Porous electrode and lithium secondary cell having same

A technology for lithium secondary batteries and porous electrodes, which is applied in the field of lithium secondary batteries with porous electrodes, can solve the problems of insufficient strength, weakened current collecting ability of the current collector, and easy damage during preparation or use, and achieves the pore size. Small, beneficial to lithium ion migration, and the effect of improving capacitance and current collection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

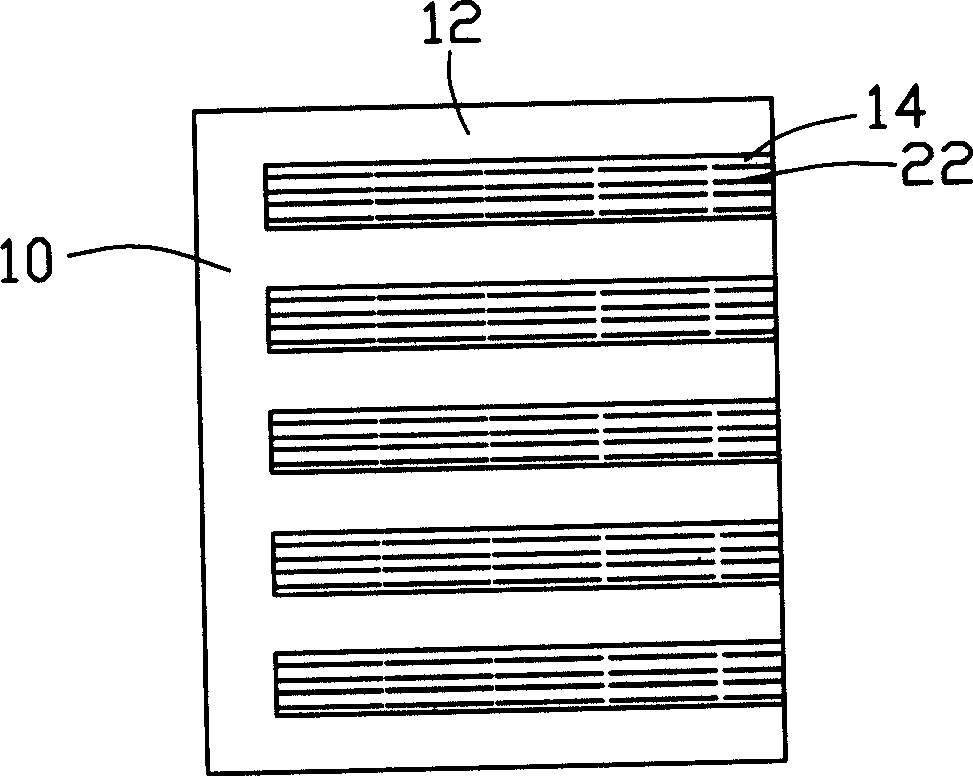

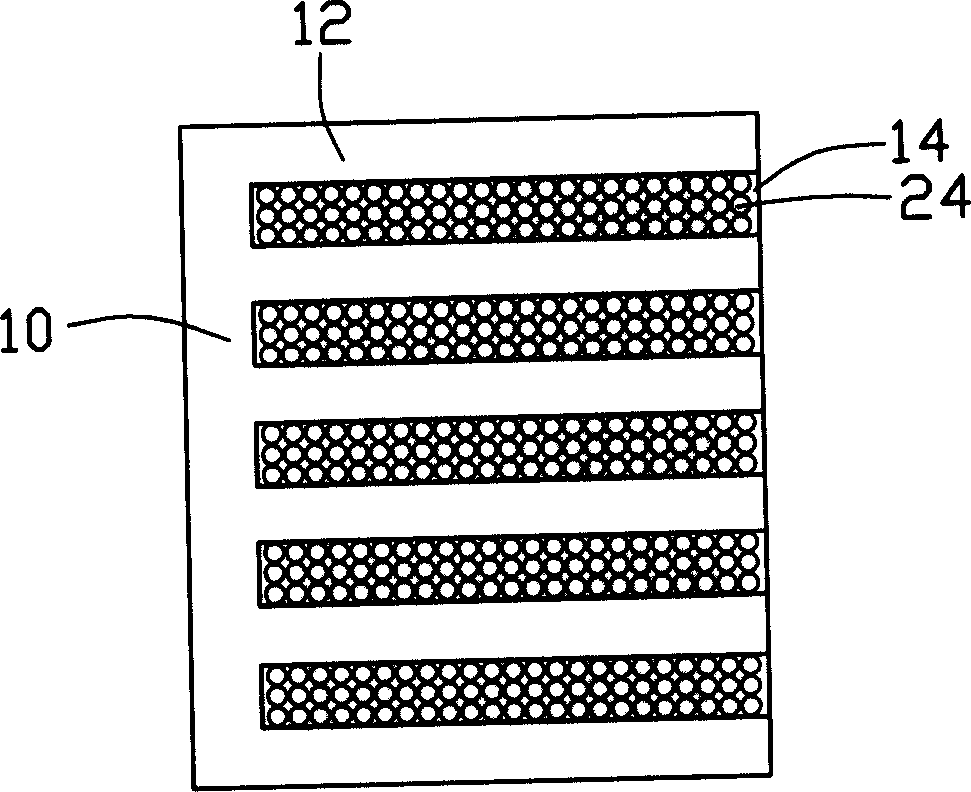

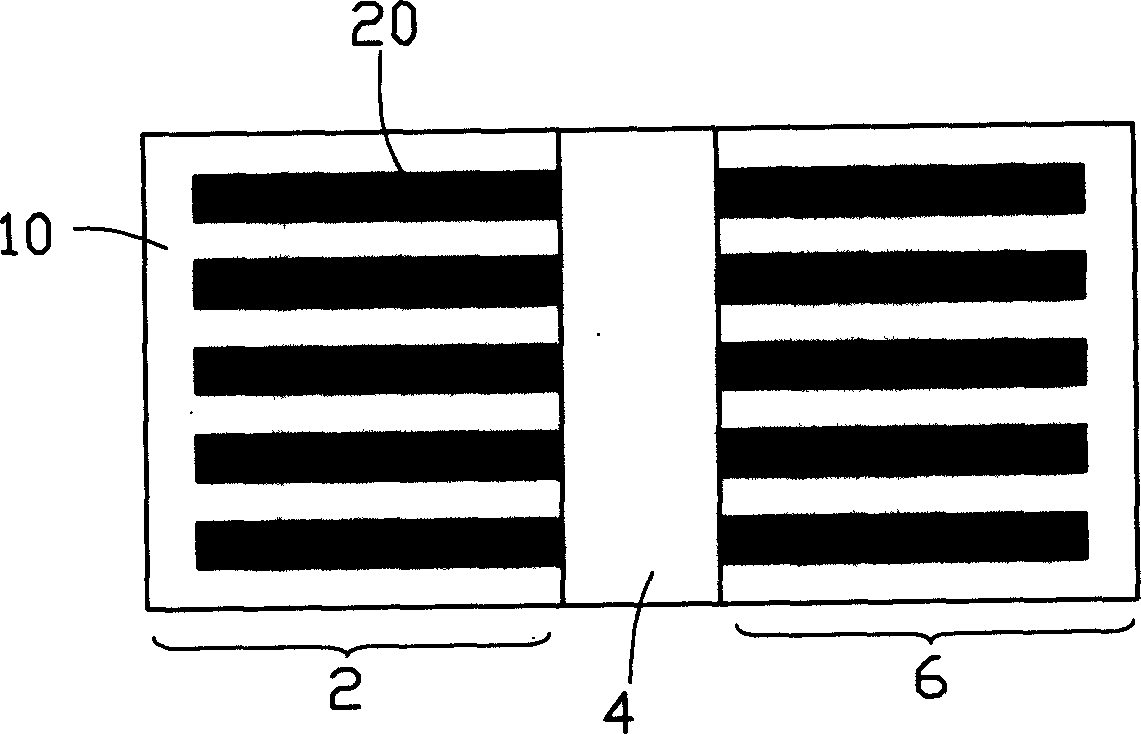

[0019] Such as figure 1 As shown, the first embodiment of the porous electrode structure of the present invention includes: a metal substrate 10, which can be used as a current collector, and has a bottom end (not shown), and a plurality of hole walls extending vertically outward from the bottom end 12, and a plurality of pores 14 formed between the pore walls 12, the pores 14 have a predetermined pore size, extend from the closed bottom end of the substrate 10 in the same direction, and the other end is an opening, between adjacent pores 14 Separated by hole walls 12; carbon nanotubes 22 are filled in the holes 14 as negative electrode active materials.

[0020] The cross-sectional shape of the pores 14 can be circular, elliptical, triangular or polygonal, and its shape and size can be determined according to the size of the filler and the preparation process. If the shape and size are too large, the available pores of the same volume of the substrate will The reduction in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com