Flame-retardant coating composition

A technology of flame retardant coatings and compositions, applied in the direction of coatings, etc., can solve the problems of unsatisfactory fire resistance and physical and chemical properties, and achieve the effect of improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

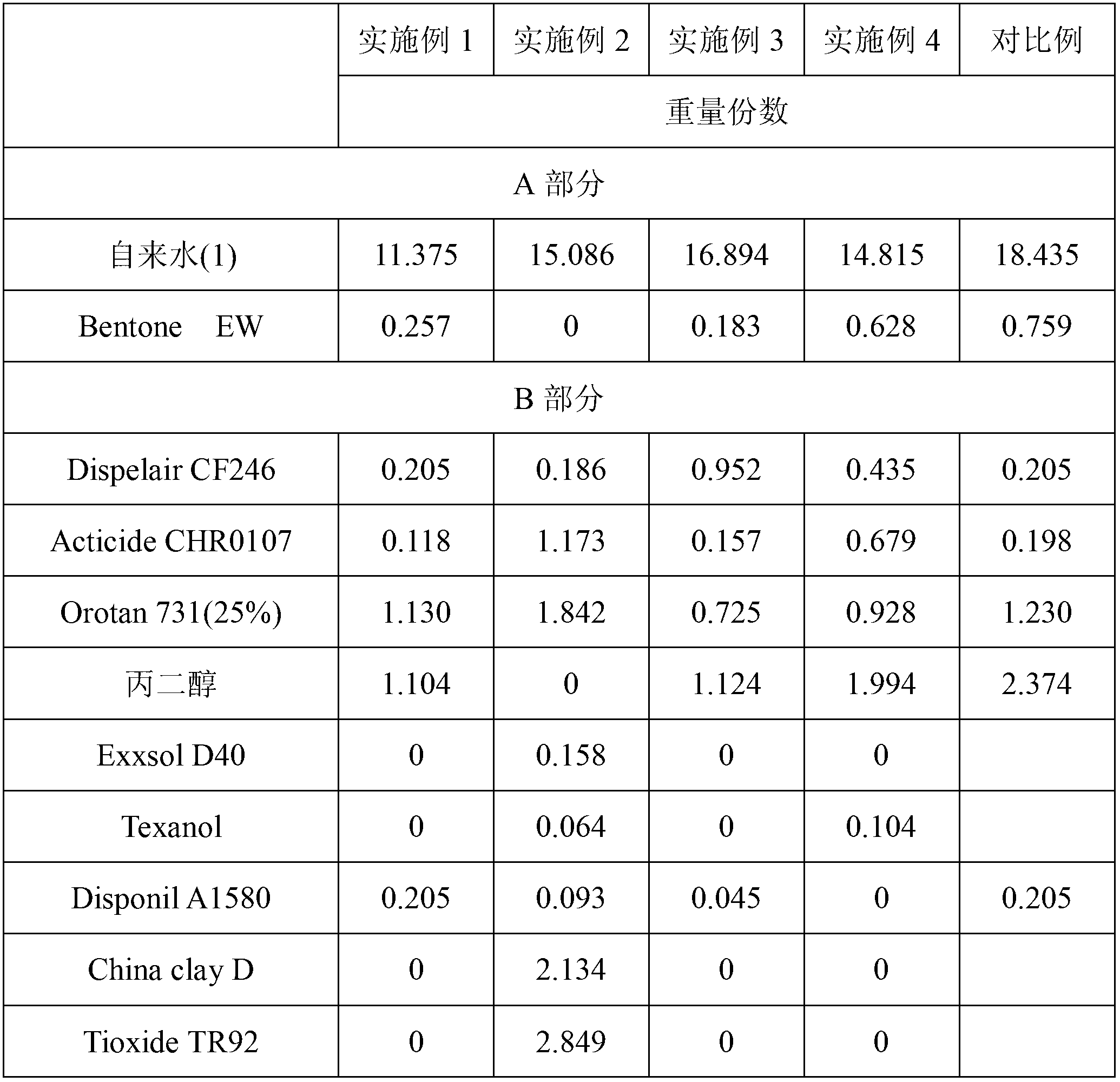

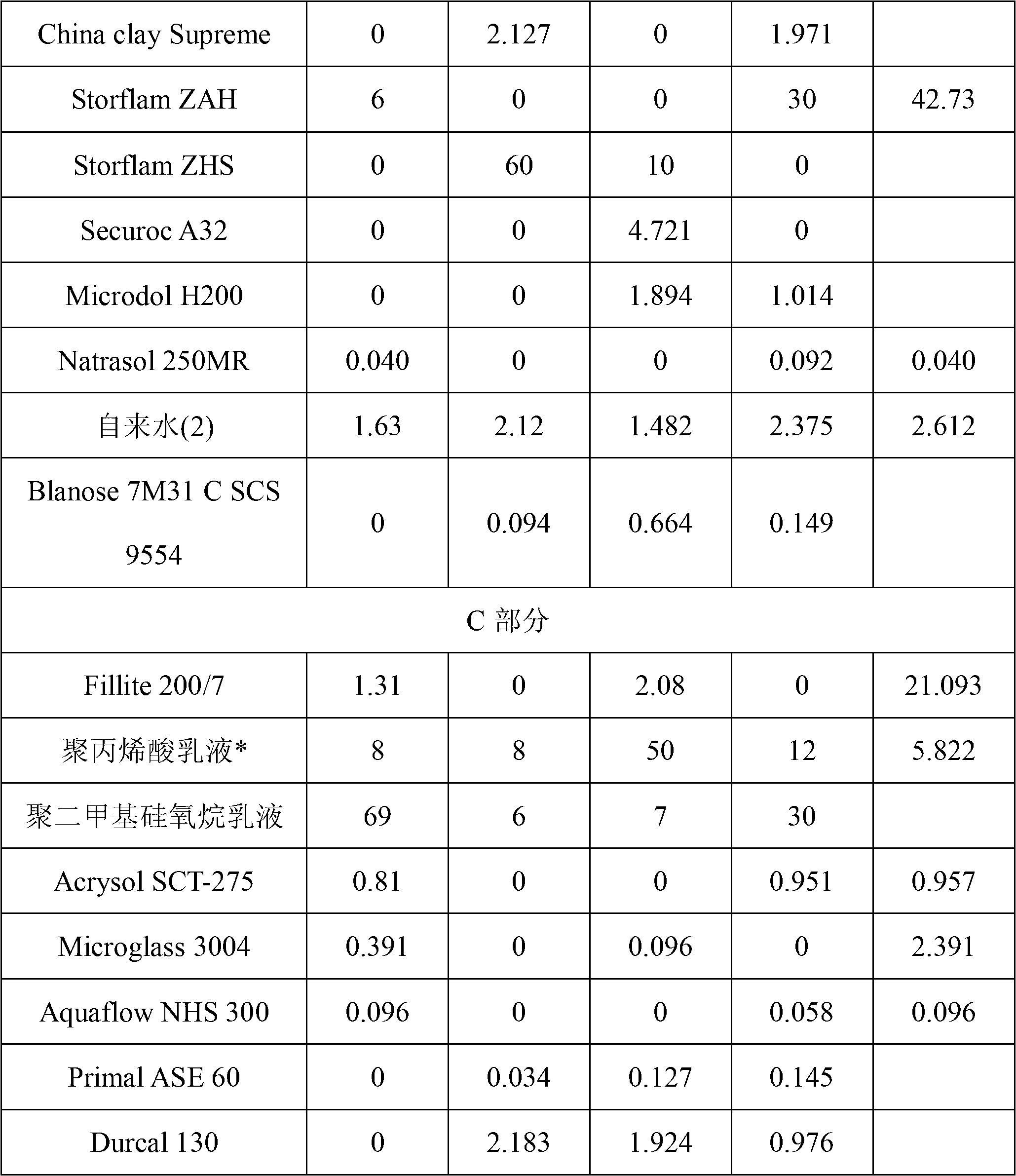

[0078] Add the first part of tap water (1) and Bentone™ EW to a 2.5 liter vessel (150 mm in diameter) fitted with dispersing impeller blades of 100 mm in diameter, maintaining a stirring speed of 500-1000 rpm. Stirring time was continued for approximately 5 minutes until a homogeneous dispersed phase formed without significant agglomeration. Under agitation, the ingredients were added to the mixture in the order listed in Table 1, the amounts of the Part B ingredients also being listed. Add Storflam™ ZAH slowly over 3 minutes. When all ingredients are added to the container, mix at 2000-3000 rpm for fifteen minutes at high speed to evenly disperse the Part A and Part B mixture and form a grind. The components of part C were added in order as shown in Table 1, and at the same time, the Heidolph stirrer equipped with a 100 mm diameter stirring blade was stirred at a slow speed of 350 rpm until a uniform concentration was obtained to form the final coating composition.

Embodiment 2、3 and 4

[0080] Examples 2, 3 and 4 follow the same process as described in Example 1, except that the ingredients and amounts used are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com