Environmental-protection flame retardant cable material and preparation method thereof

A flame-retardant cable, green and environmentally friendly technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor low-temperature performance and high cost, and achieve improved low-temperature performance, excellent oil resistance, transparency and surface gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

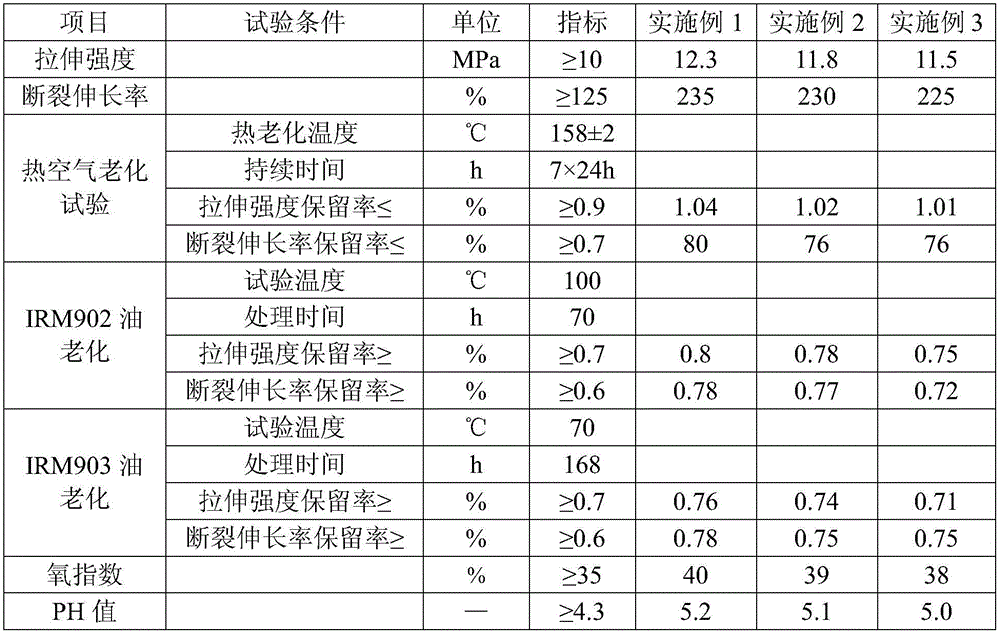

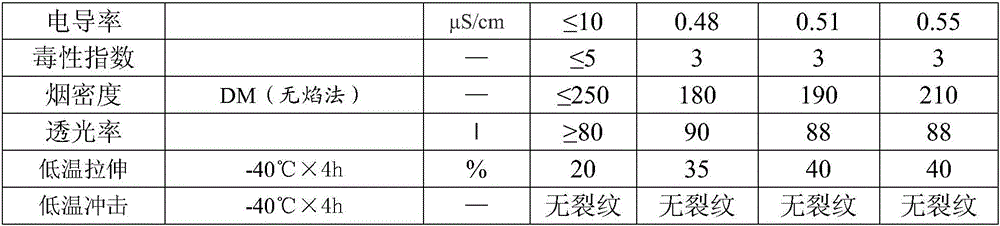

Examples

Embodiment 1

[0026] A green and environment-friendly flame-retardant cable material, the components contained therein and the parts by weight of each component are as follows:

[0027] 60 parts of ethylene-vinyl acetate rubber, 40 parts of EPDM rubber, 10 parts of zinc oxide, 3 parts of anti-aging agent, 1 part of lubricant, 5 parts of zinc borate, 10 parts of pigment carbon black, 170 parts of active flame retardant, 5 parts of processing aid, 1 part of co-crosslinking agent, 3 parts of peroxide crosslinking agent.

Embodiment 2

[0029] A green and environment-friendly flame-retardant cable material, the components contained therein and the parts by weight of each component are as follows:

[0030] 70 parts of ethylene-vinyl acetate rubber, 30 parts of EPDM rubber, 8 parts of zinc oxide, 3.5 parts of anti-aging agent, 1.5 parts of lubricant, 8 parts of zinc borate, 12 parts of pigment carbon black, 150 parts of active flame retardant, 8 parts of processing aid, 1 part of co-crosslinking agent, 3.5 parts of peroxide crosslinking agent.

Embodiment 3

[0032] A green and environment-friendly flame-retardant cable material, the components contained therein and the parts by weight of each component are as follows:

[0033] 60 parts of ethylene-vinyl acetate rubber, 50 parts of EPDM rubber, 10 parts of zinc oxide, 3.5 parts of anti-aging agent, 2 parts of lubricant, 10 parts of zinc borate, 15 parts of pigment carbon black, 180 parts of active flame retardant, 10 parts of processing aid, 1.5 parts of auxiliary crosslinking agent, 4 parts of peroxide crosslinking agent.

[0034] The auxiliary crosslinking agent and peroxide crosslinking agent in the above-mentioned embodiment are not specifically limited, and various suitable auxiliary crosslinking agents and peroxide crosslinking agents can be used, as long as they do not have an adverse effect on the purpose of the present invention. . Auxiliary cross-linking agents such as TAC, HVA-2, TAIC, etc., peroxide cross-linking agents such as DCP, odorless DCP, double 25, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com