Homogenizing and dispersing equipment used for high-rate LiFePO4 soft package lithium ion power battery

A power battery, lithium ion technology, applied in the field of homogenizing and dispersing equipment, can solve the problems of difficult uniform dispersion, inability to coat, low solid content, etc., and achieve the effects of reducing mixing difficulty, improving mixing effect, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

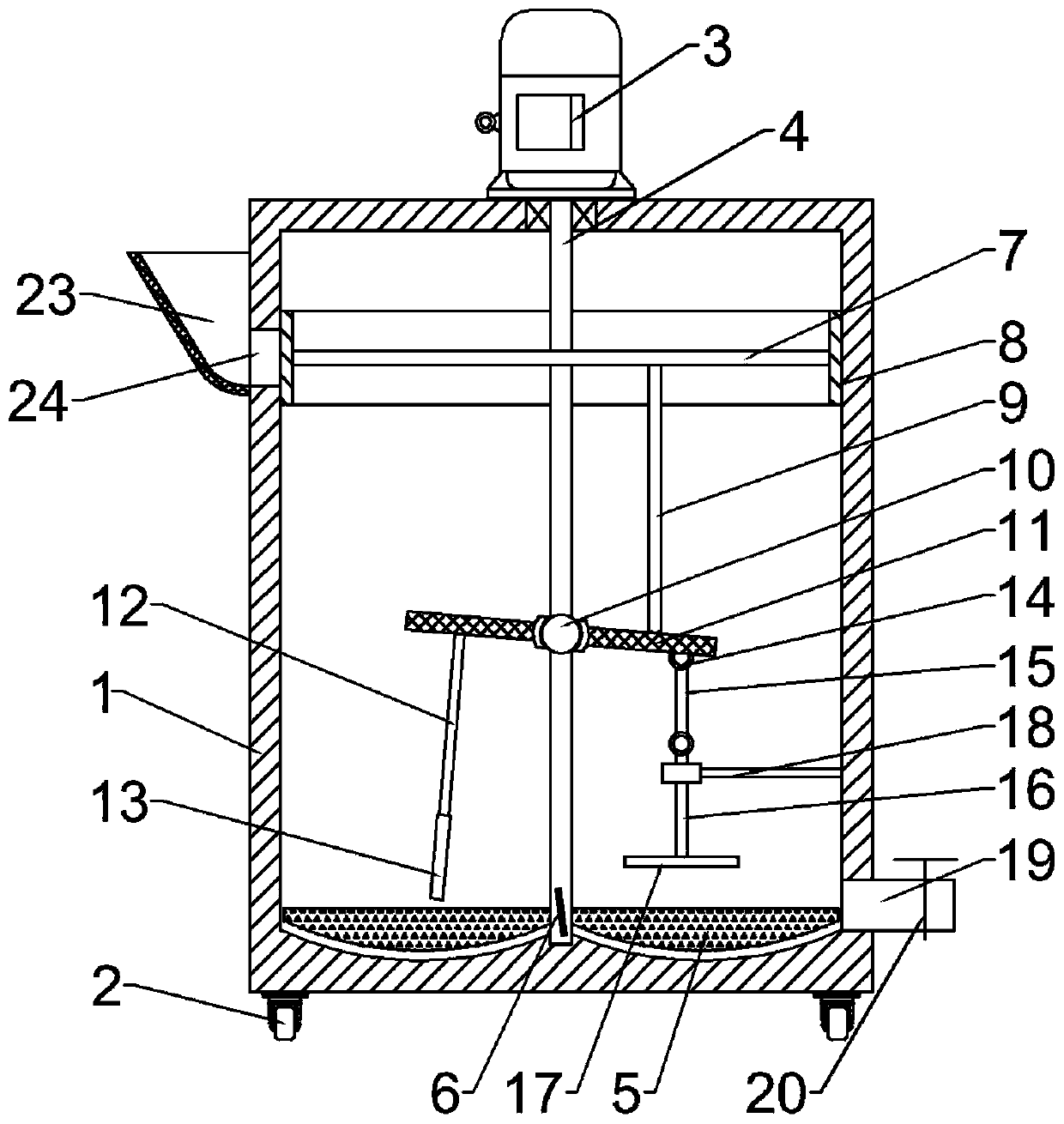

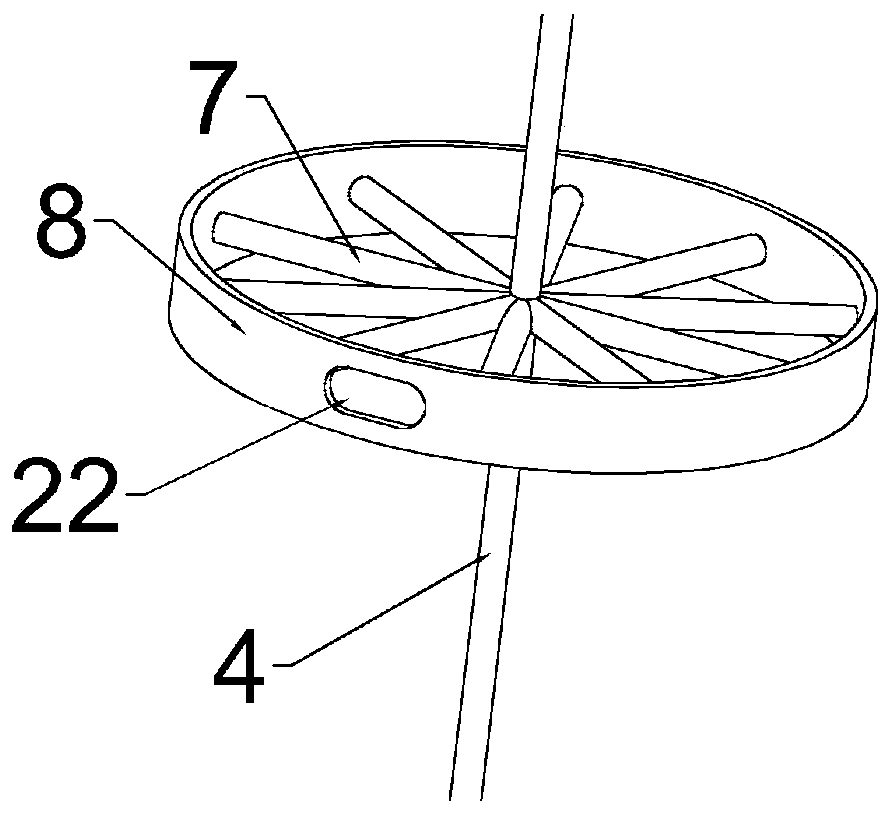

[0021] Example 1: Please refer to Figure 1-3 , a homogenizing and dispersing device for high-rate LiFePO4 soft-packed lithium-ion power batteries, comprising a box body 1, a motor 3 is fixedly connected to the top of the box body 1, and a longitudinal shaft 4 is fixedly connected to the output end of the motor 3, and the longitudinal shaft 4 The left and right sides of the bottom are fixedly connected with longitudinal stirring blades 5, the longitudinal shaft 4 is symmetrically fixedly connected with inclined stirring blades 6, the top of the longitudinal shaft 4 is fixedly connected with spokes 7, and the outer side of the spokes 7 is fixedly connected with an annular rotating plate 8, the annular Turning plate 8 is provided with feeding through-hole 22, and above described casing 1 outer side is fixedly connected with guide hopper 23, and is provided with feeding hole 24 on casing 1 below feeding hopper 23 inner side, and feeding hole 24 is connected with feeding passageway...

Embodiment 2

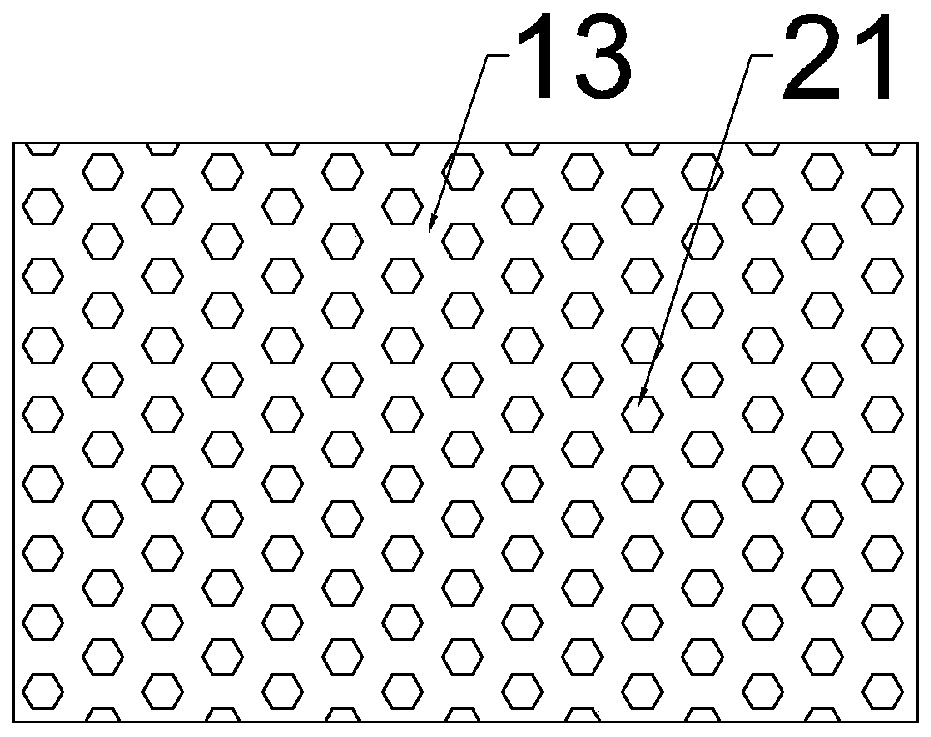

[0033] Embodiment 2: This embodiment is a further improvement of the previous embodiment: a number of mixing holes 21 are provided on the first mixing plate 13 and the second mixing plate 17, and the setting of the mixing holes 21 makes the first The mixing plate 13 and the second mixing plate 17 continuously separate and recombine the original pulp during the movement, further improving the mixing effect.

[0034] The working principle of the present invention is: place the raw pulp in the guide hopper 23, then turn on the motor 3, the rotation of the motor 3 drives the rotation of the longitudinal shaft 4, and the rotation of the longitudinal shaft 4 can drive the rotation of the ring-shaped rotary plate 8 through the spokes 7, and then The feeding through hole 22 and the feeding hole 24 overlap periodically to realize intermittent feeding. The raw slurry is mixed and stirred by the vertical stirring blade 5 and the inclined stirring blade 6 at the bottom of the box body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com