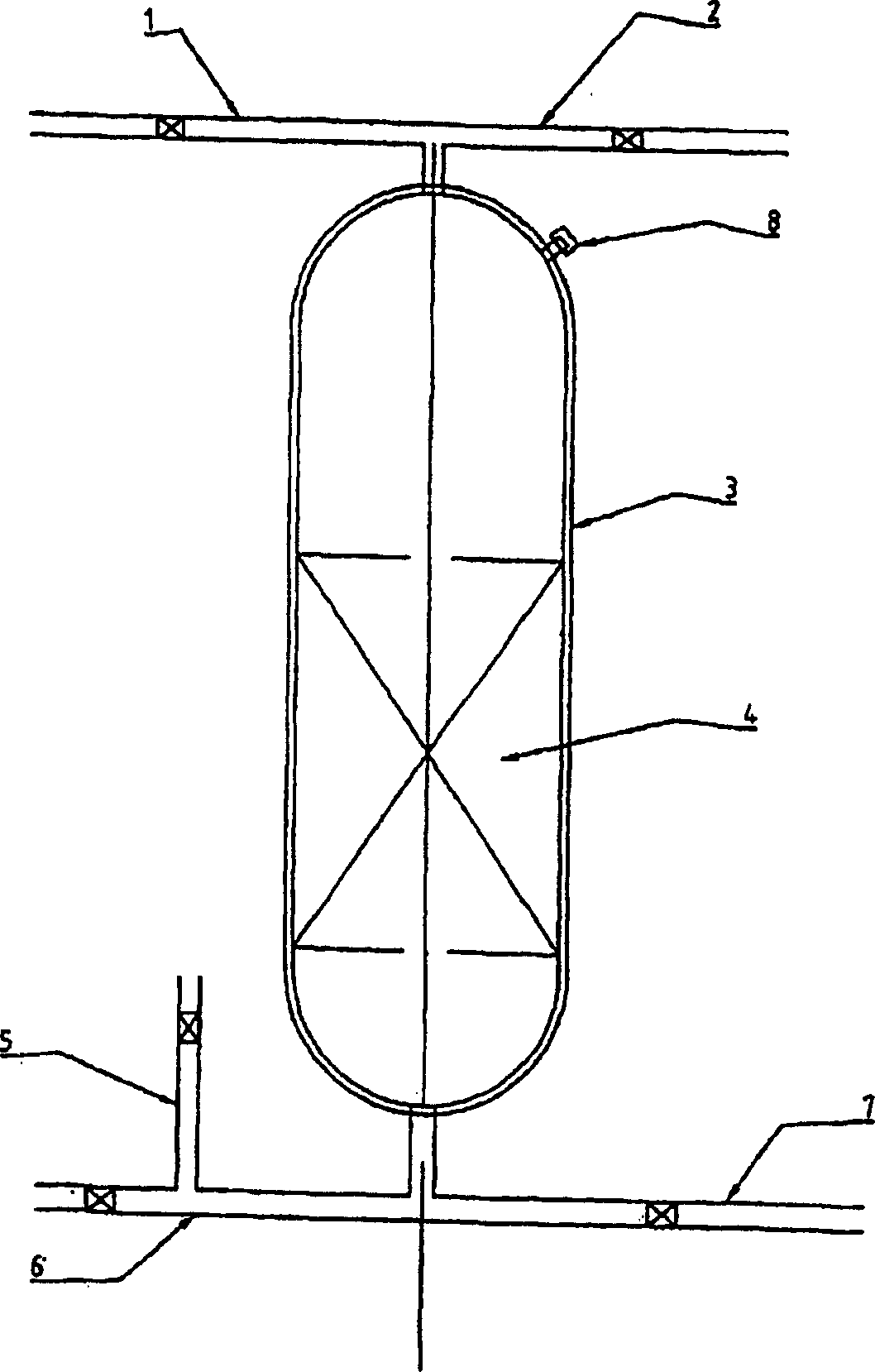

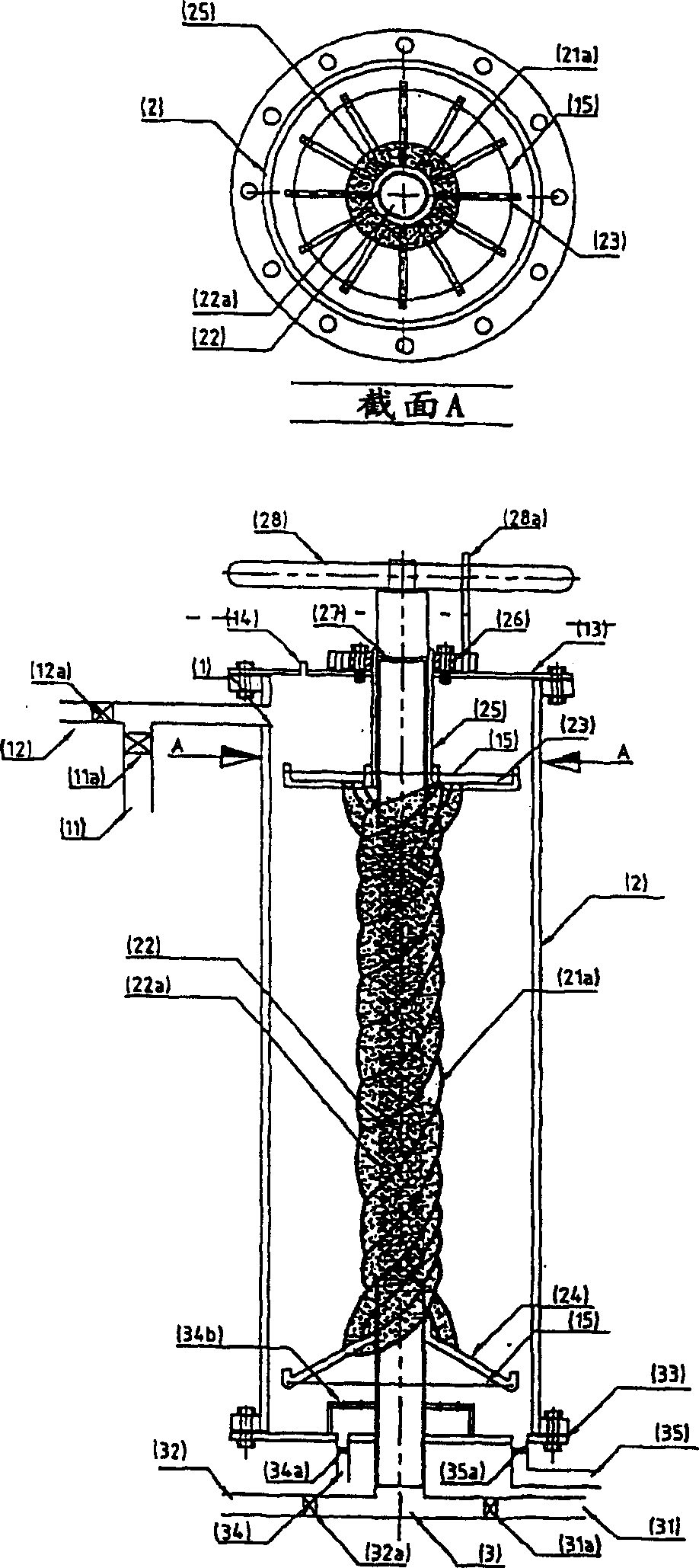

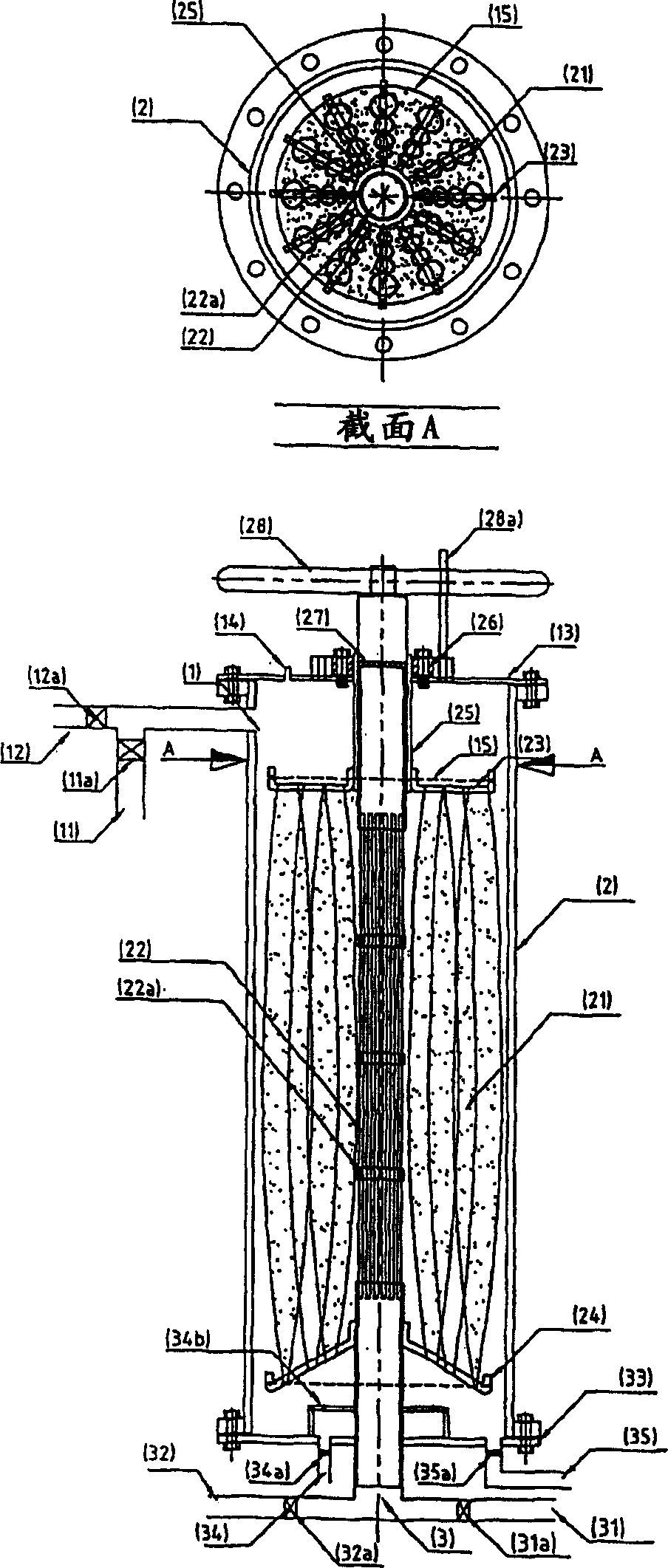

[0027] figure 2is a view of a one-stage rotary adjustable aperture filter 120 according to an embodiment of the present invention. As shown in the figure, a raw water delivery unit (1), a filter layer (21a), and a treated water discharge member (3) are installed from the circumferential direction to the central direction of the filter barrel (2). In the upper flange (13) of the filter bucket (2), a hole is formed into which the upper shaft (25) is inserted, and a hole engaged with the upper shaft sealing part (26) is formed so that water does not flow through the upper The gap between the shaft (25) and the upper flange (13), and a welded pipe, is used to engage the safety valve (14) and take pressure measurement. The perforated pipe (22) passes through the lower flange (33) of the filter tub (2) and is welded thereto, and a welded pipe is used to connect the washing air delivery pipe (34). One end of the upper rotating shaft (25) is connected with the upper handle (28), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com