Preparation method of silicon-acrylic emulsion capable of being used for preparing polymer cement-based waterproof coating

A waterproof coating, cement-based technology, applied in the direction of cement coatings, coatings, etc., can solve problems such as water resistance and other comprehensive properties that are difficult to meet the above requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

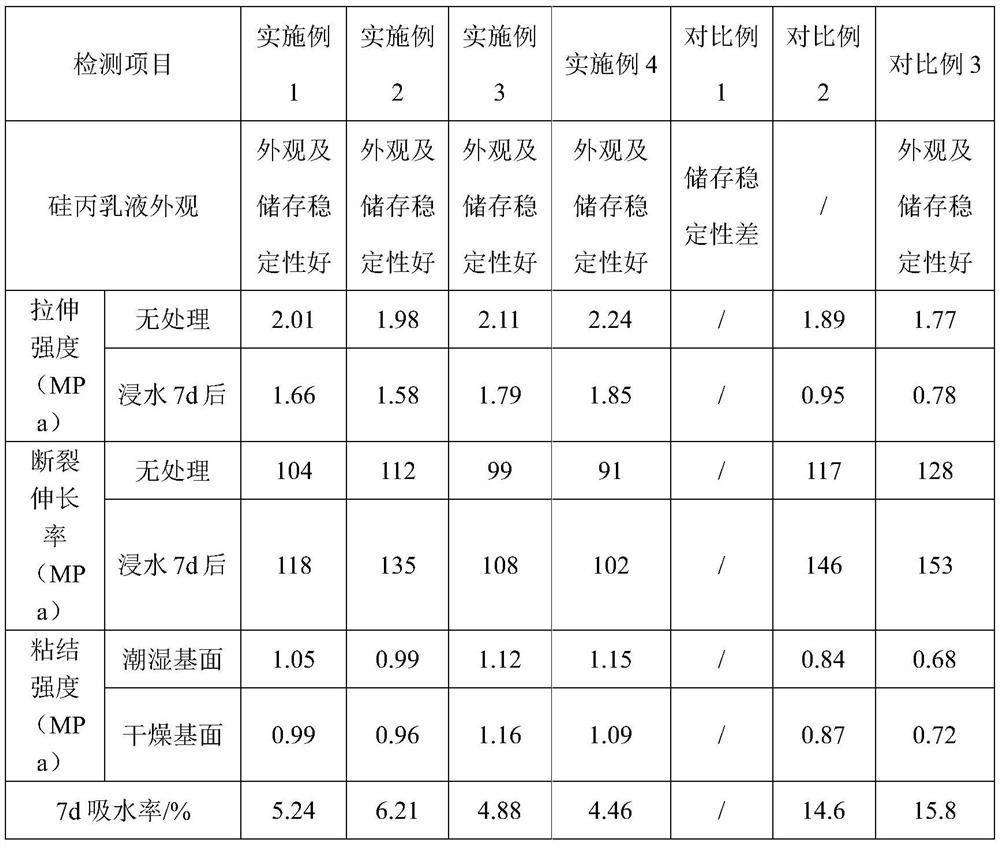

Examples

Embodiment 1

[0020] First, add 0.2 parts of allyloxy nonylphenol polyoxyethylene ether, 0.7 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate into the reactor, anion / nonionic polymerizable emulsifier, 56 parts After the water is stirred evenly, slowly add 10 parts of methacrylic acid and 5 parts of ethyl methacrylate, heat up while stirring, and react at 50°C for 30 minutes to obtain a stable milky white pre-emulsion; adjust the pH value with a pH regulator To 7.5±0.1, heat up to 80°C, then add 1 / 3 of the initiator aqueous solution consisting of 0.5 parts of ammonium persulfate and 16 parts of water dropwise, and the water-soluble initiator aqueous solution of the mixed liquid, and react for a certain period of time to nucleate, Obtain a blue seed emulsion; Slowly add 23 parts of methacrylic acid, 6 parts of ethyl methacrylate, 11 parts of mixed monomers composed of hydroxypropyl acrylate, and 0.5 parts of allyloxynonylphenol Anionic / nonionic polymerizable emulsifier com...

Embodiment 2

[0024] First, add 0.3 parts of allyloxy nonylphenol polyoxyethylene ether, 0.6 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate into the reactor, anion / nonionic polymerizable emulsifier, 56 parts After the water is stirred evenly, slowly add 9 parts of methacrylic acid and 3 parts of ethyl methacrylate, heat up while stirring, and react at 50°C for 30 minutes to obtain a stable milky white pre-emulsion; adjust the pH value with a pH regulator To 7.5±0.1, heat up to 80°C, then add 1 / 3 of the initiator aqueous solution consisting of 0.5 parts of ammonium persulfate and 16 parts of water dropwise, and the water-soluble initiator aqueous solution of the mixed liquid, and react for a certain period of time to nucleate, Obtain blue seed emulsion; Slowly add 24 parts of methacrylic acid, 10 parts of ethyl methacrylate, 8 parts of mixed monomers of hydroxypropyl acrylate, 0.6 parts of allyloxynonylphenol Anionic / nonionic polymerizable emulsifier composed of polyoxy...

Embodiment 3

[0028] First, add 0.3 parts of allyloxy nonylphenol polyoxyethylene ether, 0.5 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate into the reactor, anion / nonionic polymerizable emulsifier, 54 parts After the water is stirred evenly, slowly add 11 parts of methacrylic acid and 4 parts of ethyl methacrylate, heat up while stirring, and react at 50°C for 30 minutes to obtain a stable milky white pre-emulsion; adjust the pH value with a pH regulator To 7.5±0.1, heat up to 80°C, then add 1 / 3 of the initiator aqueous solution consisting of 0.5 parts of ammonium persulfate and 16 parts of water dropwise, and the water-soluble initiator aqueous solution of the mixed liquid, and react for a certain period of time to nucleate, Obtain a blue seed emulsion; Slowly add 22 parts of methacrylic acid, 7 parts of ethyl methacrylate, 12 parts of mixed monomers composed of hydroxypropyl acrylate, and 0.4 parts of allyloxynonylphenol Polyoxyethylene ether, 1.4 parts of anion / non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com