Semi-aromatic nylon modified composite material and preparation method thereof

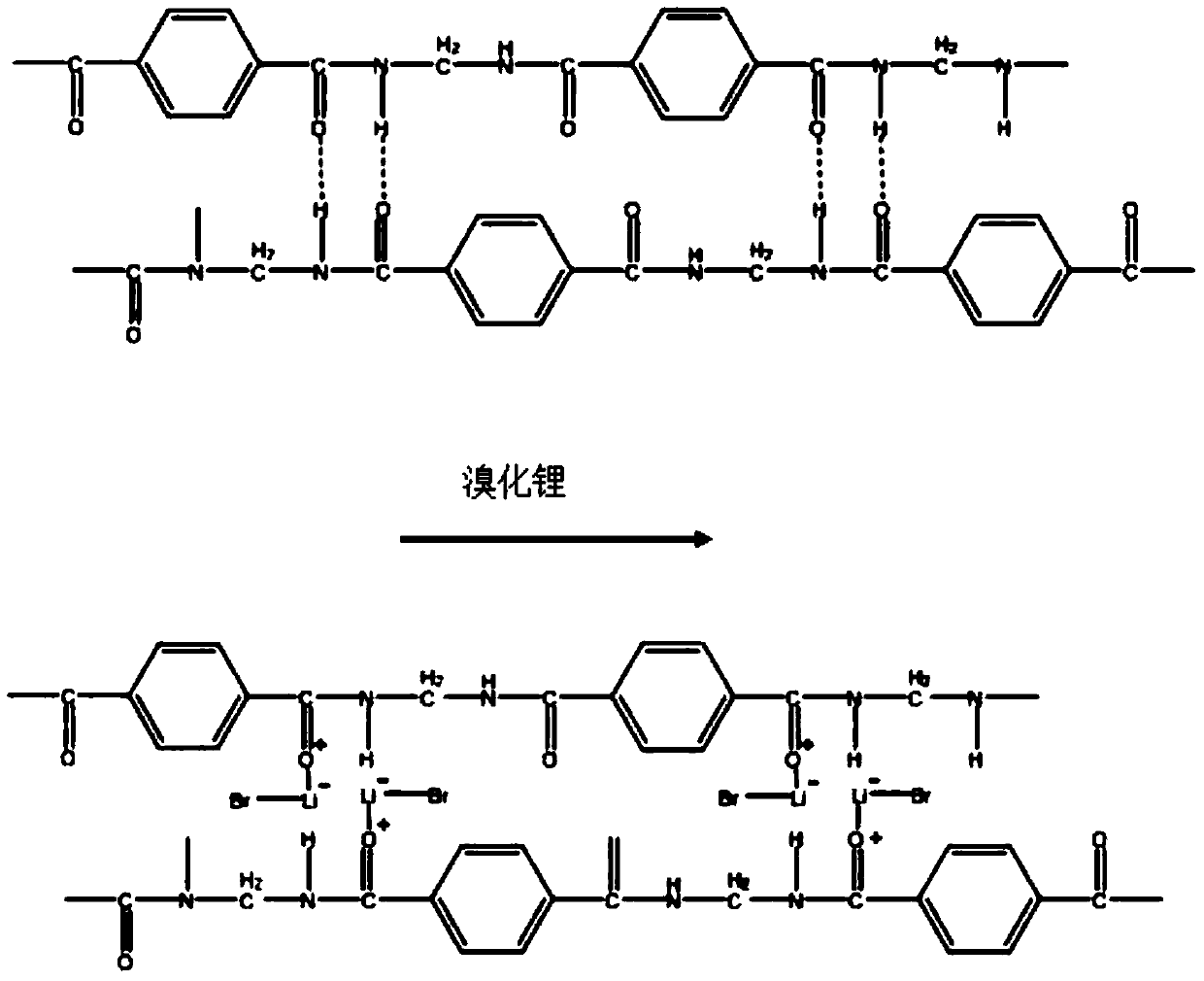

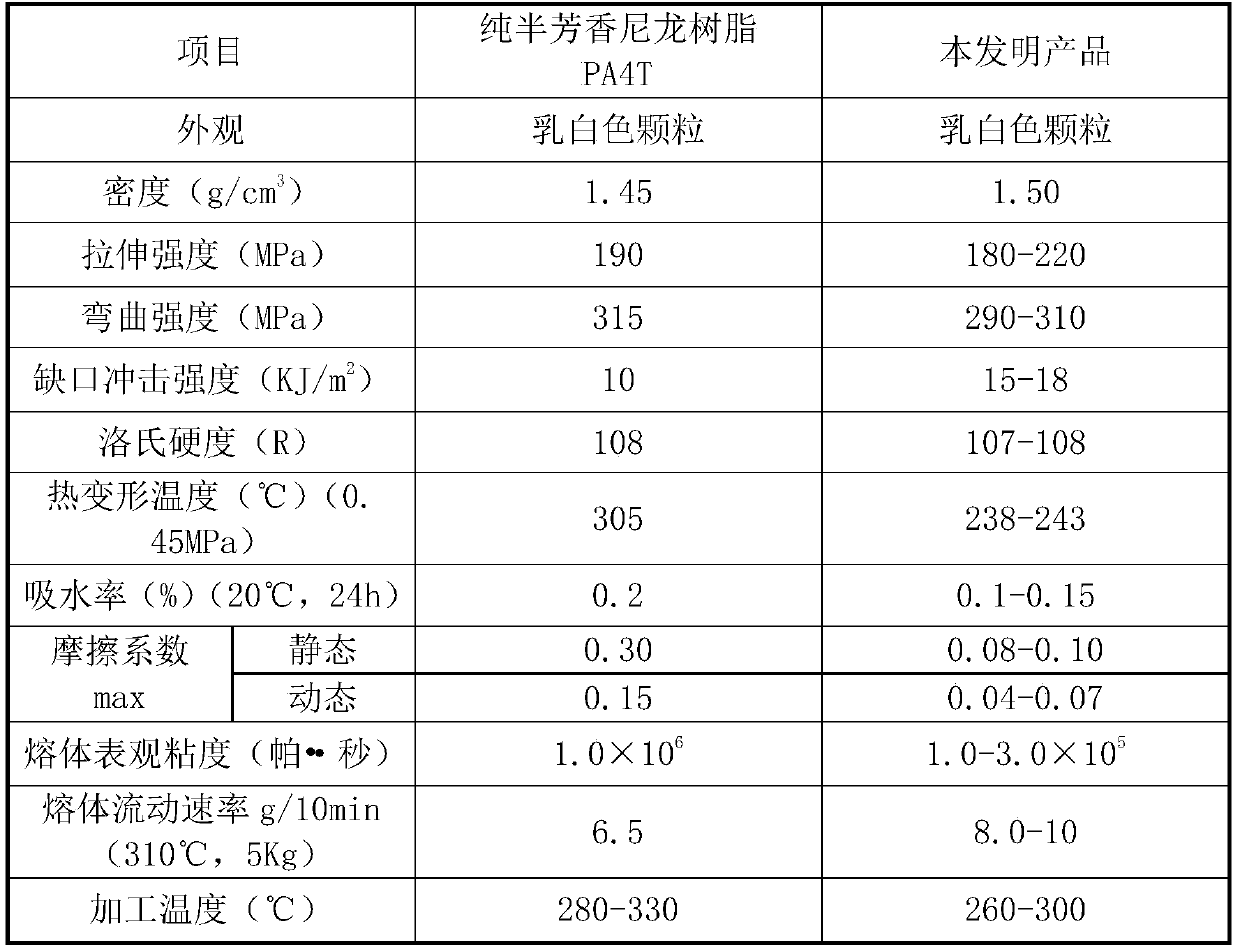

The technology of semi-aromatic nylon and composite material is applied in the field of semi-aromatic nylon modified composite material and its preparation, which can solve the problems of restricting the application of high-temperature resistant nylon, difficult plastic processing equipment processing, expensive nylon and the like, and achieves cohesion. Can reduce, reduce melt viscosity, improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

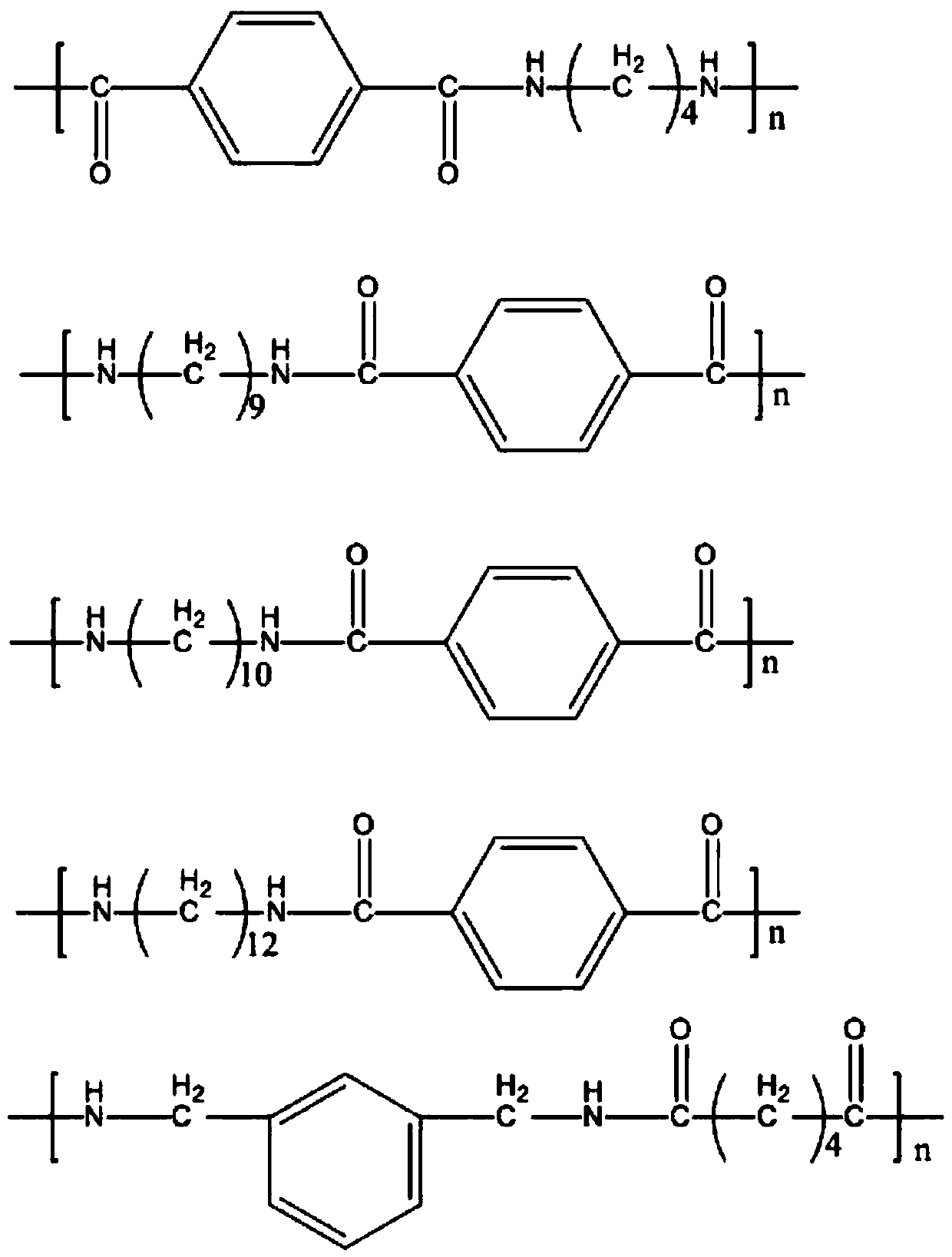

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a semi-aromatic nylon modified composite material, specifically: mixing the dried semi-aromatic nylon resin, lithium halide, and additives according to the required ratio, and then discharging them into a parallel twin-screw extruder for melt blending and extruding It can be granulated.

[0027] The raw material composition of the composite material also includes silane-modified calcium sulfate whiskers, the weight ratio of which to semi-aromatic nylon resin is 15-25:80-100, and the silane-modified calcium sulfate whiskers are prepared according to the following method get:

[0028] The anhydrous dead-burned calcium sulfate whisker, the crystal form modifier and the surface modifier are mixed, followed by washing, filtering and drying in sequence to obtain the silane-modified calcium sulfate whisker.

[0029] In the preparation method of the composite material, the extrusion process temperature of the twin-screw extruder is: 250±5°C in the first ...

Embodiment 1

[0048] A semi-aromatic nylon modified composite material, its raw material composition and weight ratio are: semi-aromatic nylon resin PA4T 80, lithium bromide 2, silane-modified calcium sulfate whisker 15, polytetrafluoroethylene micropowder 1, cyclic poly Ester 3, antioxidant 10760.3, antioxidant 168 0.3, wherein, the raw material composition and weight ratio of the silane-modified calcium sulfate whisker are: anhydrous dead-burned calcium sulfate whisker 80, dodecyl Trimethoxysilane 1, lithium chloride 2, liquid paraffin 1.

[0049] The above-mentioned composite material is prepared according to the following steps in turn:

[0050] Step 1. First add anhydrous dead-burned calcium sulfate whiskers and lithium chloride into the mixer according to the required ratio, set the temperature of the mixer at 105°C, stir at 950 rpm, and then add liquid paraffin The diluted dodecyltrimethoxysilane was stirred for 15 minutes, then the mixture was taken out, washed with water, filtered...

Embodiment 2

[0053] The difference with Example 1 is:

[0054] The raw material composition and weight ratio of the composite material are: semi-aromatic nylon resin PA4T 100, lithium bromide 3, silane-modified calcium sulfate whisker 25, polytetrafluoroethylene micropowder 2, cyclic polyester 5, antioxidant 1076 0.5. Antioxidant 168 0.5, wherein the raw material composition and weight ratio of the silane-modified calcium sulfate whiskers are: anhydrous dead-burned calcium sulfate whiskers 100, dodecyltrimethoxysilane 3, Lithium chloride 4, liquid paraffin 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com