High Rate Filtration System

a filtration system and high-rate technology, applied in water cleaning, water/sewage multi-stage treatment, separation processes, etc., can solve the problems of reducing the amount of room available for the media, complicating the operation of the device, and the difficulty of moving the bottom plate, so as to reduce the amount of media to be filtered, the effect of less media washing and low flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

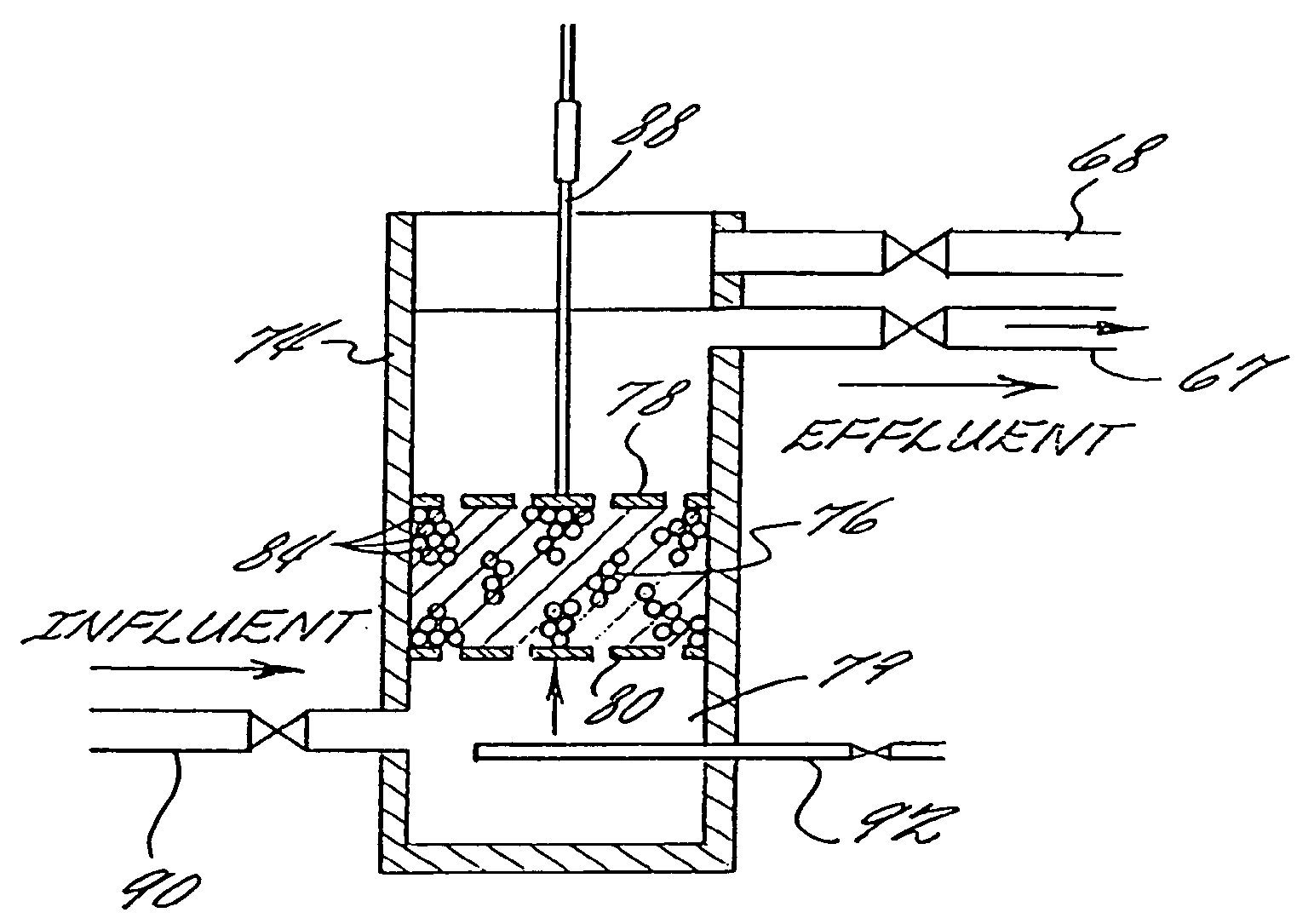

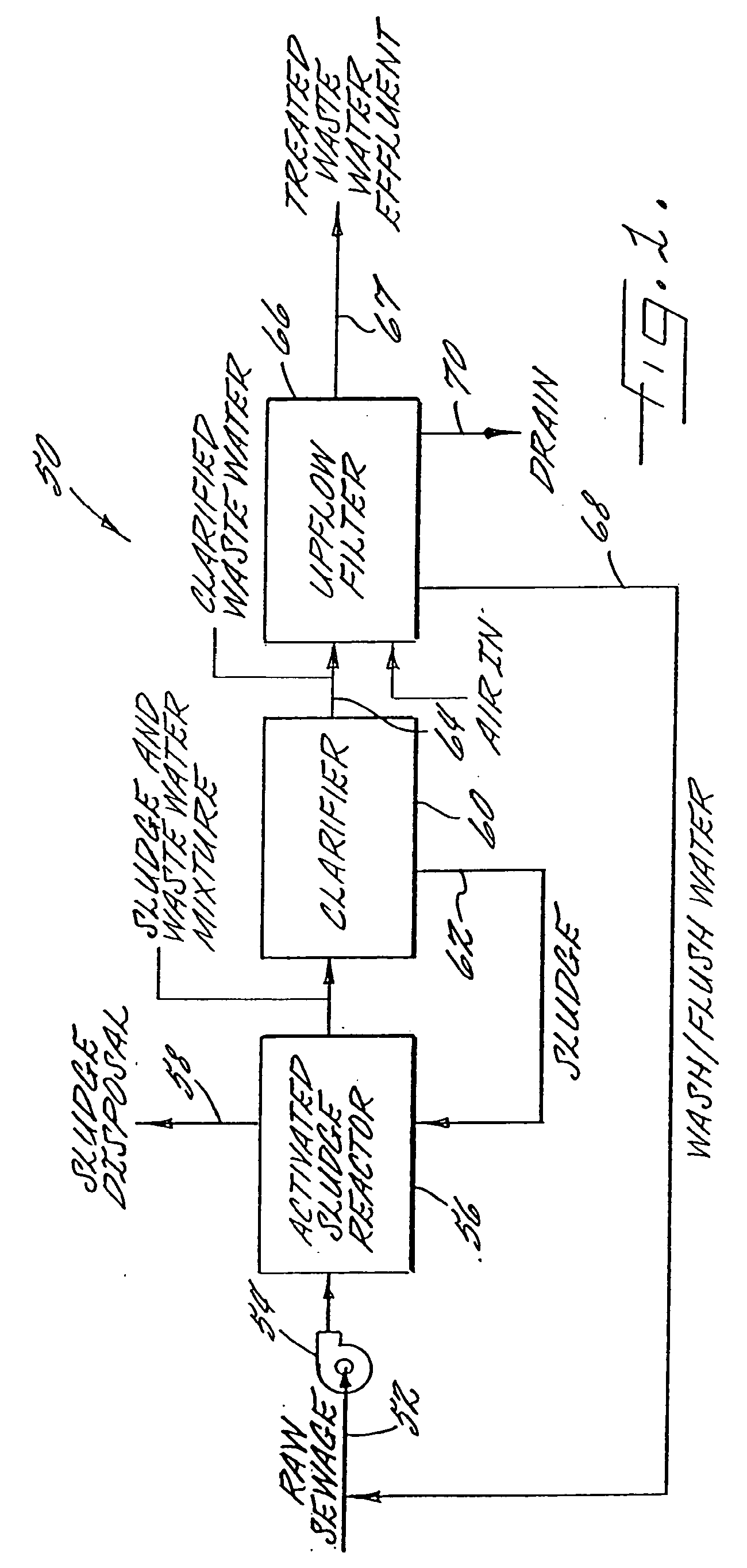

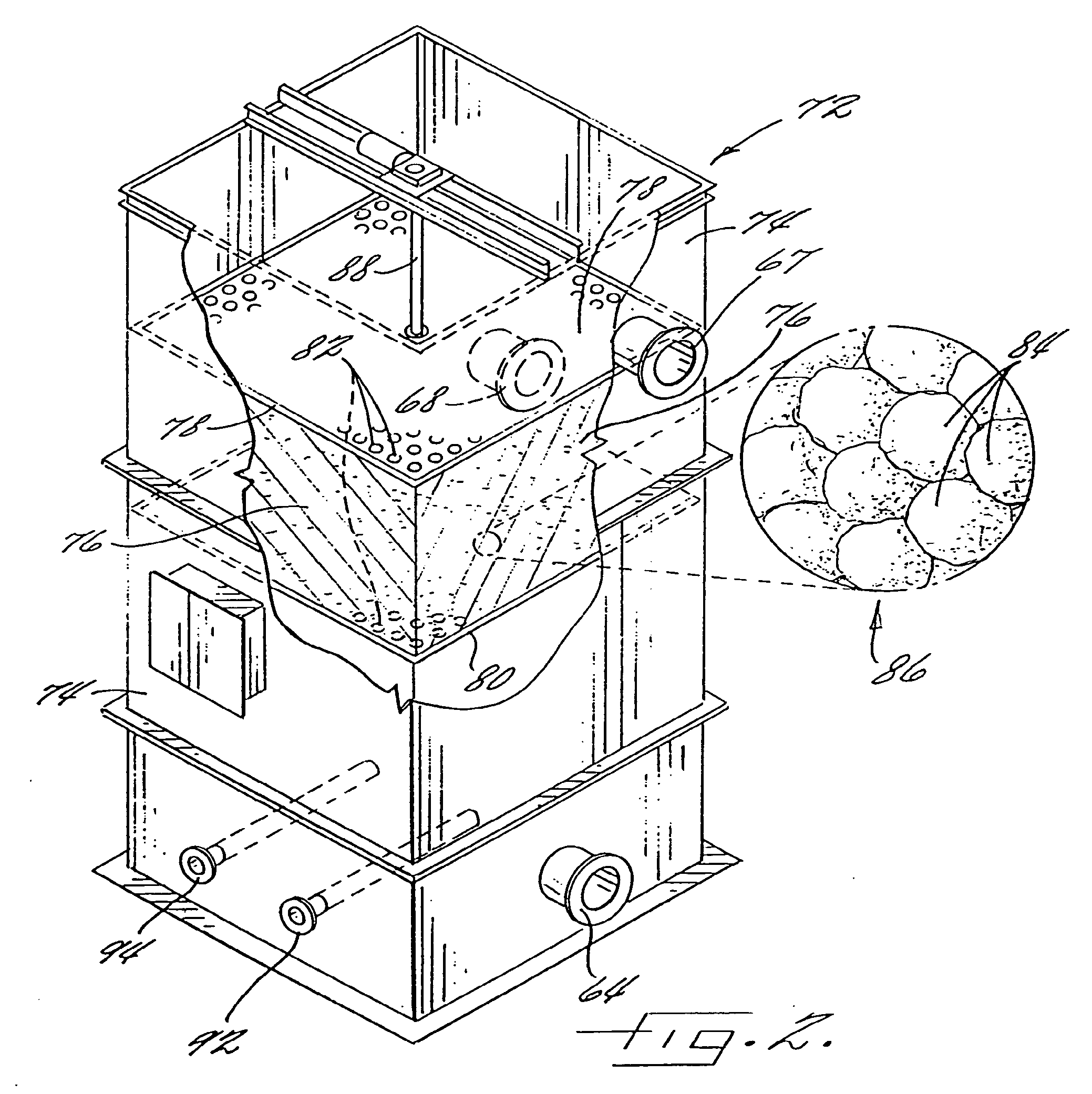

[0033]Represented in FIG. 1 generally at 50 in highly schematic form is a representative activated sludge plant incorporating the filtration apparatus of the invention for tertiary treatment of raw municipal sewage for increased removal of suspended solids. It should be recognized that the configuration of the activated sludge plant as represented is but one example of an activated sludge plant and that numerous alternatives are available. It should also be recognized that, while the invention is described in the context of a tertiary treatment system for municipal sewage that is treated by an activated sludge process, the invention described herein is not so limited.

[0034]The invention is not limited to particular configurations or modes of operation of activated sludge plants, or to use in connection with an activated sludge plant. For example, the filtration apparatus of the invention can be used to treat wastewater that is not subjected to sludge digestion. Where it is desired t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com