High-concentration waste sulfuric acid treatment method and system

A treatment method and technology of a treatment system are applied in the field of high-concentration waste sulfuric acid treatment methods and systems, which can solve the problems of low recovery rate of high-concentration waste sulfuric acid, and achieve the advantages of reducing later evaporation, reducing production energy consumption, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

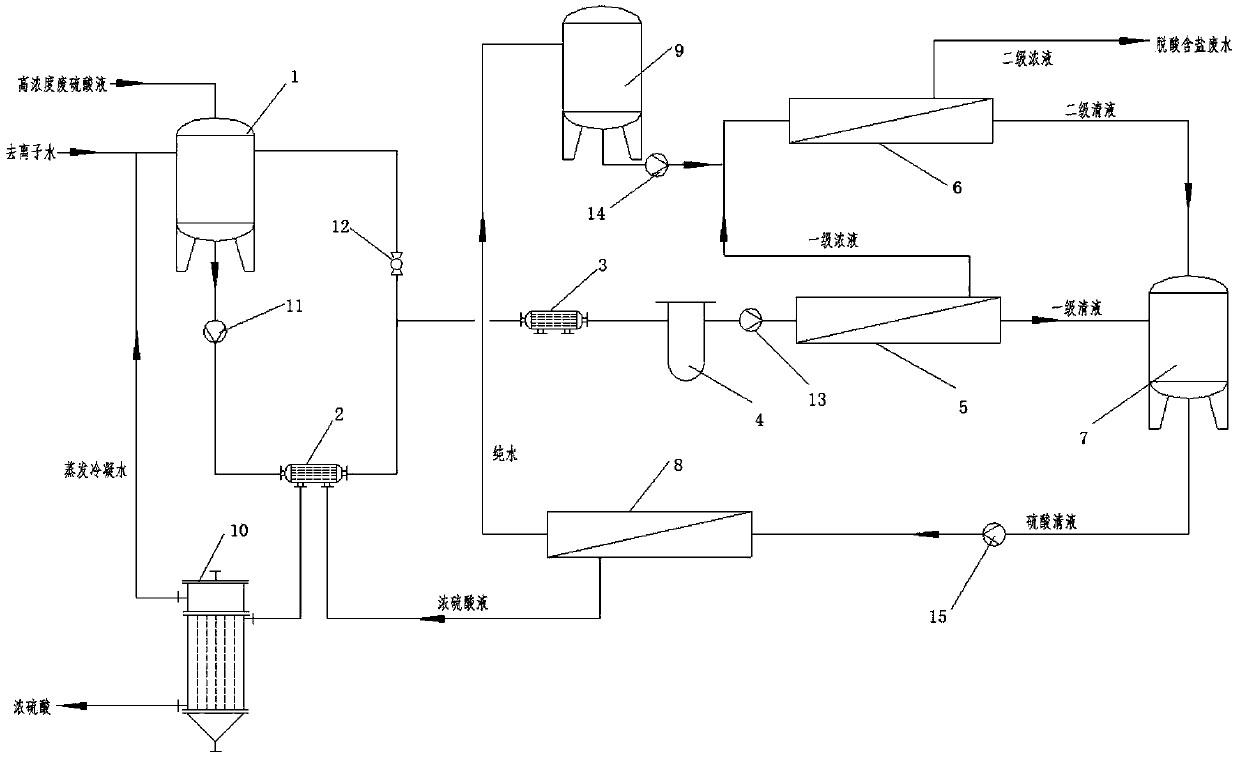

[0078] The waste sulfuric acid solution with a sulfuric acid concentration of 40% and an impurity content of 15% or less enters the concentration adjustment tank 1. According to the concentrated sulfuric acid concentration and the adjusted concentration, deionized water is added to make the adjusted sulfuric acid concentration 20%. Concentrated sulfuric acid will release a large amount of heat when it is diluted. If the heat is not taken away, a large amount of acidic vapor will be generated, which will cause serious corrosion to the equipment, and it is more dangerous. The present invention uses the first high-pressure pump 11 and the first heat exchanger 2 outside the concentration adjustment tank 1 to collect the heat generated in the waste sulfuric acid dilution process and exchange heat with the sulfuric acid solution after purification and concentration in the subsequent stage, which not only reduces the concentration adjustment tank The temperature of the sulfuric acid so...

Embodiment 2

[0087] The waste sulfuric acid solution with a sulfuric acid concentration of 50% and an impurity content of less than 10% enters the concentration adjustment tank 1. According to the concentrated sulfuric acid concentration and the adjusted concentration, deionized water is added to make the adjusted sulfuric acid concentration 20%. Concentrated sulfuric acid will release a large amount of heat when it is diluted. If the heat is not taken away, a large amount of acidic vapor will be generated, which will cause serious corrosion to the equipment, and it is more dangerous. The present invention uses the first high-pressure pump 11 and the first heat exchanger 2 outside the concentration adjustment tank 1 to collect the heat generated in the waste sulfuric acid dilution process and exchange heat with the sulfuric acid solution after purification and concentration in the subsequent stage, which not only reduces the concentration adjustment tank The temperature of the sulfuric acid ...

Embodiment 3

[0096] The waste sulfuric acid solution with a sulfuric acid concentration of 55% and an impurity content of 5% or less enters the concentration adjustment tank 1, and according to the concentrated sulfuric acid concentration and the adjusted concentration, deionized water is added to make the adjusted sulfuric acid concentration 20%. Concentrated sulfuric acid will release a large amount of heat when it is diluted. If the heat is not taken away, a large amount of acidic vapor will be generated, which will cause serious corrosion to the equipment, and it is more dangerous. The present invention uses the first high-pressure pump 11 and the first heat exchanger 2 outside the concentration adjustment tank 1 to collect the heat generated in the waste sulfuric acid dilution process and exchange heat with the sulfuric acid solution after purification and concentration in the subsequent stage, which not only reduces the concentration adjustment tank The temperature of the sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com