A kind of polyurethane ball court material and preparation method thereof

A polyurethane and court technology, which is applied in the field of polyurethane court materials and their preparation, can solve the problems of non-conformity with environmental protection concepts and high toxicity, and achieve the effects of good hydrolysis resistance stability, low cohesive energy and good curing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

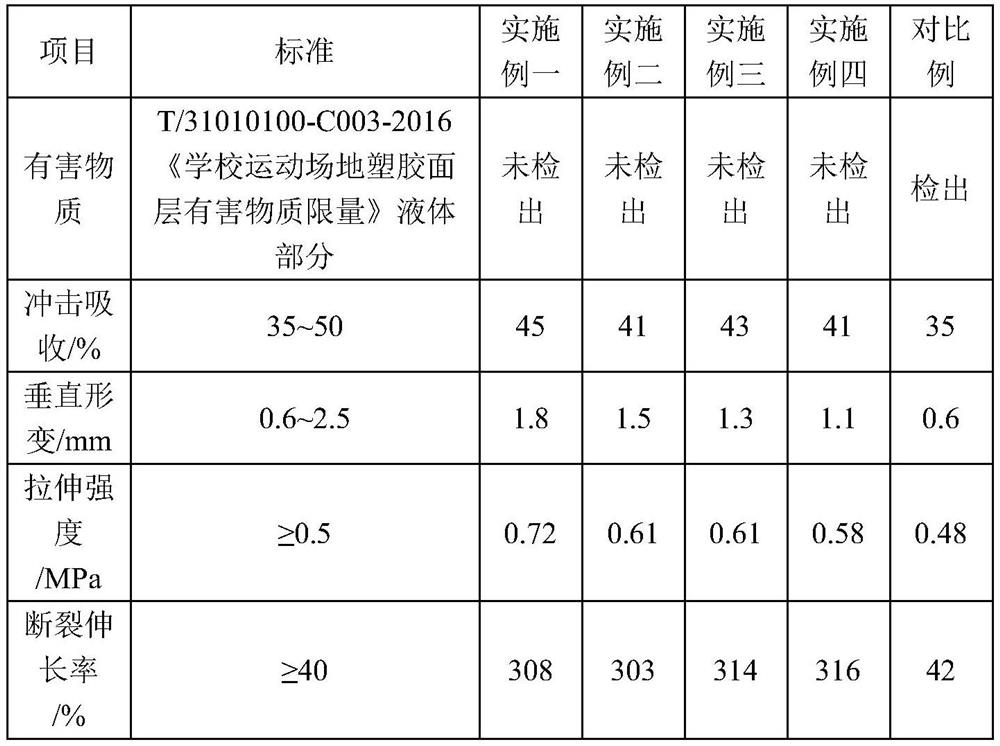

Examples

Embodiment 1

[0038] (1) According to parts by weight, select 75 parts of polyoxypropylene polyol, 25 parts of polytetrahydrofuran diol, 8 parts of diphenylmethane diisocyanate, 15 parts of mineral powder, 15 parts of calcined clay, and 20 parts of dearomatized solvent oil part, 0.05 part of composite catalyst for batching;

[0039] (2) Add 75 parts of polyoxypropylene polyol, 25 parts of polytetrahydrofuran diol, 15 parts of mineral powder, 15 parts of calcined clay and 20 parts of aromatic hydrocarbon solvent oil into the dehydration kettle, and dehydrate under reduced pressure at 115 ° C. The vacuum degree is -0.09MPa, and the extracted solvent and water are condensed and collected. After the solvent and water are separated, the solvent is recovered and reused;

[0040] (3) After the dehydration is completed, the temperature is lowered to 75° C., and 8 parts of diphenylmethane diisocyanate and 0.05 part of composite catalyst are added, and the reaction is carried out for 2 hours;

[004...

Embodiment 2

[0043] (1) According to parts by weight, select 60 parts of polyoxypropylene polyol, 20 parts of polytetrahydrofuran diol, 10 parts of diphenylmethane diisocyanate, 10 parts of mineral powder, 10 parts of calcined clay, and 15 parts of dearomatized solvent oil , 0.07 parts of composite catalyst and 2 parts of auxiliary agent for batching;

[0044] (2) Add 60 parts of polyoxypropylene polyol, 20 parts of polytetrahydrofuran diol / 10 parts of mineral powder, 10 parts of calcined clay and 15 parts of dearomatized solvent oil into the dehydration kettle, dehydrate under reduced pressure at 115 ° C, and control The vacuum degree is -0.09MPa, and the extracted solvent and water are condensed and collected. After the solvent and water are separated, the solvent is recovered and reused.

[0045] (3) After the dehydration is completed, the temperature is lowered to 75°C, and 10 parts of diphenylmethane diisocyanate and 0.07 parts of composite catalyst are added, and the reaction is carr...

Embodiment 3

[0048] (1) According to parts by weight, select 45 parts of polyoxypropylene polyols, 15 parts of polytetrahydrofuran diol, 12 parts of diphenylmethane diisocyanate, 7 parts of mineral powder, 8 parts of calcined clay, and 20 parts of dearomatized solvent oil part, 0.08 part of composite catalyst and 2 parts of auxiliary agent for batching;

[0049] (2) Add 45 parts of polyoxypropylene polyol, 15 parts of polytetrahydrofuran diol, 7 parts of mineral powder, 8 parts of calcined clay and 20 parts of dearomatized solvent oil into the dehydration kettle, and dehydrate under reduced pressure at 115 ° C. The vacuum degree is -0.09MPa, and the extracted solvent and water are condensed and collected. After the solvent and water are separated, the solvent is recovered and reused;

[0050] (3) After the dehydration is completed, the temperature is lowered to 75° C., and 12 parts of diphenylmethane diisocyanate and 0.08 parts of composite catalyst are added, and the reaction is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com